High-temperature-resistant electrical capacitance tomography sensor

A technology of electrical capacitance tomography and sensors, which is applied in the direction of material capacitance, etc., can solve the problems such as the difficulty of fixing the measurement electrode array and the difficulty of increasing the fluidization uniformity of the furnace bed material, and achieve the effect of broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

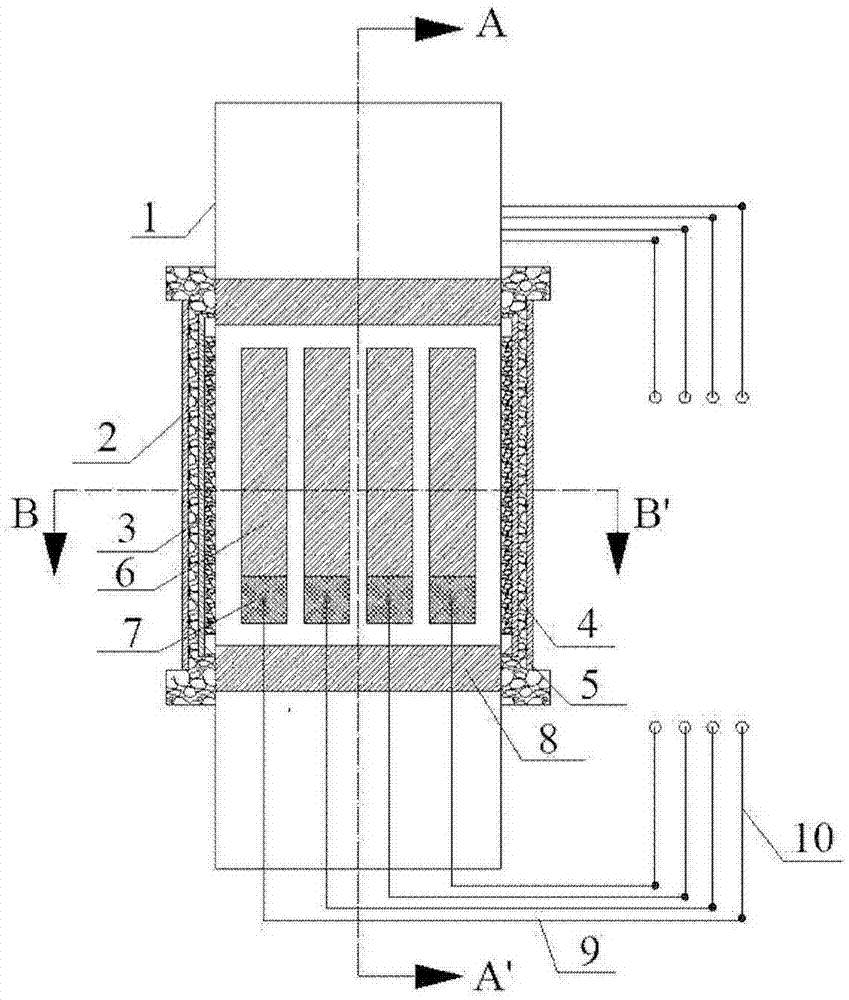

[0029] The present invention designs a high-temperature-resistant ECT sensor, which can be used normally in a high-temperature environment from room temperature to 600° C., and realizes two-dimensional visualization of multiphase flow distribution in this temperature range.

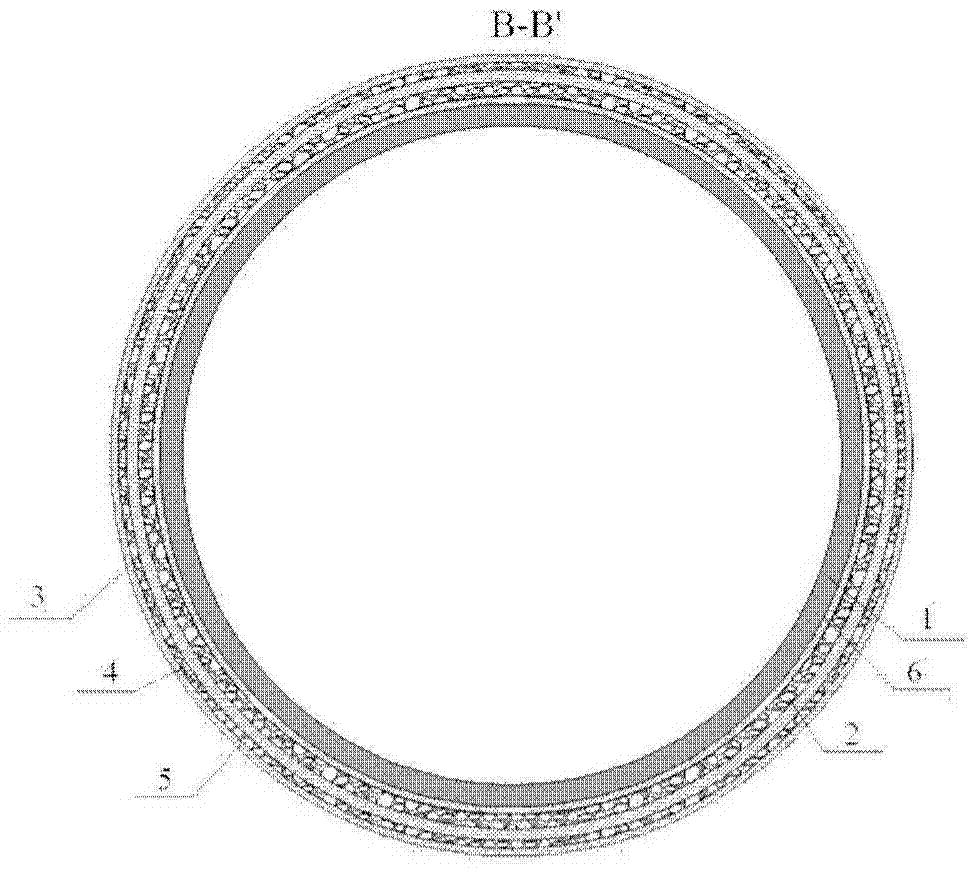

[0030] More specifically, the present invention provides an ECT sensor applied in a high temperature environment from room temperature to 600°C. High-temperature insulation isolation layer, 600°C-resistant shaft-end shielding electrode connection layer, 600°C-resistant fixed layer, 600°C-resistant shield cover, 600°C-resistant high-temperature section signal transmission line and the application at room temperature Normal temperature section signal transmission line;

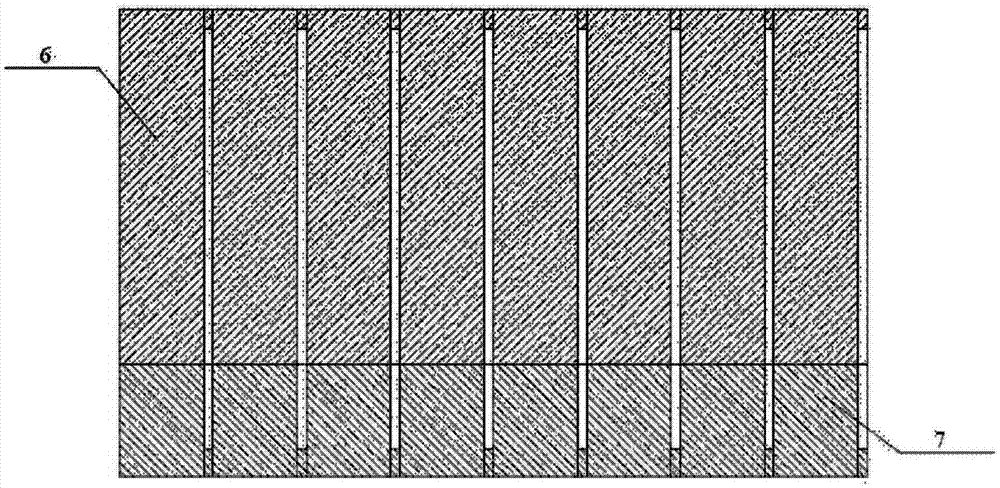

[0031]The 600°C-resistant array distributed electrodes are N electrode sheets of the same size and composed of measuring ends and fixed ends, and the value of N is an integer ranging from 8 to 16; the 600°C-resistant high-temperature segmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com