Silver paste preparation apparatus for LED packaging

A kind of LED encapsulation and airtight technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of low safety and inability to carry out multi-stage stirring preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

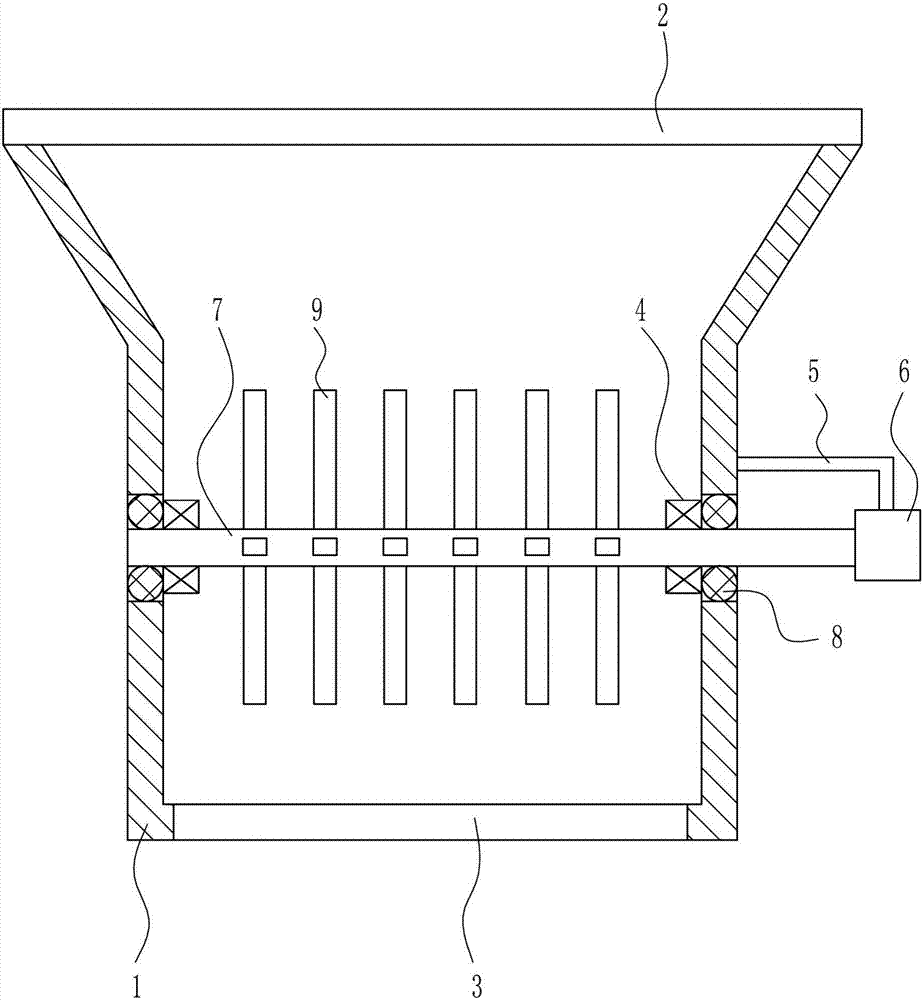

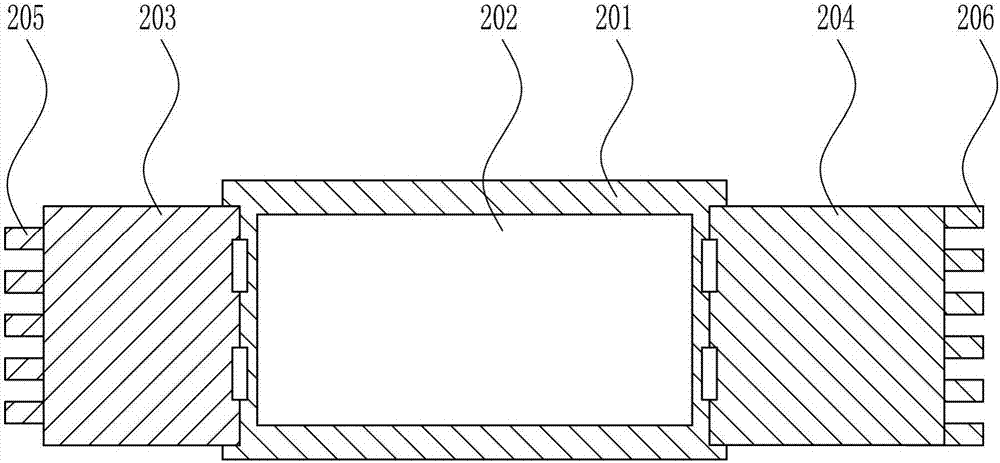

[0031] A kind of closed silver glue preparation equipment for LED encapsulation, such as Figure 1-5As shown, it includes a preparation box 1, a cap tight mechanism 2, a switch mechanism 3, a first bearing seat 4, a pole 5, a motor 6, a first rotating rod 7, a first sealing ring 8 and a first stirring rod 9, and the preparation The top of the box 1 is provided with a cover tightening mechanism 2, the bottom of the preparation box 1 is provided with a switch mechanism 3, and the inner side of the preparation box 1 is symmetrically connected with a first bearing seat 4, and the first bearing seat 4 is connected with a first rotating rod 7. Rotating rod 7 passes through the first bearing seat 4 on the right side, and the upper part of the right side of the preparation box 1 is connected with a pole 5, and the bottom end of the pole 5 is equipped with a motor 6, and the output shaft of the motor 6 is connected with the first rotating rod 7. The first stirring rod 9 is evenly conne...

Embodiment 2

[0033] A kind of closed silver glue preparation equipment for LED encapsulation, such as Figure 1-5 As shown, it includes a preparation box 1, a cap tight mechanism 2, a switch mechanism 3, a first bearing seat 4, a pole 5, a motor 6, a first rotating rod 7, a first sealing ring 8 and a first stirring rod 9, and the preparation The top of the box 1 is provided with a cover tightening mechanism 2, the bottom of the preparation box 1 is provided with a switch mechanism 3, and the inner side of the preparation box 1 is symmetrically connected with a first bearing seat 4, and the first bearing seat 4 is connected with a first rotating rod 7. Rotating rod 7 passes through the first bearing seat 4 on the right side, and the upper part of the right side of the preparation box 1 is connected with a pole 5, and the bottom end of the pole 5 is equipped with a motor 6, and the output shaft of the motor 6 is connected with the first rotating rod 7. The first stirring rod 9 is evenly conn...

Embodiment 3

[0036] A kind of closed silver glue preparation equipment for LED encapsulation, such as Figure 1-5 As shown, it includes a preparation box 1, a cap tight mechanism 2, a switch mechanism 3, a first bearing seat 4, a pole 5, a motor 6, a first rotating rod 7, a first sealing ring 8 and a first stirring rod 9, and the preparation The top of the box 1 is provided with a cover tightening mechanism 2, the bottom of the preparation box 1 is provided with a switch mechanism 3, and the inner side of the preparation box 1 is symmetrically connected with a first bearing seat 4, and the first bearing seat 4 is connected with a first rotating rod 7. Rotating rod 7 passes through the first bearing seat 4 on the right side, and the upper part of the right side of the preparation box 1 is connected with a pole 5, and the bottom end of the pole 5 is equipped with a motor 6, and the output shaft of the motor 6 is connected with the first rotating rod 7. The first stirring rod 9 is evenly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com