Method for treating and reusing fracturing backflow fluid of shale gas

A flowback fluid and air pressure technology, applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Sulfur, saving equipment investment cost and improving the effect of recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

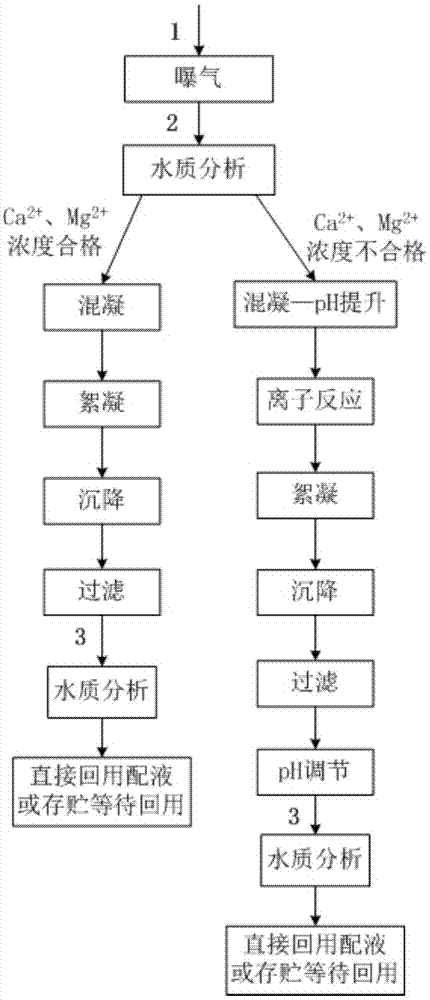

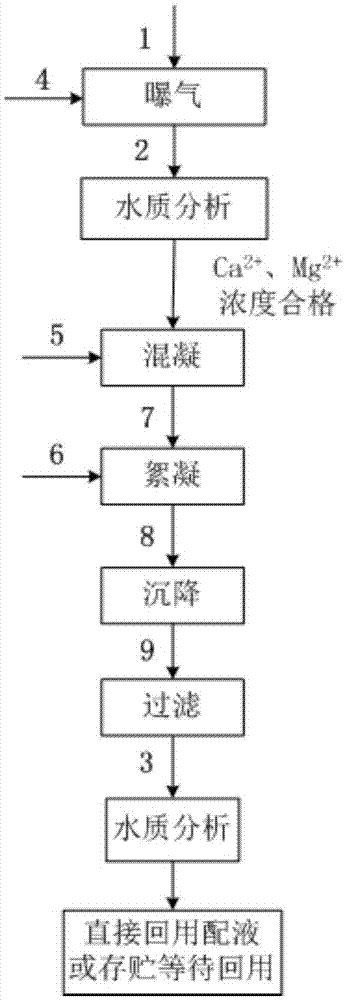

[0073] This embodiment provides a method for treating and reusing shale gas fracturing flowback fluid when the total hardness value of shale gas fracturing flowback fluid is qualified, see figure 2 , the processing reuse method includes the following steps:

[0074] Step 101: After the initial shale gas fracturing flowback fluid 1 flowed back from the wellhead on the 5th day after the fracturing operation of a certain shale gas well is subjected to gas-liquid separation, use a floating pump impeller surface aerator (theoretical The power efficiency is 2.6~2.8kg O 2 / kW·h) to blow air 4 into it, so that the Fe in the initial shale gas fracturing flowback fluid 1 2+ Converted to Fe(OH) 3 , to obtain the oxidized shale gas fracturing flowback fluid 2.

[0075] Step 102, using the hydraulic fracturing analysis component of the HACH portable water quality analysis laboratory to detect the water quality of the oxidized post-shale gas fracturing flowback fluid 2, and contact the ...

Embodiment 2

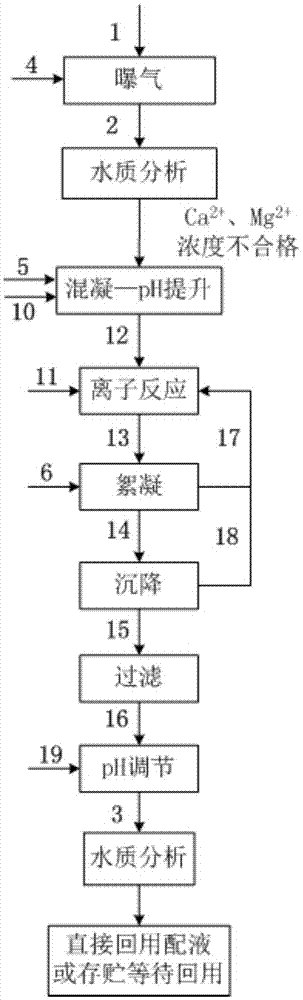

[0085] This embodiment provides a method for treating and recycling shale gas fracturing flowback fluid when the total hardness value of shale gas fracturing flowback fluid is unqualified, see image 3 , the processing method includes the following steps:

[0086] Step 201, after the gas-liquid separation of the initial shale gas fracturing flowback fluid 1 discharged from the wellhead during production of a shale gas well, use a floating pump impeller surface aerator (theoretical power efficiency is 2.6-2.8kgO 2 / kW·h) to blow air into it, so that the Fe in the initial shale gas fracturing flowback fluid 1 2+ Converted to Fe(OH) 3 , to obtain the oxidized shale gas fracturing flowback fluid 2.

[0087] Step 202, use the hydraulic fracturing analysis component of the HACH portable water quality analysis laboratory to detect the water quality of the oxidized shale gas fracturing flowback fluid 2, and mix it with the shale gas fracturing fluid of an oilfield service company W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com