A Batch Forming Process for Building Elevation Concrete Blocks

A molding process and technology of concrete blocks, which are applied in the field of batch forming technology of building elevation concrete blocks, can solve the problems of easy breakage of elevation blocks and low yield of finished products, and achieve the effects of high symmetry, improved integrity, and reduced surface loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

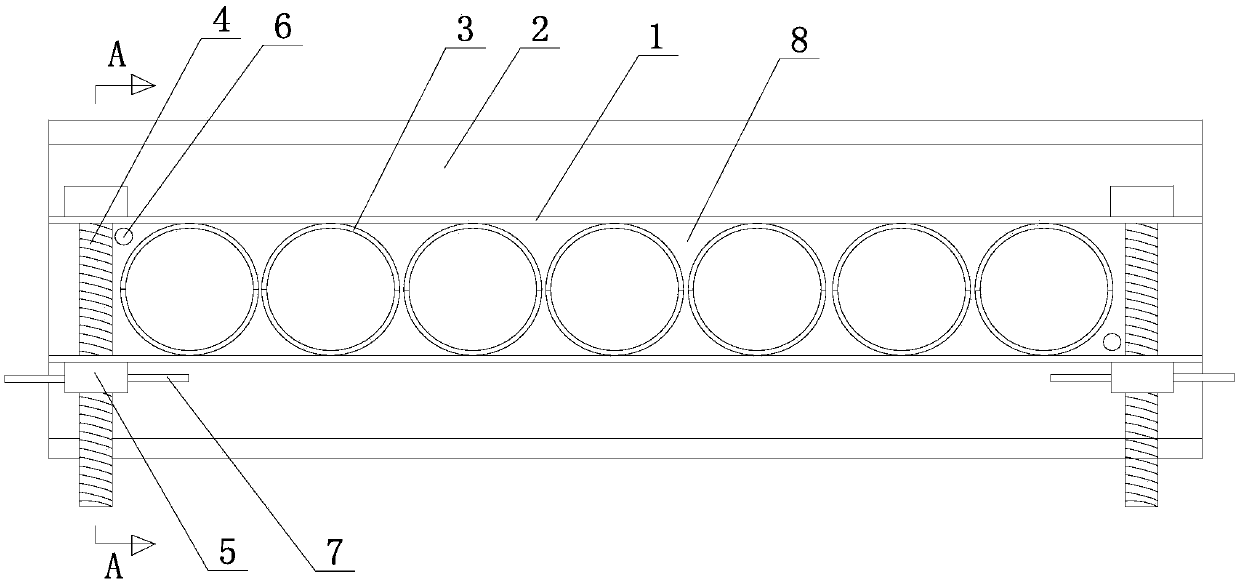

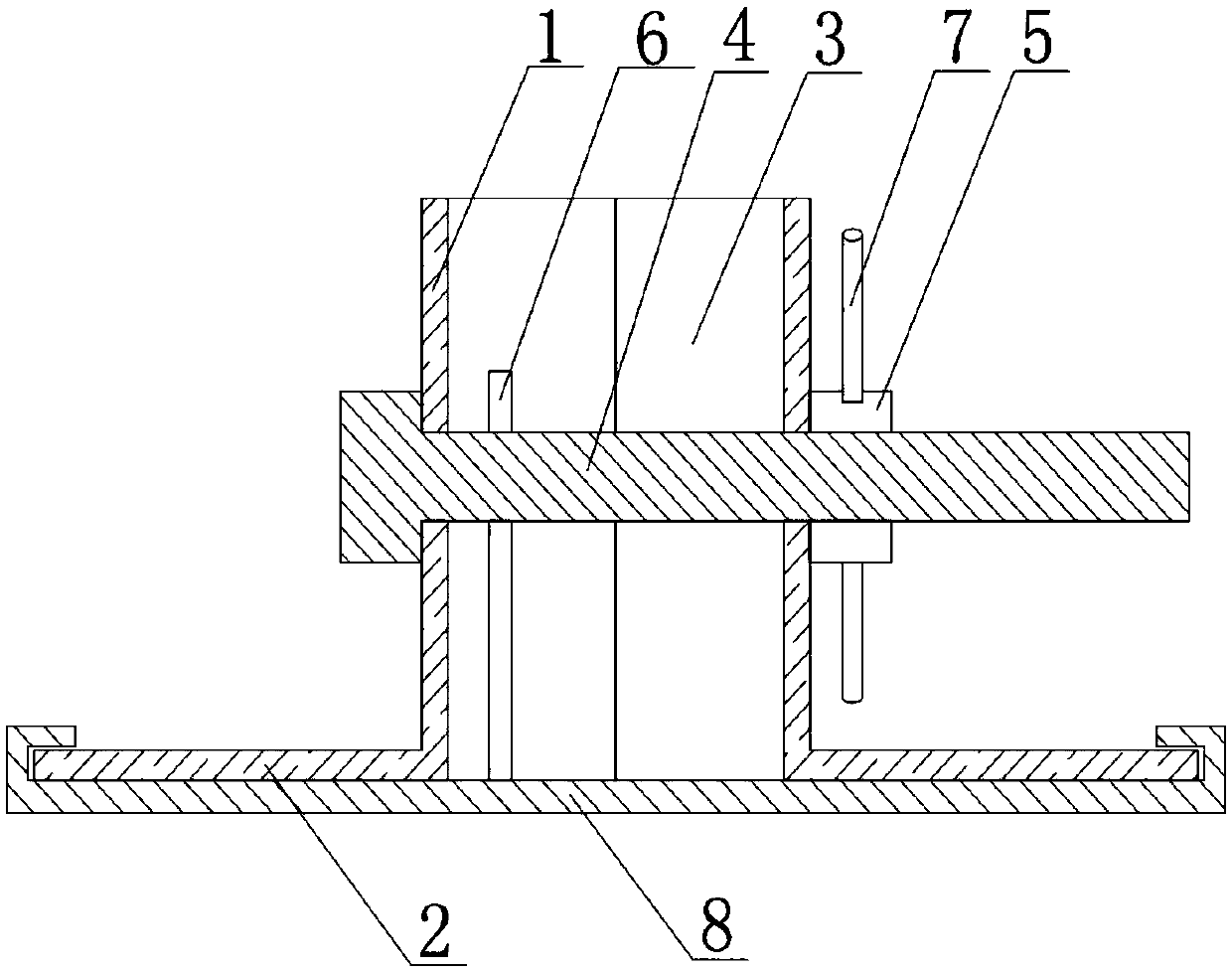

[0040] Such as Figures 1 to 2 As shown, a mold used in the batch molding process of building elevation concrete blocks in the present invention: it includes two splints 1 parallel to each other, and a plurality of semi-cylindrical ring plates 3 are arranged on the opposite side of the splints 1 , the ring plate 3 is paired between two splints 1 to form a cylindrical mold, and the bottom of each splint 1 is vertically provided with a plank 2 on the opposite side of the ring plate 3, and the two splints 1 pass at least two sets of paired bolts 4 is connected with the nut 5. The splint 1 and plank 2 in this embodiment are made of triangular steel, and the vertical uniformity of the height of the triangular steel can be used to realize the verticality of the plank and the splint, and the steel pipe is used as the ring plate 3 after half-sectioning. The ring plate is welded on the triangular steel, and a movable base 8 located under the plank 2 is also included. The movable base 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com