Fixing device for workpiece inner hole machining

A fixing device and inner hole technology, applied in the field of fixtures, can solve the problems of the workpiece being compressed and deformed, the inner hole size exceeds the requirements, etc., and achieves the effect of small workpiece type variable, satisfactory inner hole size, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

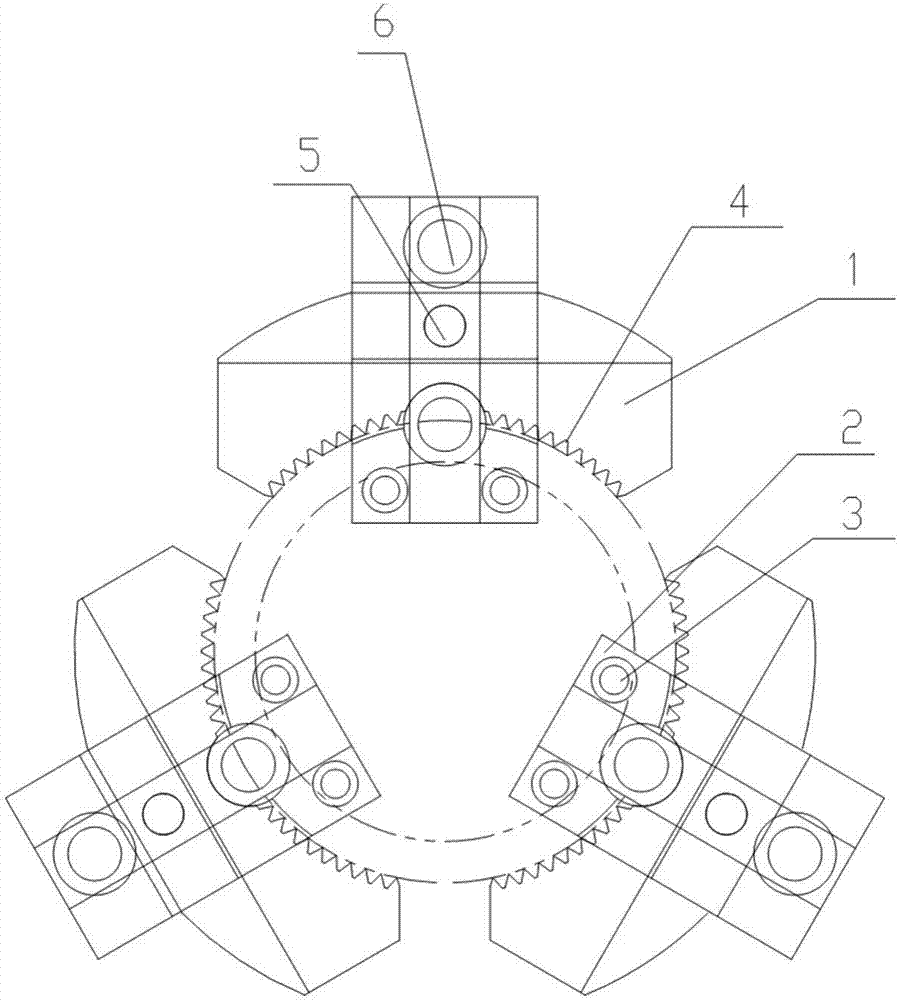

[0024] figure 1 It is a schematic top view of the structure of the workpiece inner hole processing and fixing device of the present invention. The fixing device includes three parts of the structure, and the three parts of the structure are the same in size and shape, and the three parts of the structure are independent of each other, and the three parts of the structure surround A center of a circle is set to jointly realize the fixing of the workpiece. The inner side of the fixture 4 is set as a circular arc structure, and the inner side of the three-part structure jointly forms a circular structure. The machine tool spindle drives the three-part structure to move to realize operations such as loading, clamping, and unloading of the workpiece.

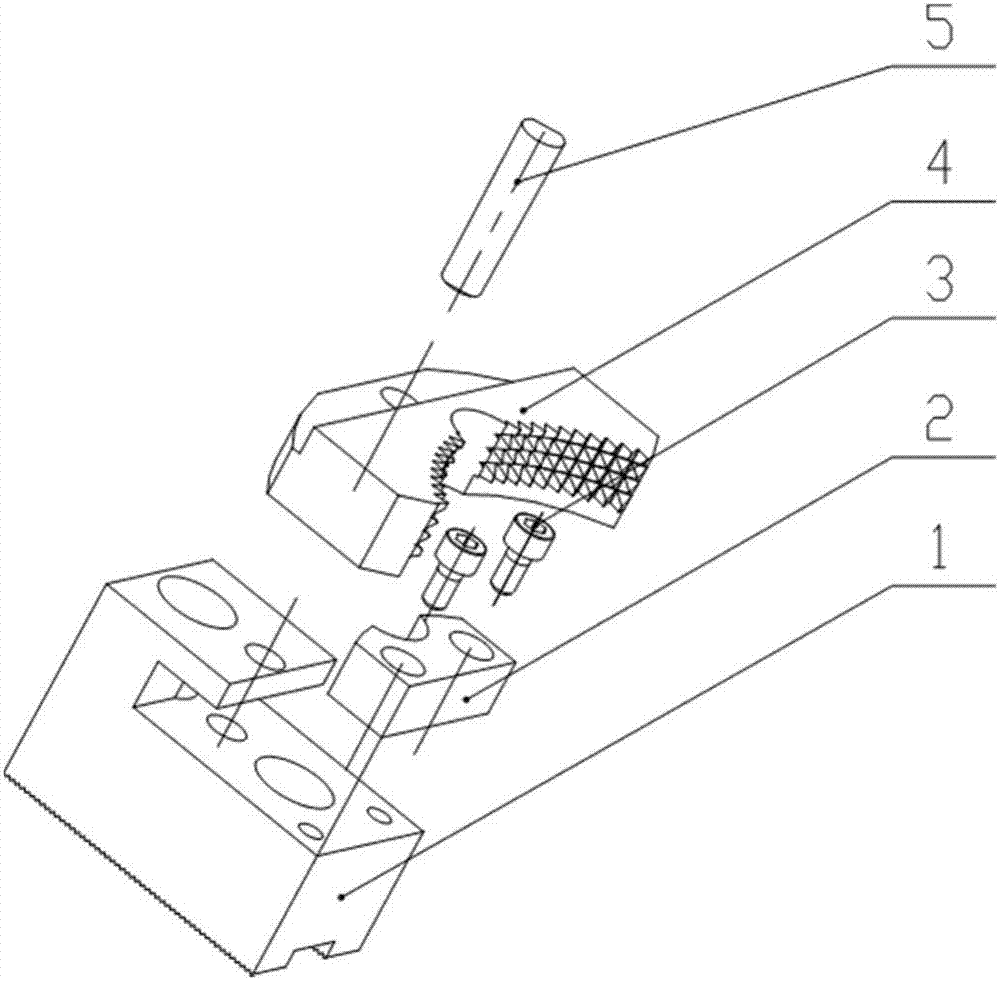

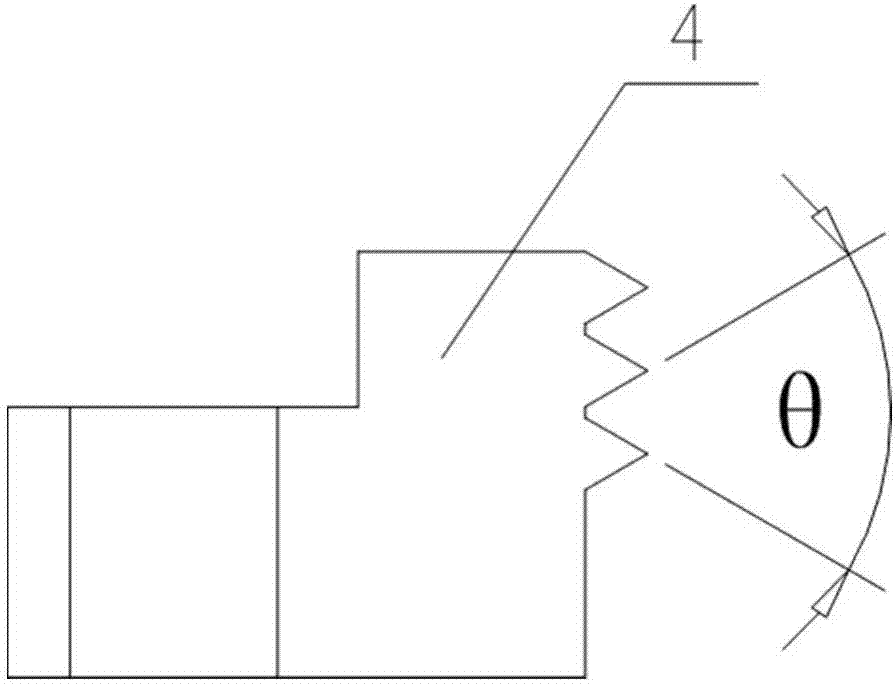

[0025] A single part of the fixing device includes a base 1, a positioning block 2, and a clamp 4, the positioning block 2 is connected to the base 1, the clamp 4 is arranged on the base 1 and connected to the base 1, the The positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com