Optical fiber humidity sensor based on molybdenum diselenide and preparation method thereof

A technology of humidity sensor and molybdenum diselenide, which is applied in instruments, scientific instruments, and material analysis through optical means, can solve the problems of insufficient precision, complex structure, and difficult preparation, and achieve low production cost and linear correlation High, anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] Figure 7 A method for preparing an optical fiber humidity sensor based on molybdenum diselenide is shown in Embodiment 2 of the present invention, comprising the steps of:

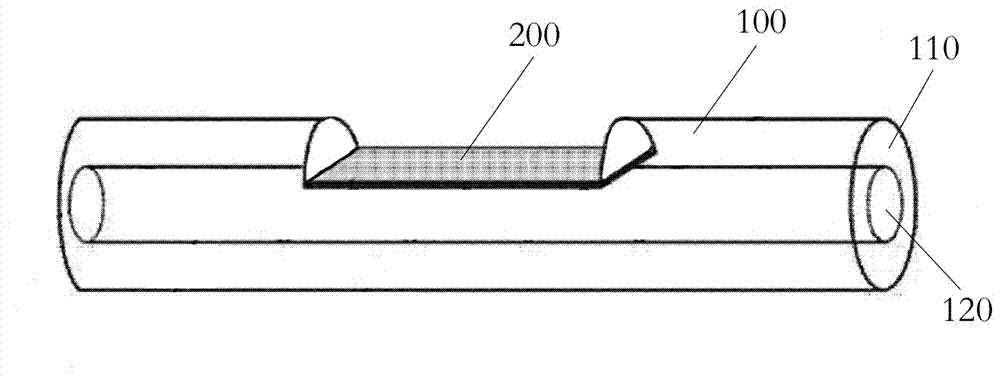

[0046] S1. Preparation of side-polished single-mode optical fiber: by polishing, a part of the cladding 110 and the fiber core 120 of the optical fiber are removed, and a flat area of a certain length is formed on the surface of the optical fiber, that is, the polished surface 300; the side-polished The thickness of the polished surface 300 of the optical fiber 100 is 67 μm (a part of the fiber core 120 is also polished at this time), and the length of the polished surface 300 is 16 mm;

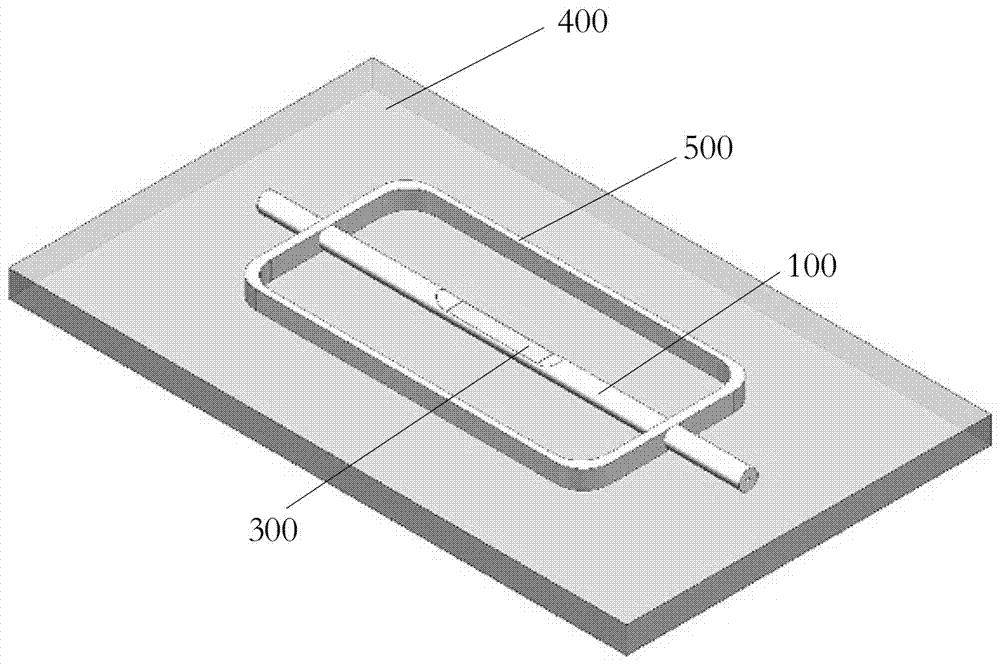

[0047] S2. Depositing a molybdenum diselenide film layer 200: as figure 2 , use UV glue to fix the side polishing part on the glass slide 400, with the polishing surface 300 facing up, and then use UV glue to make a groove 500 around the polishing surface 300, the size of the groove 500 is 2×0.5×0.1 cm 3 , d...

Embodiment 3

[0050] The steps of embodiment 3 are basically the same as those of embodiment 2, both of which use single-mode optical fiber as the preparation method of side-polished optical fiber 100, the difference lies in:

[0051] The polishing surface 300 has a thickness of 60 μm and a length of 15 mm;

[0052] Use UV glue to make a groove 500 around the polishing surface 300 with a size of 4.5×2×0.5 cm 3 ;

[0053] The molybdenum diselenide dispersion concentration is 10mg / ml;

[0054] The molybdenum diselenide film layer 200 has a thickness of 496nm.

Embodiment 4

[0056] A kind of preparation method based on optical fiber humidity sensor, comprises the steps:

[0057] S1. Preparation of side-polished multimode optical fiber: by polishing, a part of the cladding 110 and the fiber core 120 of the optical fiber are removed, and a flat area of a certain length is formed on the surface of the optical fiber, that is, the polished surface 300; the polished surface 300 and the optical fiber The distance between the fiber core 120 is 1.5 μm, and the length of the polishing surface 300 is 17 mm;

[0058] S2. Depositing the molybdenum diselenide film layer 200: use UV glue to fix the side polishing part on the glass slide 400, with the polishing surface 300 facing up, and then use UV glue to make a groove 500 around the polishing surface 300, The slot size is 4.5×2×0.5 cm 3 , drop the molybdenum diselenide dispersion liquid into the tank, place it at room temperature, wait until the water and alcohol evaporate naturally, and form a molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com