Steel roller and dial combined round baler

A round baler and combined technology, applied in the field of agricultural machinery, can solve problems such as blockage of steel roller round balers, failure to pick up and bundle normally, difficulty in forming rotating grass cores, etc. The effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

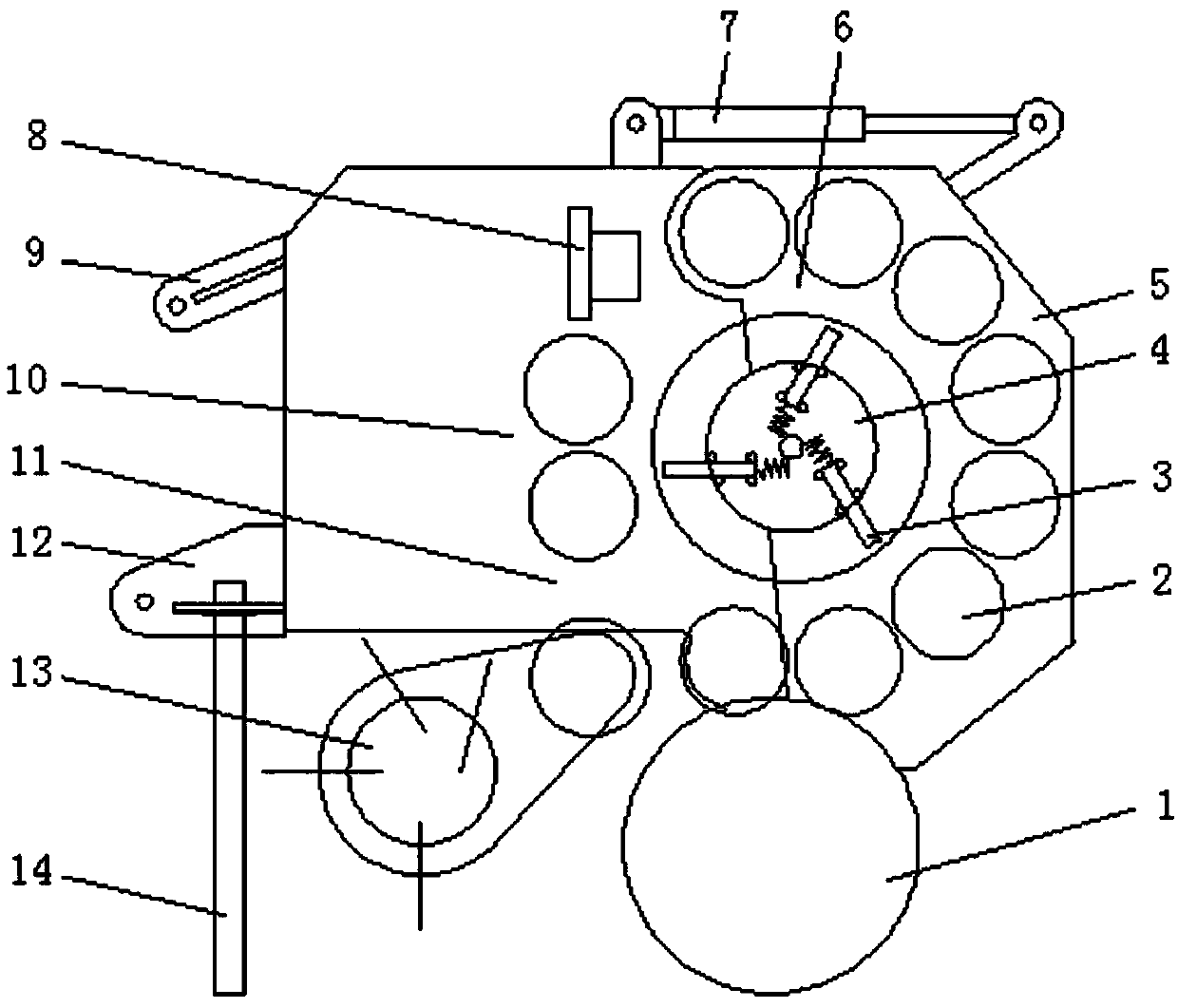

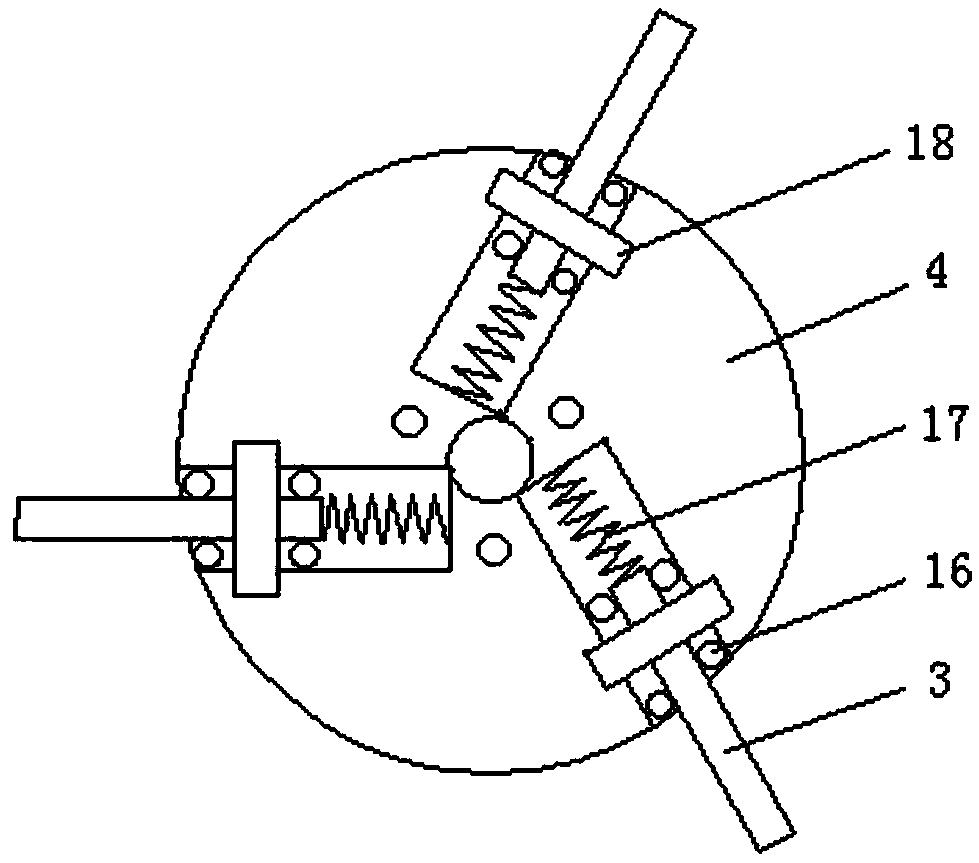

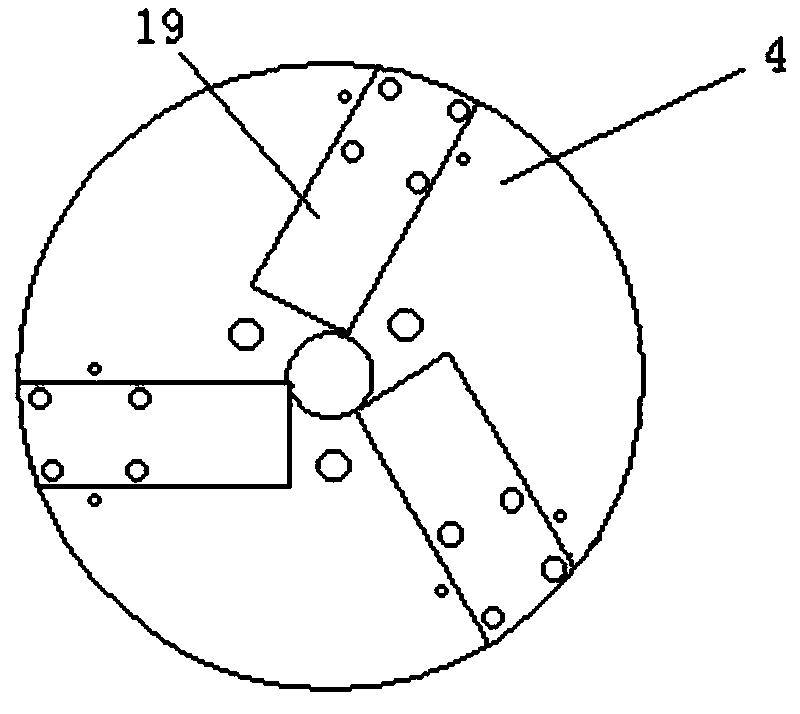

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The pick-up mechanism 13 is fitted at the front and lower part of the steel roller and dial combined round baler, the steel roller 2 is fitted in the bale chamber 6 along the circumference; the dial is fitted in the center of the side wall of the bale chamber 6 Wherein, the left dial 4 is fitted in the center of the left wall of the volume chamber 6 and on the rear body 5, the left dial 4 is a disc with three grooves 19, and the grooves 19 of the left dial 4 The dial finger 3, spring 17, and guide wheel 16 are installed inside. The dial finger 3 is a flat bar-shaped steel member whose upper plane is inclined by 3° and the two sides are inclined by 5°. The maximum length of the dial finger 3 is limited by the limit guide plate 18. , the guide wheel 16 is a nylon sleeve with a 5° inclination on both sides, the left dial 4 is rotatably sleeved on the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com