Permanent-magnet embedded part gripper device

A gripper device and permanent magnet technology, which is applied in the field of permanent magnet insert gripper devices, can solve problems such as low automation procedures and low efficiency, and achieve the effects of avoiding industrial accidents, improving efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

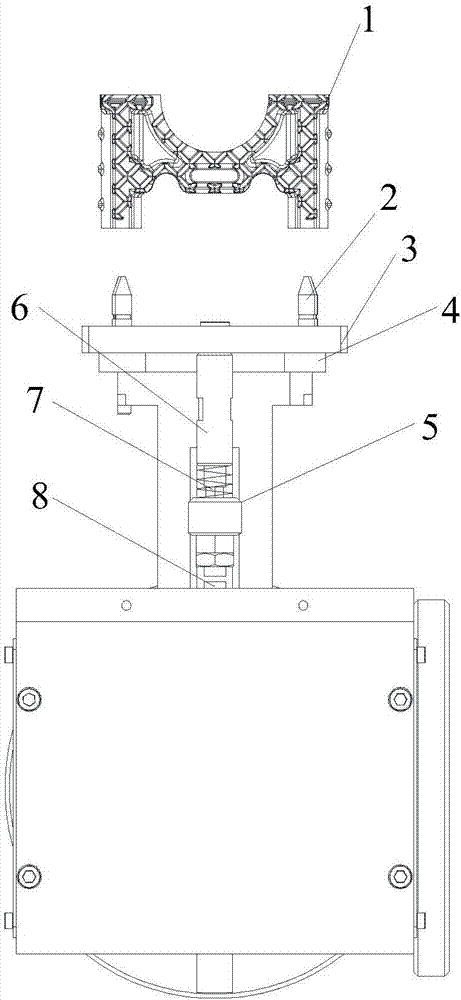

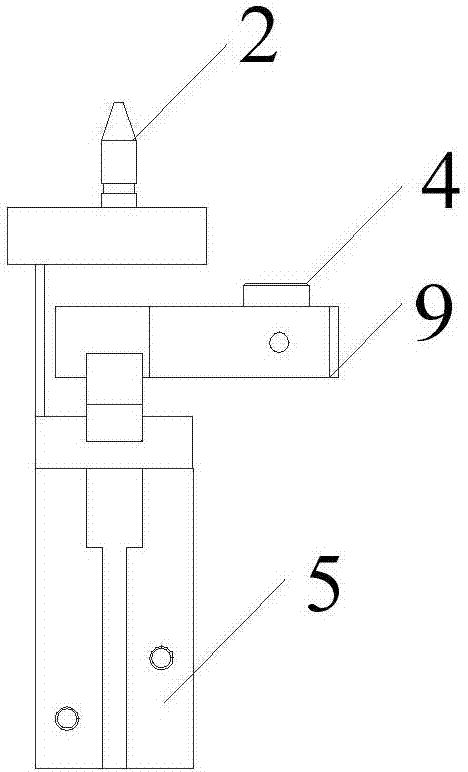

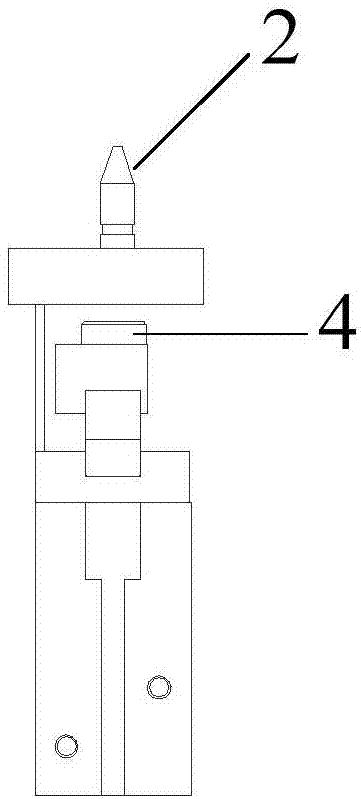

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations will now be described in detail with reference to the accompanying drawings.

[0024] like figure 1 As shown, the permanent magnet insert gripper device includes a permanent magnet 4, a rotating cylinder 5, an induction rod 6 and a positioning pin 2. The positioning pin 2 is installed on the positioning pin mounting plate 3, and the positioning pin mounting plate 3 is distributed with multiple A positioning pin 2, the positioning pin mounting plate 3 is carried on the base through the induction rod 6, the bottom end of the induction rod 6 is placed in the guide hole of the base through the spring 7, and the sensor 8 is installed on the spring 7, and the sensor 8 is connected to the base. Die-casting machine control system communication connection; a rotary cylinder 5 is also installed on the base, a magnet mounting plate 9 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com