Prefabricated staircase connection method

A technology for stairs and connecting nodes, which is applied in the direction of stairs, ladder-like structures, building structures, etc., can solve the problems of construction progress being stuck in the construction of stairs, the impact of prefabricated building efficiency, and inconvenient cast-in-place work, etc., to reduce engineering costs. Cost and labor, simple and fast construction measures, and the effect of simplifying wet working procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

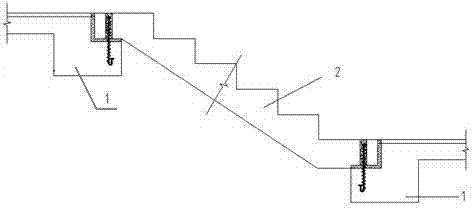

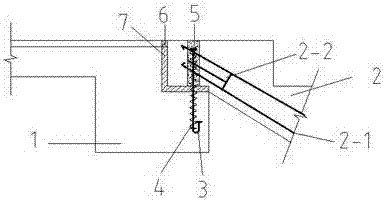

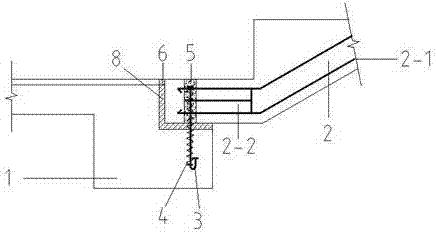

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the content of the present invention will be further elaborated below in conjunction with the accompanying drawings of the present invention.

[0023] A prefabricated staircase connection node, including floor platform beam 1, stairs 2, reserved steel bars 3, reserved spiral bars 4, concrete grouting material 5, mortar 6, polyphenylene filled and cement mortar leveling layer 7, linoleum and cement mortar leveling Floor 8; the upper and lower ends of the staircase 2 are placed on the floor platform beam 1, and are connected to the floor platform beam 1 through the reserved steel bar 3, the reserved steel bar 3 is covered with the reserved spiral bar 4, and the reserved spiral bar 4 can be Improve the brittleness of component failure, play the role of constraining the concrete in the core, so as to improve the bearing capacity of the component; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com