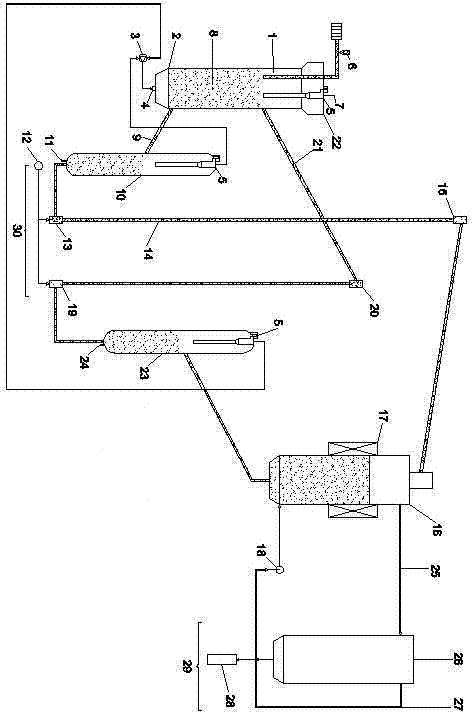

High-concentration VOC gas purification and recovery apparatus and high-concentration VOC gas purification and recovery method

A gas purification and recovery device technology, which is applied to chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of easy-to-ignite organic solvents in the bed, and fire in the fixed-bed bed, so as to avoid gas blow-by, increase material The effect of sealing function and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] (1) Ethyl acetate organic waste gas in the waste gas, the treatment capacity is 350m 3 / h, ethyl acetate content 10g / m 3 ;(2) Using fluidized bed adsorption technology, the organic waste gas of ethyl acetate is adsorbed by 40 mesh coconut shell activated carbon adsorbent at 40°C; (3) The tower height of the fluidized bed adsorption tower is 3000mm; (4) The desorption tower desorbs and regenerates the activated carbon adsorbent with nitrogen at 100°C. The desorbed activated carbon adsorbent can re-enter the adsorption tower for adsorption. The optimal temperature for desorption is 100°C; (5) Mixing after desorption The gas is condensed in the condensation tower, the organic solvent is condensed and liquefied to be recycled, and the nitrogen gas re-enters the desorption tower for desorption and recycling.

[0041] In the adsorption tower, the concentration of ethyl acetate organic waste gas is from 10g / m 3 down to 100mg / m 3 Below, it can meet the national exhaust gas e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com