A prefabricated combined steel mold for reinforced concrete arch slab and its assembly process

A reinforced concrete and concrete technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of slow prefabrication, long construction period, short service life of formwork, etc., and reach the number of formwork The effect of reduced investment, convenient operation for workers, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

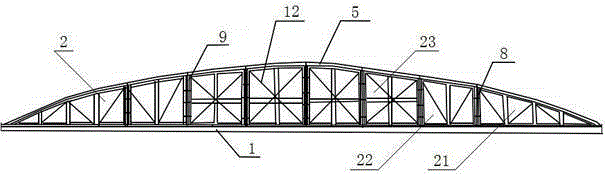

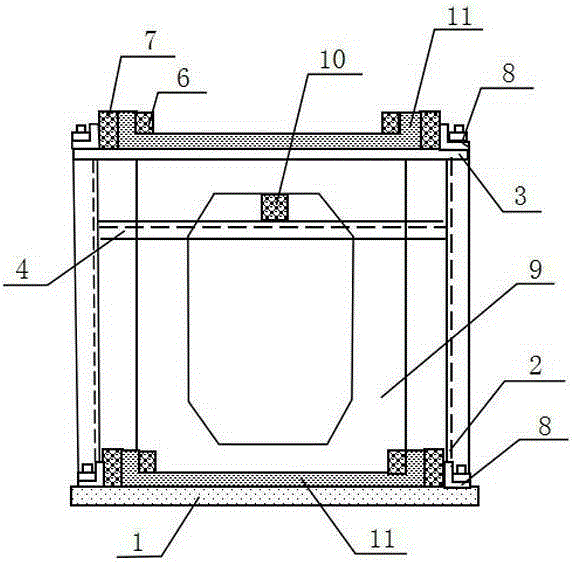

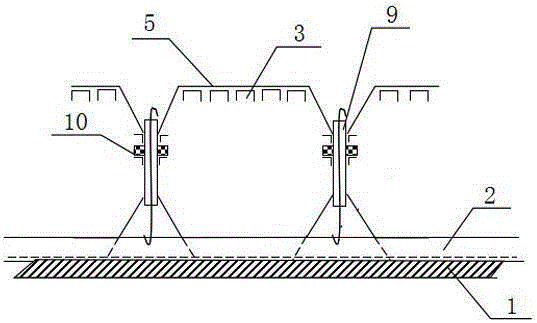

[0015] Such as figure 1 , 2 , a reinforced concrete arch slab prefabricated combined steel form shown in 3, including a cement floor form 1, which is installed on the cement floor form through anchor bolts. Two sets of arch plate support assemblies 2 located on both sides of the cement floor form are installed by bolt A number of joists 3 and connecting rods 4 used to connect the two groups of arch slab support assemblies, a number of upper arch bottom forms 5 installed on the joists, installed on the cement floor form 1 and the joists 3 for internal use The inner mold 6 and the outer mold 7 fixed by the card and the outer card; the arch plate support assembly 2 is composed of the arch head 21, the arch body 22 and the arch top 23 connected by bolts 8; the adjacent upper arch bottom mold 5 is installed There are partitions 9.

[0016] The partition plate 9 and the connecting rod 4 are fixed by a wedge 10 .

[0017] A concrete layer 11 is poured between the inner mold 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com