Production technology of hot-dip galvanized steel strip for home appliance plate

A production process, hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of inability to produce product quality of home appliance board products, unable to meet the needs of home appliances, poor product performance, etc. Achieve the effect of improving product quality, process optimization, and product added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

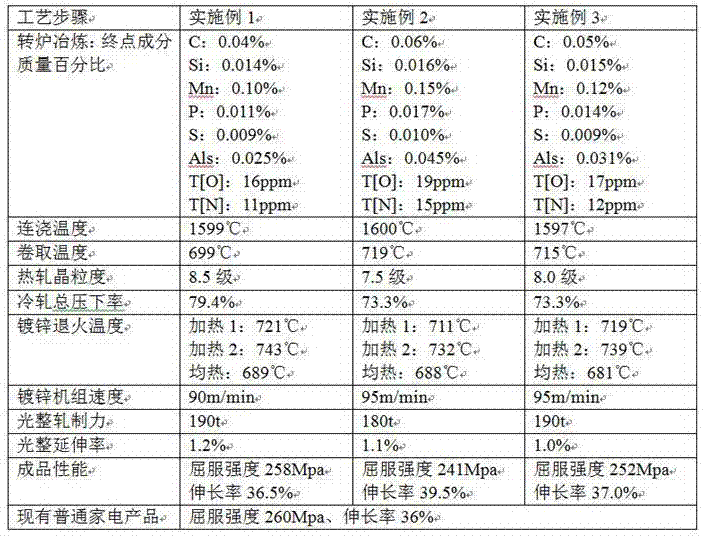

[0021] The present invention will be further described below through embodiment.

[0022] A production process of hot-dip galvanized steel strip for home appliance panels. The process includes: raw material uncoiling → narrow lap welding machine → inlet looper → alkali washing and degreasing → annealing furnace → furnace nose → zinc pot → air knife → cooling tower → Skin pass machine→tension straightening machine→passivation drying→export looper→oiler→export shear→coiler; its special features are:

[0023] ① Alkali washing and degreasing process; replace the solid degreasing agent with a liquid degreasing agent to improve the degreasing ability of the alkali washing equipment; the brushing section of the alkali washing and degreasing process, the concentration of the liquid degreasing agent is 9 ~ 11g / L; the electrolysis section of the alkaline washing and degreasing process, The concentration of liquid degreasing agent is 17~25g / L;

[0024] ②Annealing furnace process; the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com