Steelmaking converter process

A steel-making converter and process technology, applied in the manufacture of converters, etc., can solve the problems affecting the recovery of converter gas and low calorific value of gas, and achieve the effects of reducing the amount of gas released, protecting the environment and prolonging the time of gas recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention will be further described below in conjunction with embodiment:

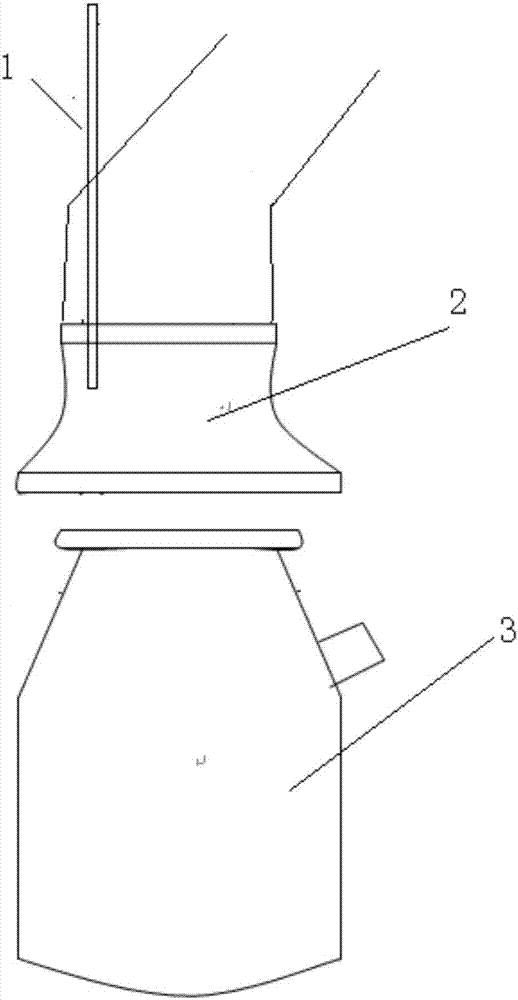

[0021] See figure 1 , is a schematic diagram of the process of reusing waste plastics in the converter of the present invention: comprising a spray gun 1, a converter hood 2 and a converter 3, the process of reusing waste plastics in the converter is to utilize the water-cooled spray gun arranged above the converter hood to smelt in the converter During the process, according to the content of CO in the flue gas, medium-pressure gas is used to spray old plastic particles into the fume hood, and the plastic particles burn at high temperature to produce CO. Technical solution: Pre-granulation of waste plastics. Requirements for plastic granules: ≥ 80% of the particle size ≤ 3mm, the material granules are transported to the high-level storage tank of the converter, and the nitrogen pressure in the spray tank is confirmed to be ≥ 0.5 MPa; with the blowing of the converter, The water-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com