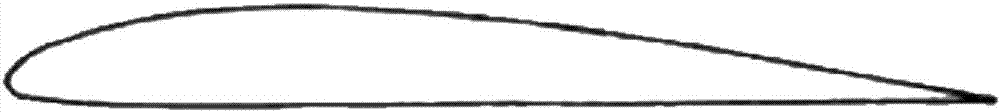

Step wing used for ejection type glider model

A glider and catapult technology, applied in toy planes, entertainment, toys, etc., can solve the problems of wasting time, difficult to master precision, and laborious, and achieve the effect of reducing wing weight, simple production, and precise processing and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 2-6 As shown, a wing 1 and an empennage 3 are installed on the fuselage 2, and a through hole (not shown) and a hook for ejection (not shown in the figure) for adjusting the center of gravity of the catapult glider model are formed on the front portion of the fuselage. show). The wing adopts three-section installation, and the wing is composed of the middle section 1-2 of the wing and 2 wing tips 1-1, such as figure 2 As shown, the middle section of the wing is horizontally installed on the fuselage through a mortise and tenon mechanism, which makes the connection between the wing and the fuselage very simple and precise, and the manual connection speed only takes 20 seconds; the two wingtips are respectively bonded It is fixed at both ends of the middle section of the wing, and the dihedral angle of the wingtip is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com