Comprehensive fume hood for laboratory

A laboratory, fume hood technology, applied in cleaning methods and utensils, chemical instruments and methods, and smoke removal, etc., can solve the problem of lack of colorimetric card fixing device, colorimetric card sticking indiscriminately, and fragile glass instruments, etc. problems, to achieve the effect of improving experimental efficiency, clean and beautiful environment, and avoiding pollution and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be specifically described below through examples, which are only used to further illustrate the present invention, and should not be construed as limiting the scope of protection of the present invention. Technical engineers in this field can make some non-essential improvements and Adjustment.

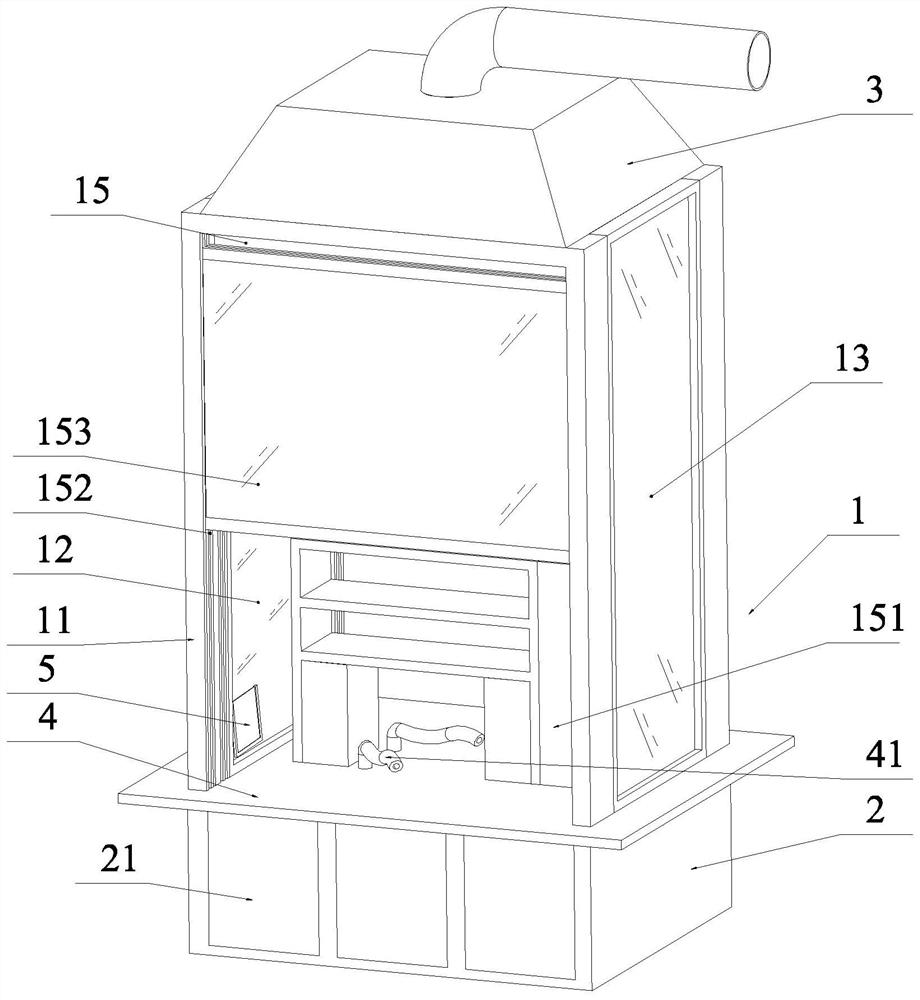

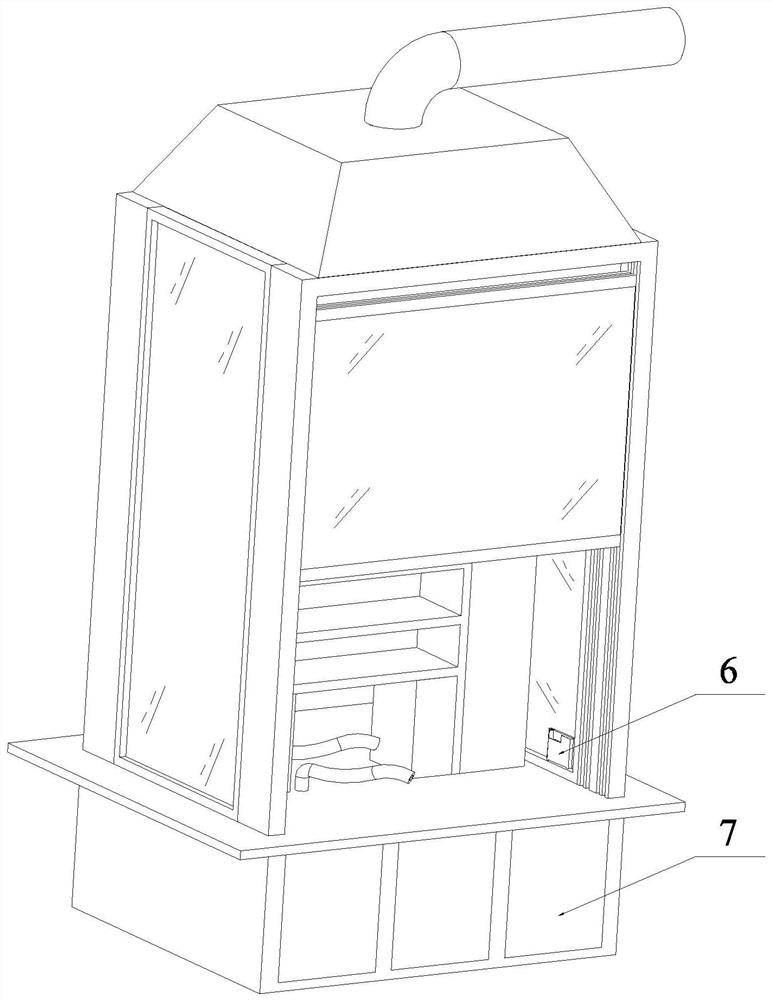

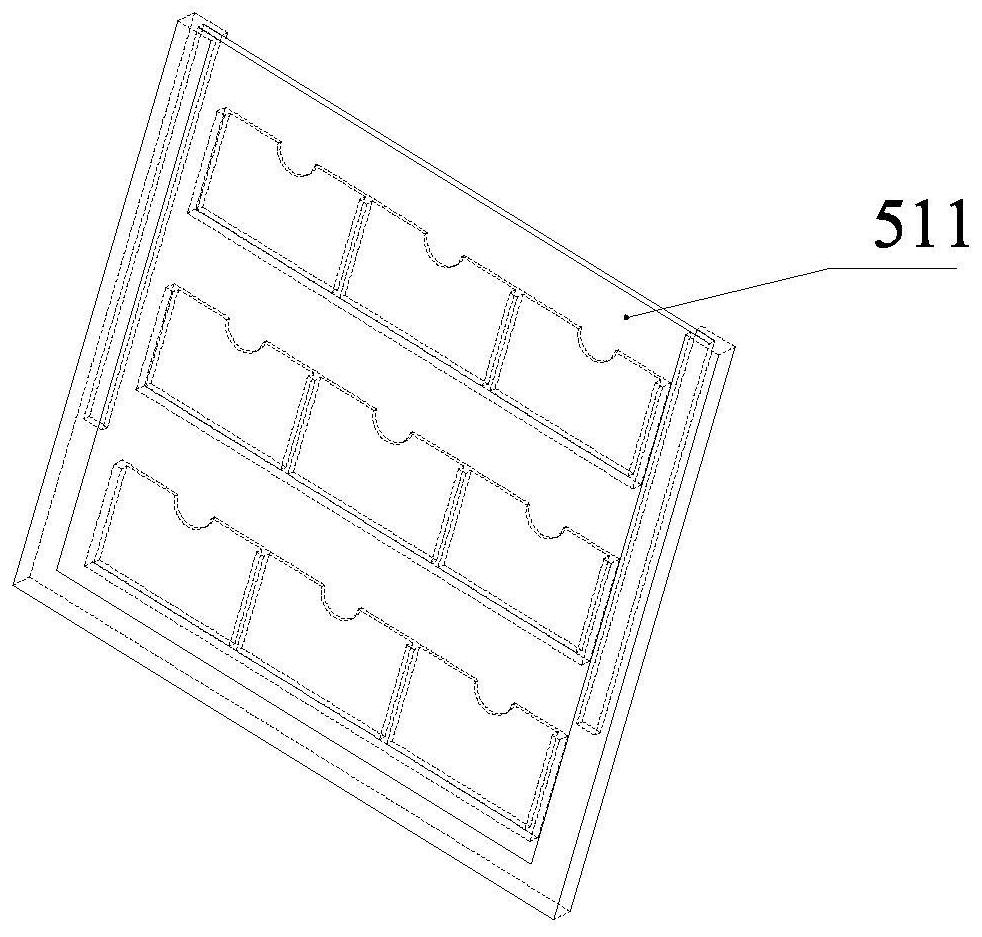

[0049] like Figure 1-2 , the specific embodiment of the present invention includes an upper cabinet 1 and a lower cabinet 2, the top of the upper cabinet 1 is provided with an exhaust hood 3 that communicates with the inner cavity of the upper cabinet, and the upper cabinet 1 The bottom surface of the cabinet body 1 is the workbench 4, and the upper cabinet body 1 includes four main frame columns 11 fixed to the four corners of the workbench, and a left transparent frame is arranged between the two main frame columns on the left side of the workbench. The light-transmitting glass plate 12 is provided between the two main frame columns on the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com