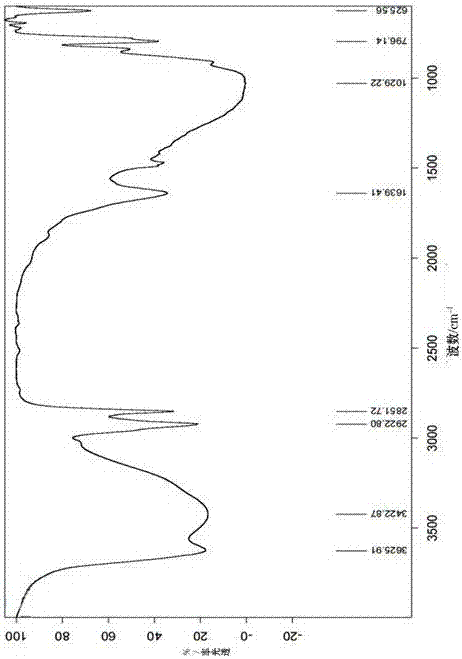

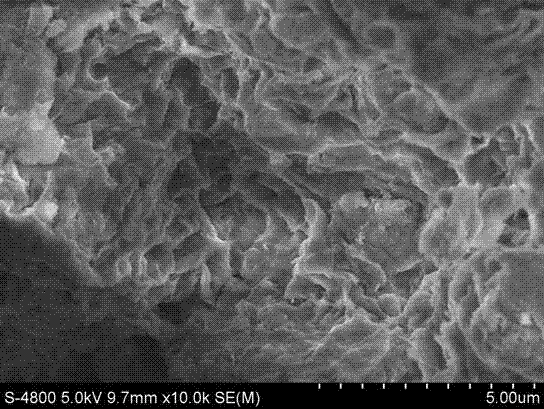

Preparation method for graphene oxide-modified attapulgite composite adsorption material

A composite adsorption material and attapulgite technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problem that the composite adsorption material of graphene oxide and attapulgite has not been reported in the literature, etc. Achieve the effect of improved operability, good adsorption performance, and developed void structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of chitosan-modified attapulgite: Add 10 g of chitosan to a mixed solution of 200 mL 10% oxalic acid and 50 mL 1% acetic acid, stir slowly and heat to 50°C to dissolve it completely. 4% pale yellow viscous sol. Take 100 mL of the sol, dilute with 100 mL of deionized water, shake at 50° C. for 1 h, slowly add 50 g of attapulgite, and continue stirring for 5 h to obtain a chitosan-modified attapulgite suspension.

[0044](2) Preparation of graphene oxide suspension: Weigh 0.10 g of graphite oxide solid into a beaker, add 500 mL of deionized water to make the concentration of graphite oxide 0.2 mg / mL, and place the beaker in an ultrasonic cleaner (40KHz, 200W) Ultrasound for 2 hours to obtain a stable graphene oxide suspension with no visible particles;

[0045] (3) Preparation of graphene oxide-attapulgite functional material: Place the above graphene oxide suspension in an ultrasonic cleaner, slowly add 4.0mL of chitosan attapulgite suspension while ultr...

Embodiment 2

[0048] (1) Preparation of cetyltrimethylammonium bromide-modified attapulgite: Add 5 g of attapulgite to 50 mL of deionized water, and stir thoroughly to obtain attapulgite suspension; adjust the temperature of attapulgite suspension to 70°C , adding 0.25 g of cetyltrimethylammonium bromide, and stirring for 3 hours to obtain a cetyltrimethylammonium bromide-modified attapulgite suspension.

[0049] (2) Preparation of graphene oxide suspension: Weigh 0.2g of graphite oxide solid into a beaker, add 500mL of deionized water to make the concentration of graphite oxide 0.4mg / mL, place the beaker in an ultrasonic cleaner (40KHz, 200W ) for 3 hours of ultrasonication to obtain a stable graphene oxide suspension with no visible particles;

[0050] (3) Preparation of graphene oxide-attapulgite functional material: put the above graphene oxide suspension in an ultrasonic cleaner, and slowly add 20.0 mL of the above cetyltrimethylammonium bromide modified Attapulgite suspension, fully ...

Embodiment 3

[0053] (1) Preparation of tetrabutylammonium bromide-modified attapulgite: add 20 g of attapulgite to 200 mL of deionized water, and shake at a constant temperature (150 r / min) at 60 °C for 2 h to obtain attapulgite suspension; then add 0.83 g tetrabutylammonium bromide, and stirred for 2 hours to obtain tetrabutylammonium bromide-modified attapulgite suspension.

[0054] (2) Preparation of graphene oxide suspension: Weigh 0.15g of graphite oxide solid into a beaker, add 500mL of deionized water to make the concentration of graphite oxide 0.3mg / mL, place the beaker in an ultrasonic cleaner (40KHz, 200W ) for 2 hours of ultrasonication to obtain a stable graphene oxide suspension with no visible particles;

[0055] (3) Preparation of graphene oxide-attapulgite functional material material: put the above graphene oxide suspension in an ultrasonic cleaner, and slowly add 5.0 mL of tetrabutylammonium bromide-modified attapulgite suspension while ultrasonicating, Stir fully (300 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com