Bridge deck transverse slope regulating structure and paving method

A technology for structure adjustment and bridge deck pavement, which is applied in bridge construction, bridges, bridge parts, etc., can solve the problems of cushion layer dead load increase, dead load partial distribution effect, etc., so as to reduce the design size and make the structure method reasonable and ingenious , Obvious effect of economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with specific embodiments.

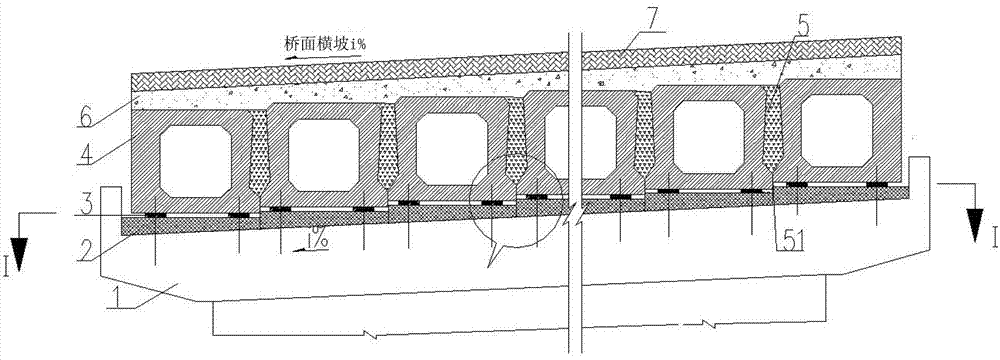

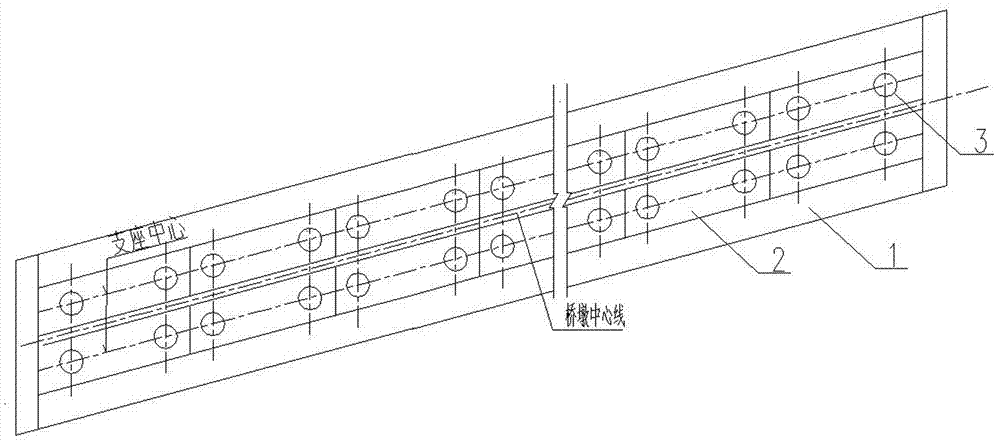

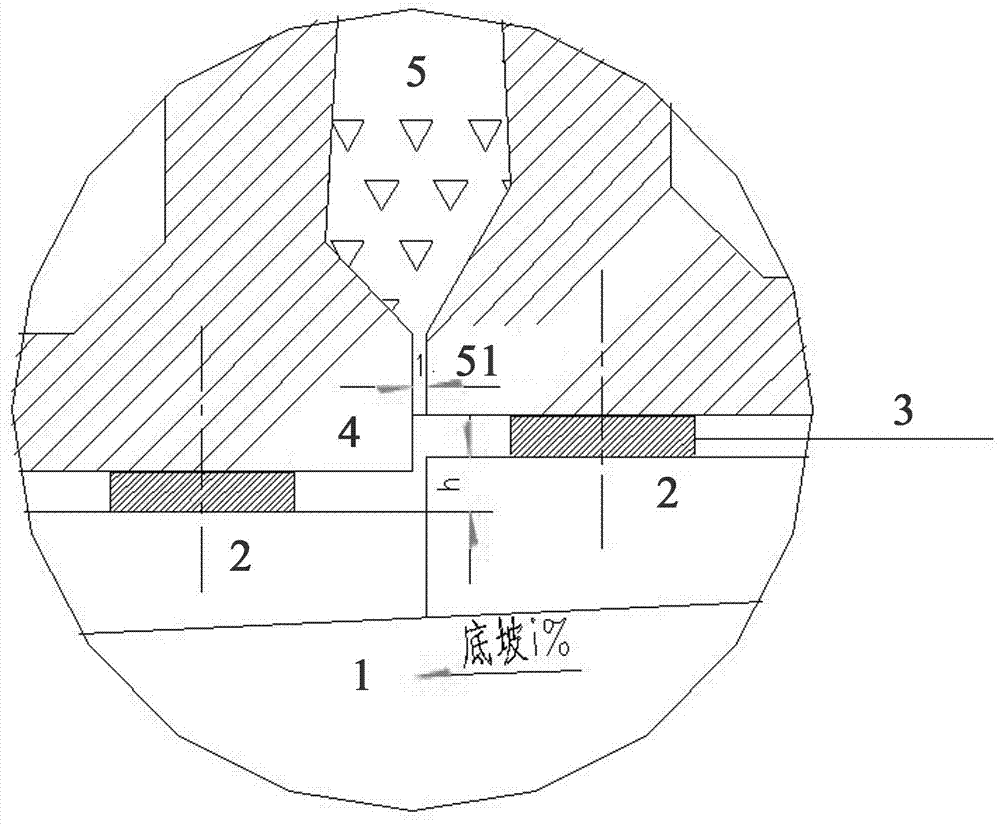

[0025] As shown in the figure: a bridge deck cross-slope adjustment structure, which includes a cover beam 1, a pad stone layer 2, a support 3, a prefabricated beam slab 4, hinge joints 5, and a bridge deck pavement layer 6 arranged on the bridge pier and the asphalt concrete layer 7, the pad stone layer 2 is arranged on the top of the cap beam 1, the pad stone layer 2 is stepped along the bridge deck transverse slope direction, and each step of the pad stone layer 2 corresponding to the top of each pier is provided with There are two supports 3 whose top and bottom surfaces are kept horizontal and have the same thickness, each pair of supports 3 is supported on both sides of the bottom surface of one end of the prefabricated beam slab 4, and each pair of supports 3 is arranged symmetrically along the width direction of the prefabricated beam slab 4 , hinge joints 5 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com