Hoisting method for main engine equipment of vehicle passenger ferry

A technology of main engine equipment and hoisting method, which is applied in ship design, ship parts, ship construction, etc. It can solve the problems of tight order cycle requirements, high capital operation pressure, and early arrival time of the main engine, so as to achieve reliable fixing of the main engine and slow down The effect of pressure, precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

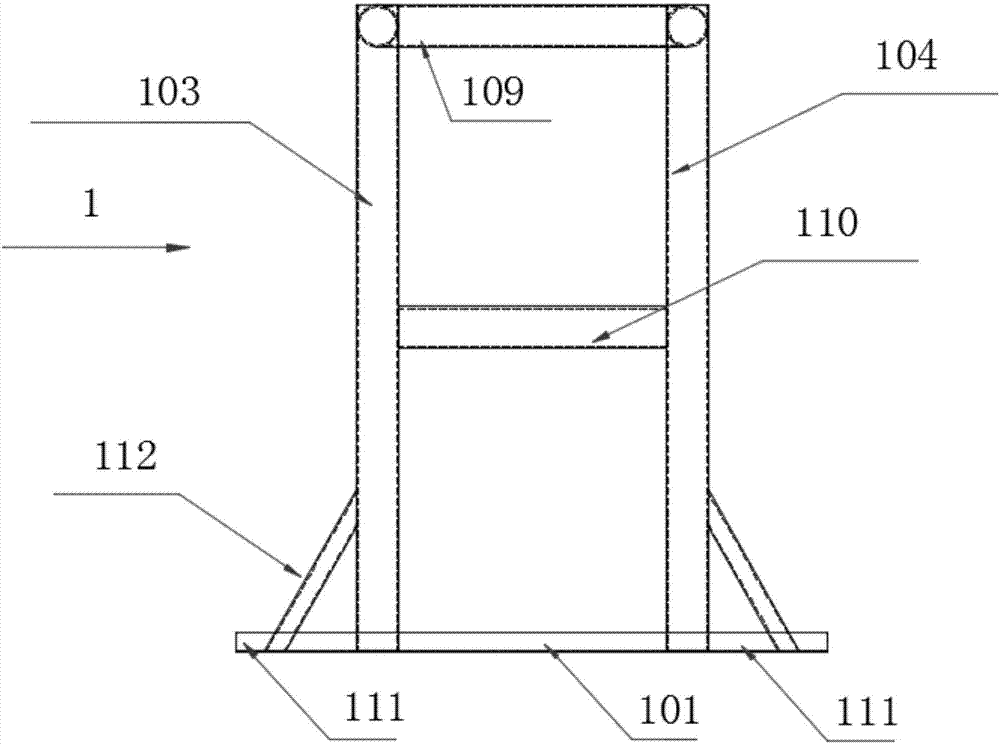

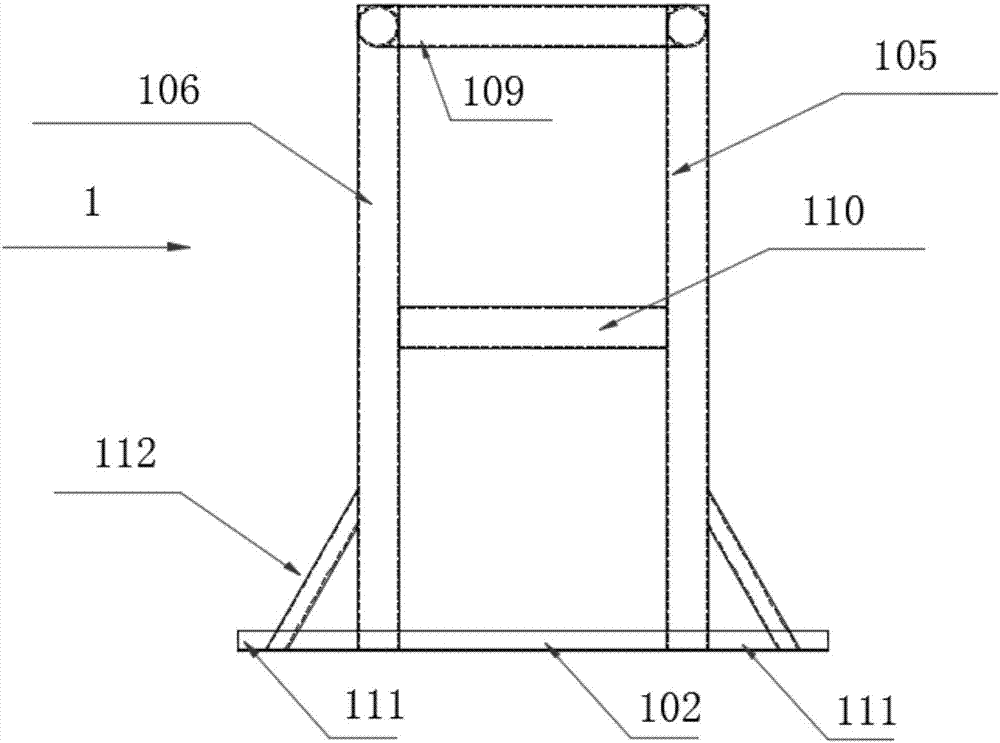

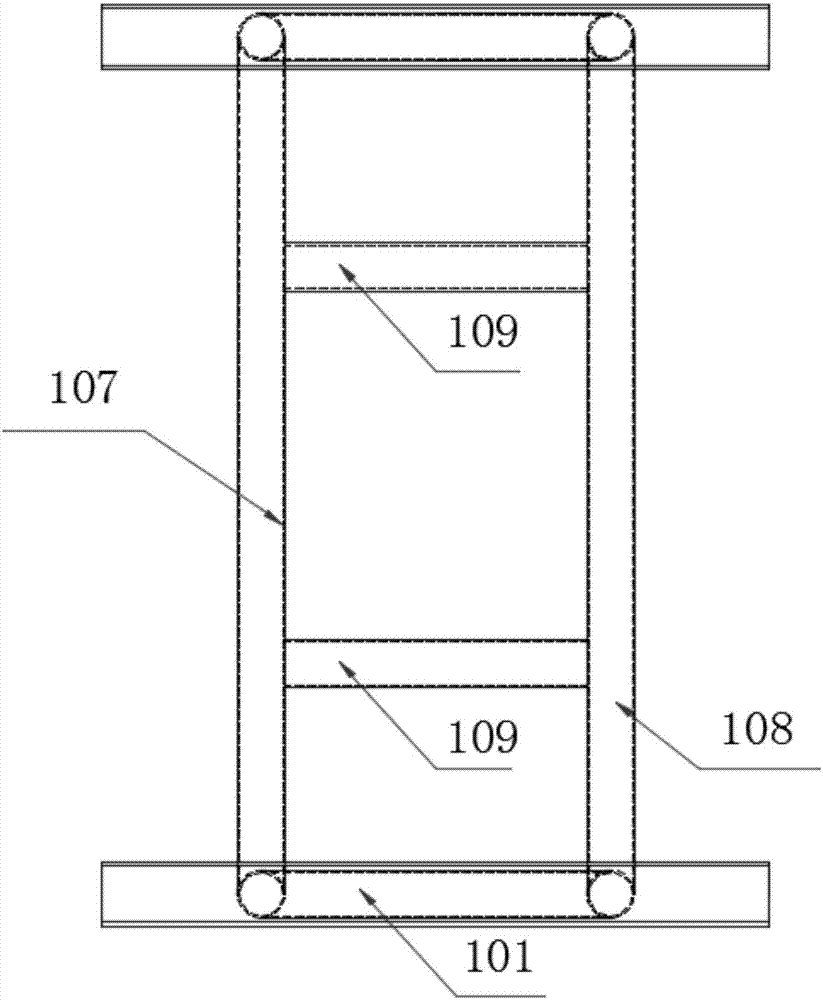

[0038] The traditional method of hoisting the main engine equipment of car-passenger ferries is difficult to operate because of the high hoisting height, and it is easy to cause damage to the main engine due to misoperation. The method for hoisting the main equipment of the car-passenger ferry of the present invention can be applied to the hoisting of the main equipment of small and medium-sized car-passenger ferries such as 50m, 60m, 74m, and 85m, and the weight of the main equipment is generally about 10 tons. The specific hoisting method includes the following steps:

[0039] Step 1, design the host hoisting mast tooling

[0040] like Figure 1-3 As shown, the portal frame tooling 1 adopted in the present invention includes a first horizontal base 101 and a second horizontal base 102 arranged front and back, and the two horizontal bases are preferably channel steel bases; the first horizontal base 101 is provided with The first vertical steel pipe 103, the second vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com