A leaching material capable of adsorbing and degrading organic chlorine pollutants and its preparation method

A pollutant and organochlorine technology, applied in the field of leaching materials, can solve the problems of non-recyclable oxidized materials, complex composition, and difficulty in achieving the removal of POPs in highly polluted soils, so as to improve the removal rate of adsorption and leaching, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

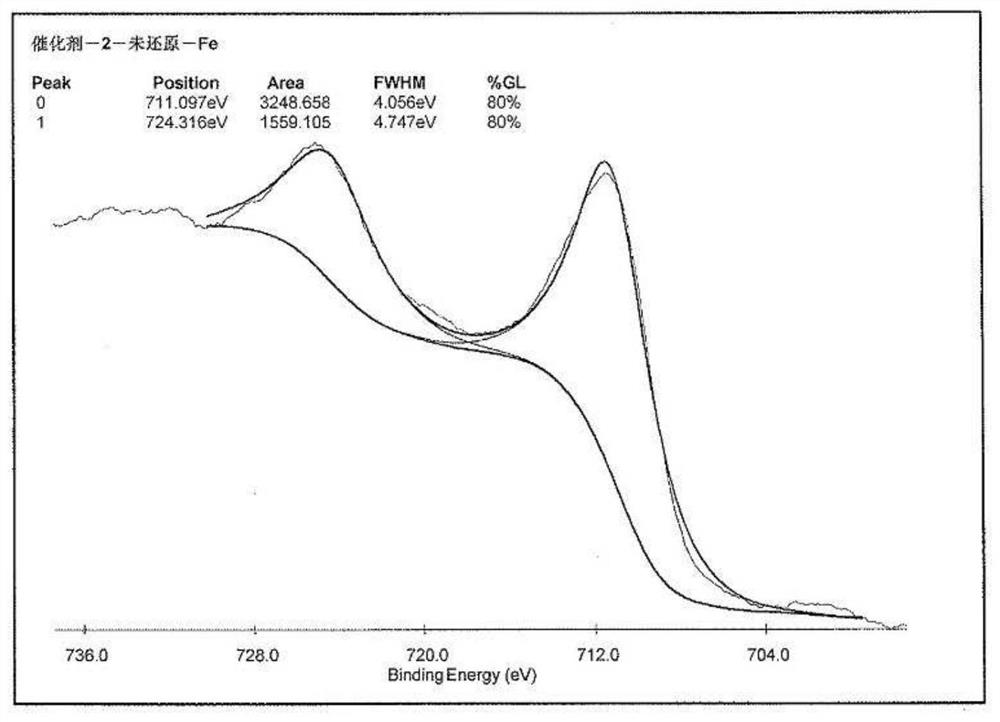

Image

Examples

Embodiment 1

[0034] The preparation method of present embodiment rinse material is as follows:

[0035] 1) Humate esterification: Slowly add glycerin and palmitic acid into a round bottom flask successively, then stir and add humic acid passed through a 200-mesh sieve in an oil bath at 150°C, and then add concentrated sulfuric acid catalyst to react for 20 hours. Afterwards, the esterified humic acid is obtained by suction filtration, washing and drying. Wherein, the volume ratio of palmitic acid and glycerol is 3; the mass ratio of palmitic acid and glycerin total volume to humic acid is 5ml / g, and the volume that the concentrated sulfuric acid catalyst adds is 2% of total reaction volume.

[0036] 2) Etherification of esterified humic acid: Add the above-mentioned esterified humic acid into a certain amount of water, react in a water bath at 50°C, and use dilute HNO 3 Adjust the pH to 5 with dilute NaOH solution, add glycerol ether mixed with acetone, react for 8 hours, and obtain ether...

Embodiment 2

[0042] The preparation method of present embodiment rinse material is as follows:

[0043] 1) Esterification of humic acid: slowly add glycerin and oleic acid into a round-bottomed flask successively, then stir and add humic acid passed through a 300-mesh sieve in an oil bath at 180°C, and then add concentrated sulfuric acid catalyst to react for 25 hours. Afterwards, the esterified humic acid is obtained by suction filtration, washing and drying. Wherein, the volume ratio of oleic acid and glycerol is 2; the mass ratio of oleic acid and glycerin total volume to humic acid is 4ml / g, and the volume that the concentrated sulfuric acid catalyst adds is 1% of total reaction volume.

[0044] 2) Etherification of esterified humic acid: Add the above-mentioned esterified humic acid into a certain amount of water, react in a water bath at 60°C, and use dilute HNO 3 Adjust the pH to 6 with dilute NaOH solution, add shrink ether mixed with acetone, react for 6 hours, filter with suctio...

Embodiment 3

[0047] The preparation method of present embodiment rinse material is as follows:

[0048] 1) Humic esterification: Slowly add glycerin and linoleic acid into a round-bottomed flask successively, then stir and add humic acid passed through a 400-mesh sieve in an oil bath at 120°C, and then add concentrated sulfuric acid catalyst to react for 28 hours. After the reaction, the esterified humic acid is obtained by suction filtration, washing and drying. Wherein, the volume ratio of linoleic acid and glycerol is 6; the mass ratio of linoleic acid and glycerin total volume to humic acid is 7ml / g, and the volume that the concentrated sulfuric acid catalyst adds is 5% of total reaction volume.

[0049] 2) Etherification of esterified humic acid: Add the above-mentioned esterified humic acid into a certain amount of water, react in a water bath at 80°C, and use dilute HNO 3 Adjust the pH to 4 with dilute NaOH solution, add shrink ether mixed with acetone, react for 9 hours, filter wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com