Novel self-air-supply explosion-proof gas distribution cabinet

A gas distribution cabinet and self-supply technology, which is applied to the treatment of combustion products, combustion methods, and removal of solid residues, etc., to achieve the effects of low failure rate, easy manufacture, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

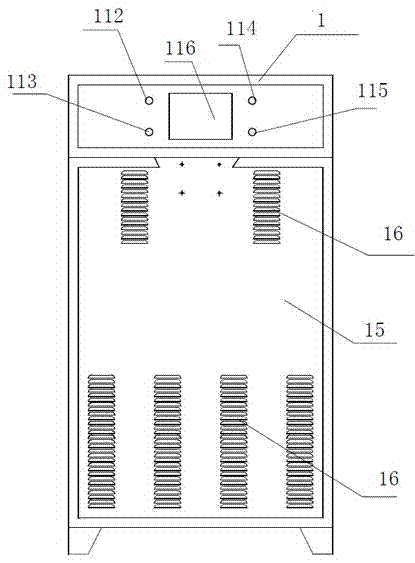

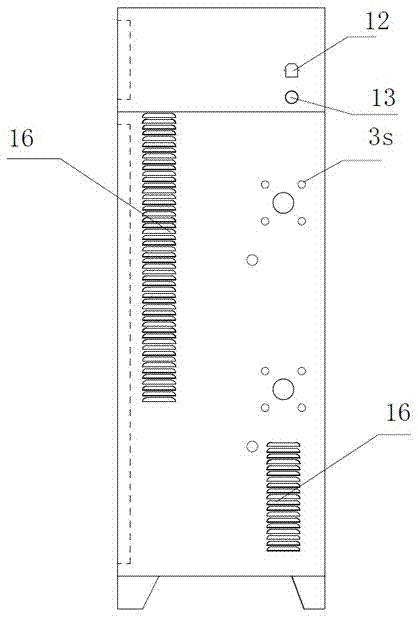

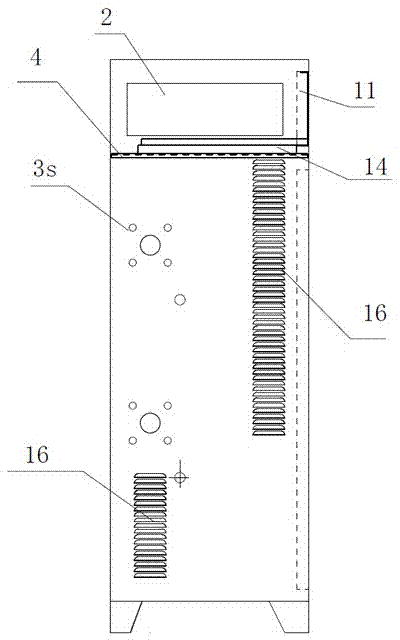

[0023] Such as Figure 1-4 As shown, a new self-supplied wind explosion-proof gas distribution cabinet includes a cabinet body 1, a control mechanism 2 and a gas distribution mechanism 3. The upper part of the cabinet body 1 is provided with a drawer 11, and the control mechanism 2 is installed in the drawer 11. , the drawer 11 is provided with a start button 112, a stop button 113, a power indicator light 114, and an alarm indicator light 115, and the side of the cabinet body 1 is provided with a power line 12 and a bus 13, and the gas distribution mechanism 3 comprises air main pipe 3a, air branch pipe one 3b, air branch pipe two 3c, air branch pipe three 3d, air branch pipe four 3e, acetylene main pipe 3f, acetylene branch pipe one 3g, acetylene branch pipe two 3h, acetylene branch pipe three 3j, acetylene branch pipe four 3k, Pulse generator one 3m, pulse generator two 3n, pulse generator three 3p, pulse generator four 3q, air branch one 3b, air branch two 3c, air branch t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com