Simple wrench for fastening lower bolt of T-shaped beam side template

A side formwork and bolt technology, which is applied in the field of simple wrench fastening bolts at the lower part of the T-beam side formwork, can solve problems such as increased project cost, inability to fasten nuts, and damage to the strength of the T-beam, so as to improve work efficiency and save installation time , Guarantee the effect of prefabricated quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

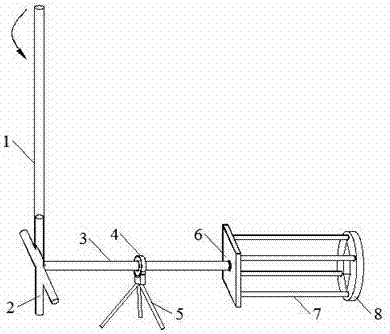

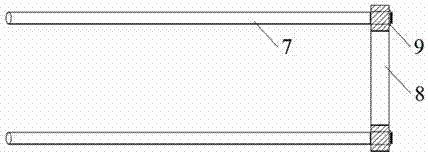

[0036] Embodiment 1: as Figure 1-6 As shown, a simple wrench for fastening bolts at the lower part of the T-beam side formwork, including a torsion bar 1, a cross bar 2, a dowel bar 3, a bearing 4, a triangle bracket 5, a force transmission steel plate 6, a dispersed dowel bar 7, and a nut Kit 8 and hex thin nut 9;

[0037] According to the different sizes of the pull bolts at the lower part of the T-beam side formwork, make nut kits 8 of different sizes in advance; determine the length of each part of the simple wrench according to the operator's comfort level for fastening the bolts. On the nut set 8, four reserved holes are evenly arranged along the axis of the circular ring, and four scattered dowel rods 7 pass through the reserved holes, and are fixed with hexagonal thin nuts 9 at the bottom of the nut set. When the size of the bolts at the lower part of the T-beam side formwork is changed, only the appropriate nut set 8 needs to be replaced.

[0038] The head size of ...

Embodiment 2

[0051] Embodiment 2: as Figure 1-6 As shown, a simple wrench for fastening bolts at the lower part of the T-beam side formwork, including a torsion bar 1, a cross bar 2, a dowel bar 3, a bearing 4, a triangle bracket 5, a force transmission steel plate 6, a dispersed dowel bar 7, and a nut Kit 8 and hex thin nut 9;

[0052] According to the different sizes of the pull bolts at the lower part of the T-beam side formwork, make nut kits 8 of different sizes in advance; determine the length of each part of the simple wrench according to the operator's comfort level for fastening the bolts. On the nut set 8, four reserved holes are evenly arranged along the axis of the circular ring, and four scattered dowel rods 7 pass through the reserved holes, and are fixed with hexagonal thin nuts 9 at the bottom of the nut set. When the size of the bolts at the lower part of the T-beam side formwork is changed, only the appropriate nut set 8 needs to be replaced.

[0053] The head size of ...

Embodiment 3

[0066] Embodiment 3: as Figure 1-6 As shown, a simple wrench for fastening bolts at the lower part of the T-beam side formwork, including a torsion bar 1, a cross bar 2, a dowel bar 3, a bearing 4, a triangle bracket 5, a force transmission steel plate 6, a dispersed dowel bar 7, and a nut Kit 8 and hex thin nut 9;

[0067] According to the different sizes of the pull bolts at the lower part of the T-beam side formwork, make nut kits 8 of different sizes in advance; determine the length of each part of the simple wrench according to the operator's comfort level for fastening the bolts. On the nut set 8, four reserved holes are evenly arranged along the axis of the circular ring, and four scattered dowel rods 7 pass through the reserved holes, and are fixed with hexagonal thin nuts 9 at the bottom of the nut set. When the size of the bolts at the lower part of the T-beam side formwork is changed, only the appropriate nut set 8 needs to be replaced.

[0068] The head size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com