Maglev curved track beam mechanical formwork system and using method

A curved track and mechanical technology, applied in the direction of molds, ceramic molding machines, mold auxiliary parts, etc., can solve the problems of low splicing efficiency and poor reliability, and achieve the effect of improving prefabrication efficiency, low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

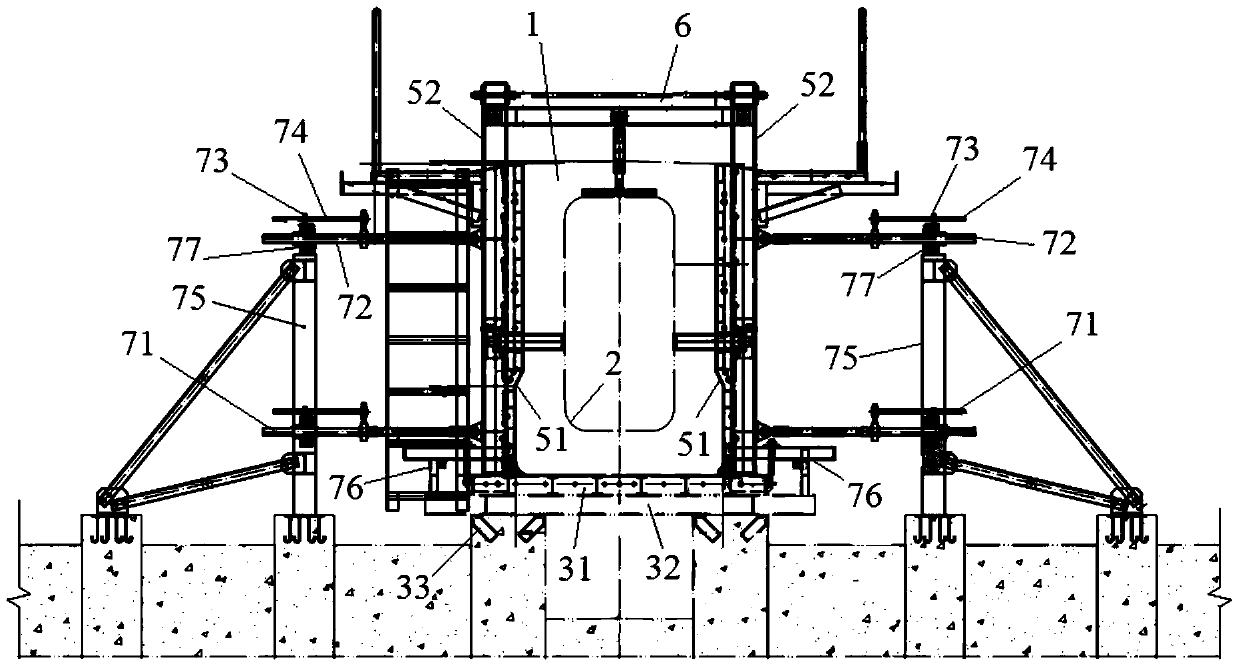

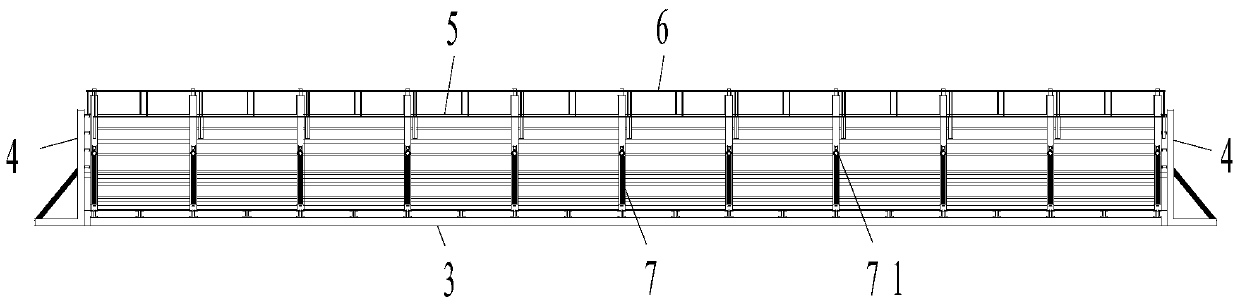

[0052] Such as Figure 1-3 As shown, a maglev curved track beam mechanical formwork system includes:

[0053] Bottom form 3, used for carrying track beam 1;

[0054] The side form 5 includes bendable side form panels 51 arranged along the longitudinal sides of the track beam 1, and several skeletons 52 are arranged on the outside of each side form panel 51;

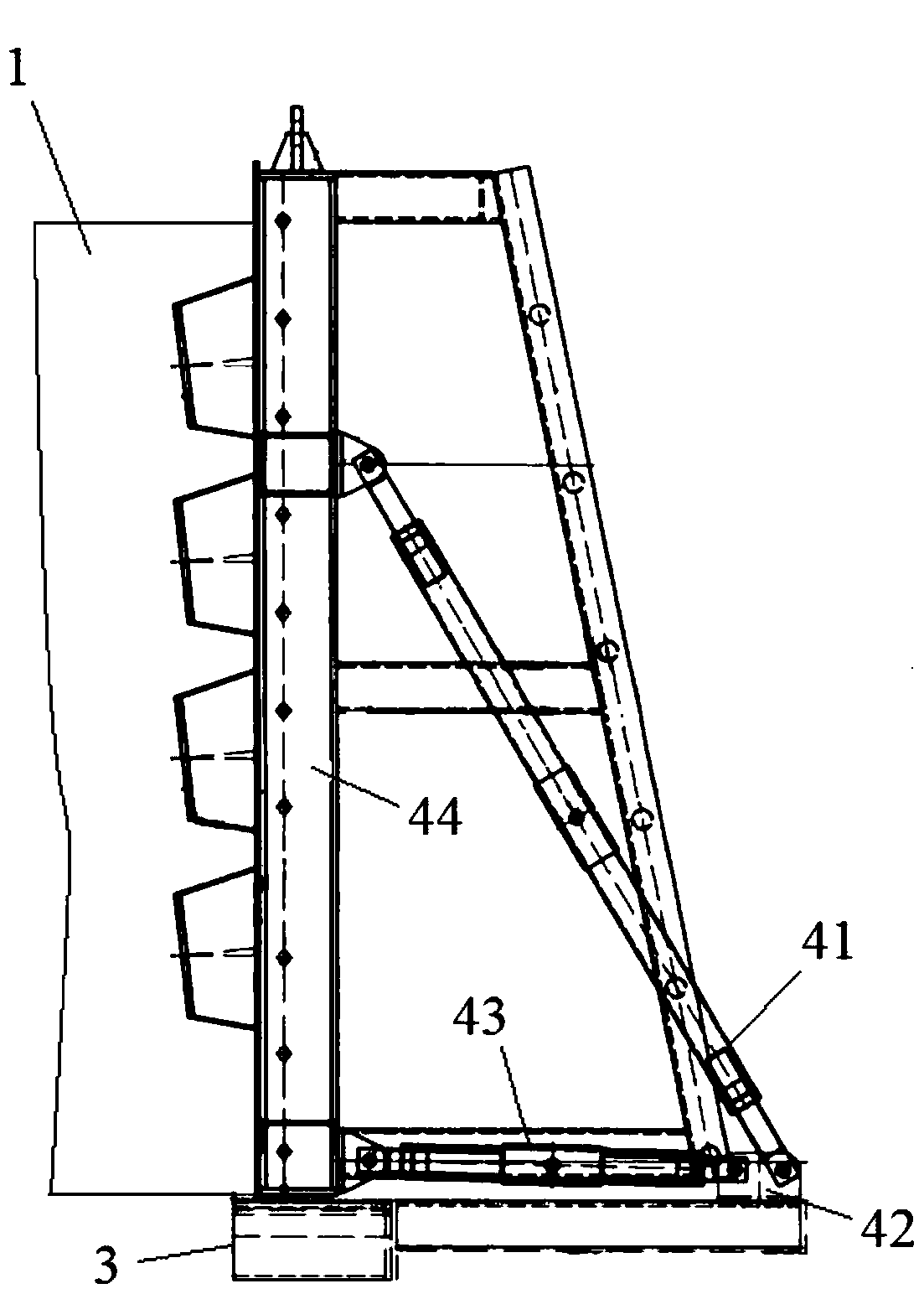

[0055] The end mold 4 is arranged along the two ends of the track beam 1, and the outer side of the end mold 4 is provided with a translation assembly 43 capable of longitudinally translating the end mold 4 along the track beam 1;

[0056] And the adjustment part 7, including at least two mechanical push rod assemblies 71 arranged on the outside of each frame 52, each mechanical push rod assembly 71 is used to adjust the lateral displacement of the corresponding frame 52 relative to the track beam 1 and the verticality relative to the bottom mold 3 .

[0057] Such as figure 1 , 4 As shown, each of the above-mentioned...

Embodiment 2

[0065] Such as Figure 1-5 As shown, the present invention also provides a method for using the maglev curved track beam mechanical formwork system, including the maglev curved track beam mechanical formwork system in Example 1, and the use method includes the following steps:

[0066] Step 1, install the base form 3, and install the base form 3 at the beam making site;

[0067] Step 2, install the side form 5, weld all the skeletons 52 on the side mold panel 51, connect the adjustment parts 7 on the skeleton 52, that is, install at least two mechanical push rod assemblies 71 on each of the skeletons 52;

[0068] Step 3, adjusting the curvature of the side mold 5, adjusting each of the mechanical push rod assemblies 71, so that the skeleton 52 corresponding to each of the mechanical push rod assemblies 71 is laterally displaced or rotated relative to the bottom mold 3, so that The skeleton 52 meets the position of the accuracy requirement, so that the entire side form panel 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com