Prefabrication production method of prestressed concrete wind power generation tower drum

A production method and concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of low production efficiency and high cost, and achieve the effect of low cost, low initial investment and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

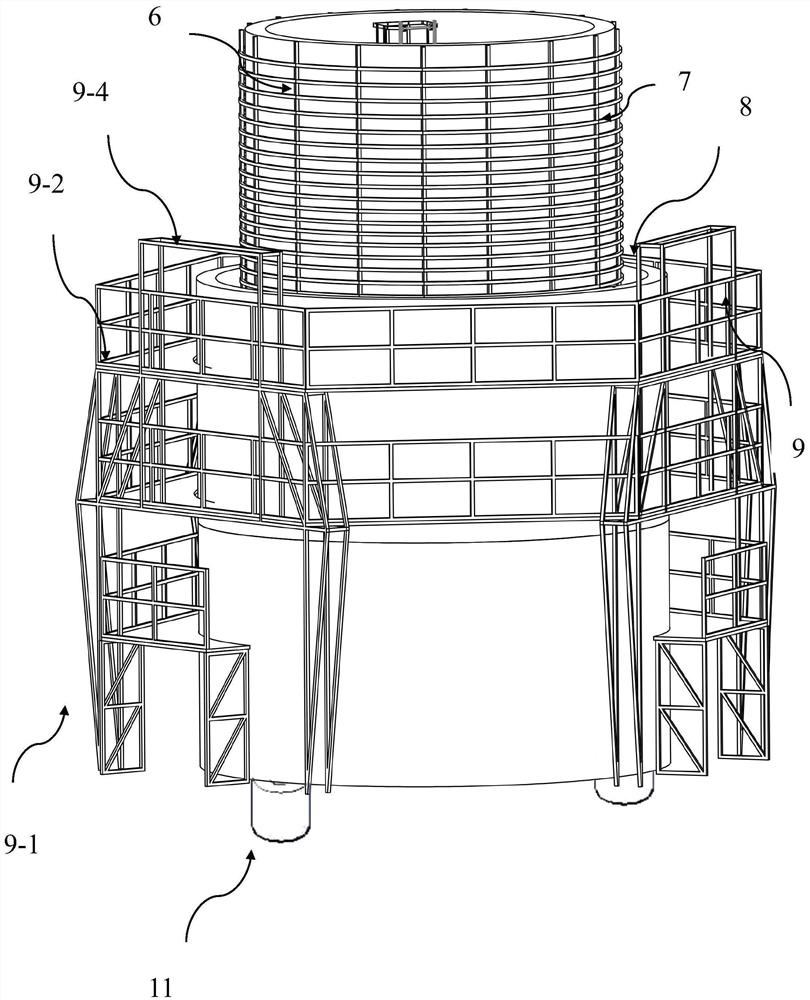

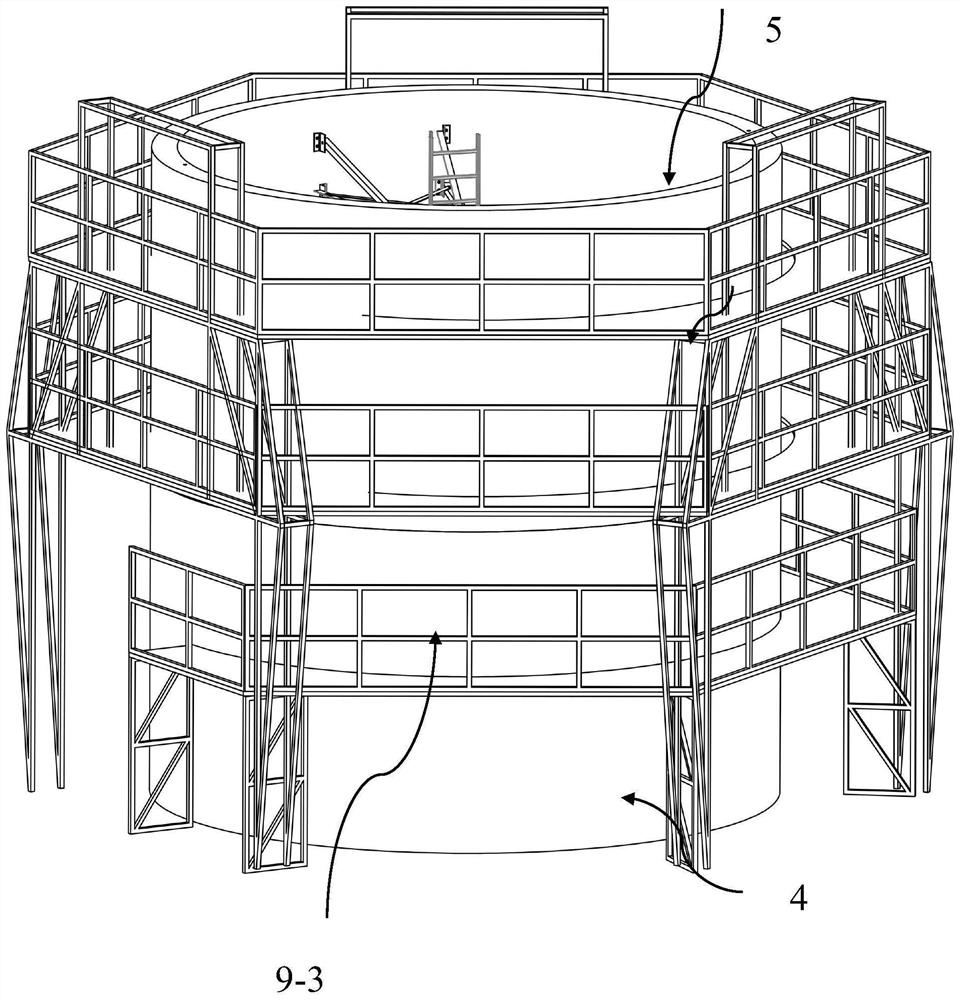

[0029] Such as Figure 2~4 Shown, a kind of prefabricated production method of prestressed concrete wind power generation tower, it comprises the following steps:

[0030] a. Complete the installation of the support system 9 of the corresponding station of the prefabrication production line 10;

[0031] b. Hoist the prefabricated section N tower onto the support 11;

[0032] c. Support the inner mold 6 of the N+1 section tower on the N section tower;

[0033] d. Hoist into the reinforcement cage 7 of the N+1 section tower;

[0034] e. Support the outer form 8 of the N+1 section tower on the N section tower;

[0035] f. Adjust the verticality of the inner mold 6 and the outer mold 8;

[0036] g. Pouring the N+1 section of the tower;

[0037] h. Remove the section N tower;

[0038] i. Adjust the N+1 section tower to the support 11;

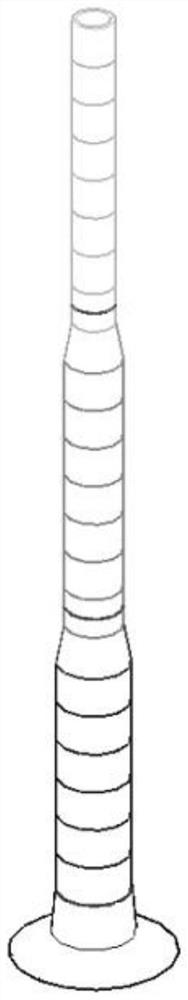

[0039] j. Repeat steps b~g to complete the preparation of all tower tubes in order from bottom to top, and obtain the following figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com