Efficient biogas slurry fertilizer and preparation method thereof

A biogas slurry and fertilizer technology, applied in the field of agricultural waste resource recycling, can solve the problems of affecting stability and application effect, inhibiting crop growth, and not considering the combination of different forms of nitrogen, achieving good stability and application effect, realizing The effect of comprehensive utilization of resources and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

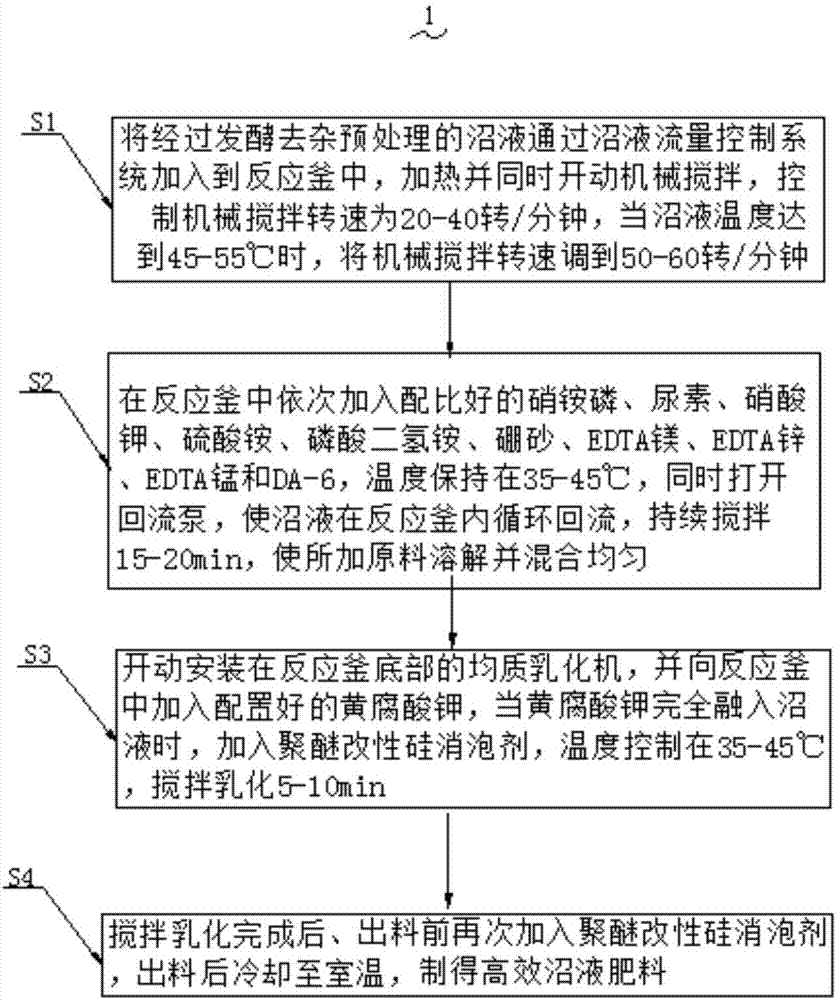

[0058] A method for preparing high-efficiency biogas slurry fertilizer, characterized in that: comprising the following steps,

[0059] S1: Add the pretreated biogas slurry through the biogas slurry flow control system into the reactor, heat and start mechanical stirring at the same time, control the mechanical stirring speed to 20-40 rpm, when the biogas slurry temperature reaches 45- At 55°C, adjust the mechanical stirring speed to 50-60 rpm;

[0060] S2: Add the proportioned ammonium nitrate phosphorus, urea, potassium nitrate, ammonium sulfate, ammonium dihydrogen phosphate, borax, EDTA magnesium, EDTA zinc, EDTA manganese and DA-6 in sequence, and keep the temperature at 35-45 ℃, turn on the reflux pump at the same time, make the biogas slurry circulate and reflux in the reactor, and keep stirring for 15-20min to dissolve and mix the added raw materials evenly;

[0061] S3: Start the homogeneous emulsifier installed at the bottom of the reactor, and add the configured po...

Embodiment 1

[0073] 1. Biogas slurry pretreatment:

[0074] 1) Separating the anaerobic fermentation substrate of fruit and vegetable waste that has normally produced gas for 1-3 months through a solid-liquid separation device, and the separated biogas slurry water-insoluble matter is less than 70g / L;

[0075] 2) The biogas slurry separated from the solid-liquid separation device is injected into the biogas slurry aeration tank through the pipeline for aerated fermentation, so that the pH value of the biogas slurry after aeration is between 8.0 and 9.4;

[0076] 3) The biogas slurry after aeration is left to settle for 2-5 days, and the sediment is released from the bottom of the aeration tank.

[0077] 2. Nutrition deployment:

[0078] 1) Add the biogas slurry that has been pretreated by fermentation to remove impurities into the reactor through the biogas slurry flow control system, heat and start mechanical stirring at the same time, control the mechanical stirring speed to 20-40 rpm, ...

Embodiment 2

[0093] Processing step is identical with embodiment 1, and difference is that each component consumption weight percent is as follows:

[0094] Biogas slurry: 36.36%;

[0095] Phosphorous ammonium nitrate: 10.7%;

[0096] Urea: 24.62%;

[0097] Potassium nitrate: 9.67%;

[0099] Ammonium dihydrogen phosphate: 5.86%;

[0100] Trace elements: 2.69%;

[0101] DA-6: 0.1%;

[0102] Potassium Fulvic Acid: 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com