Indium-based two-component or three-component nanocatalyst as well as preparation and application thereof

A nano-catalyst and indium-based bicomponent technology, applied in the field of nano-materials, can solve the problems of difficult removal and cleaning of protective agents, influence on electrocatalytic performance, and environmental pollution by organic solvents, and achieve low production costs, mild conditions, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

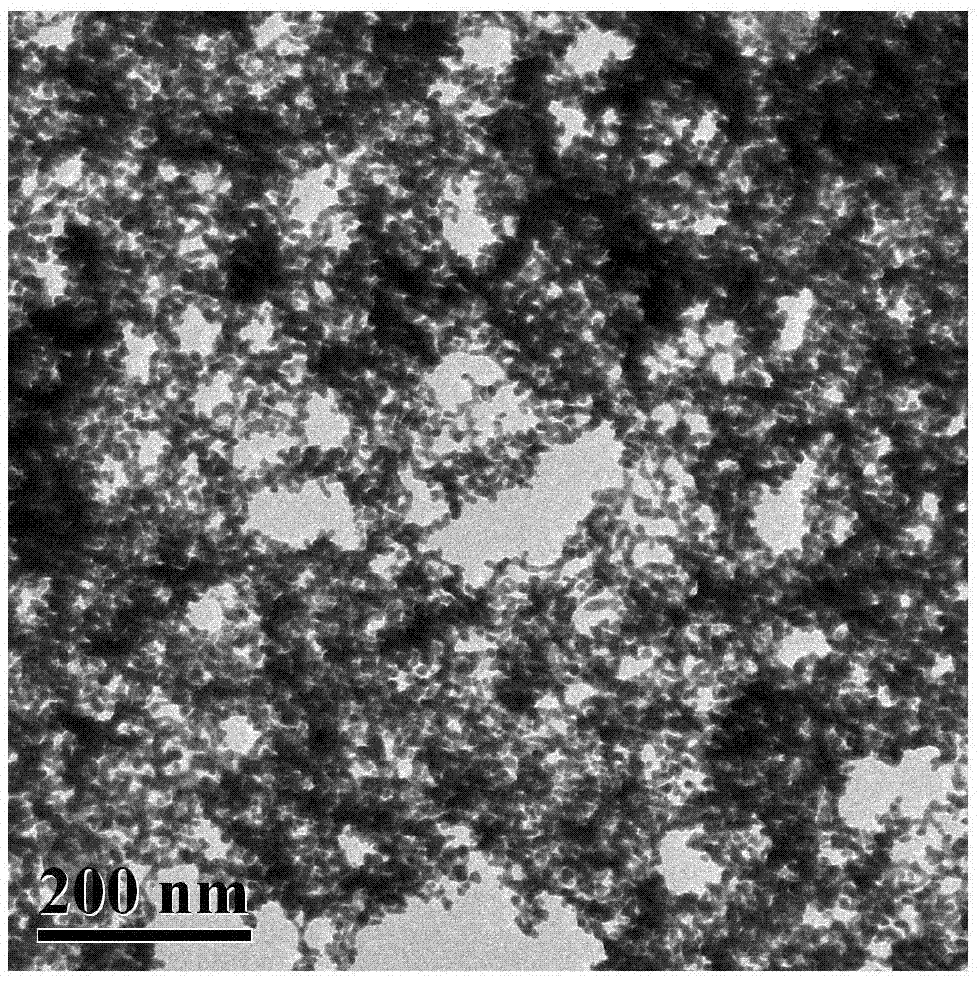

[0036] Example 1 In 2 Au nanocatalyst

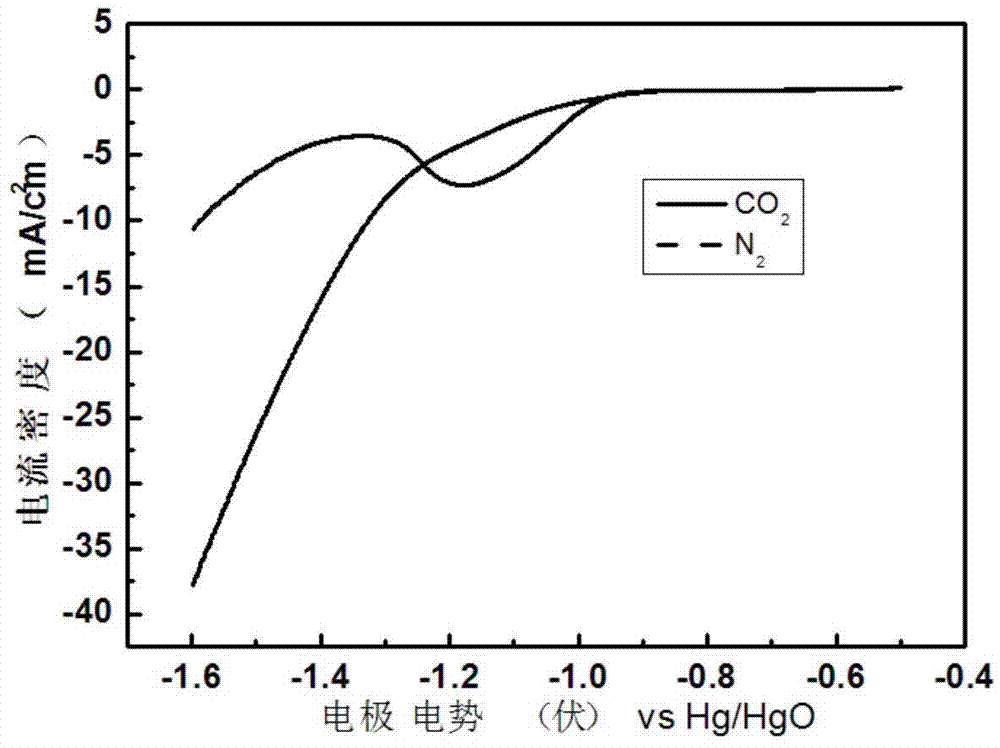

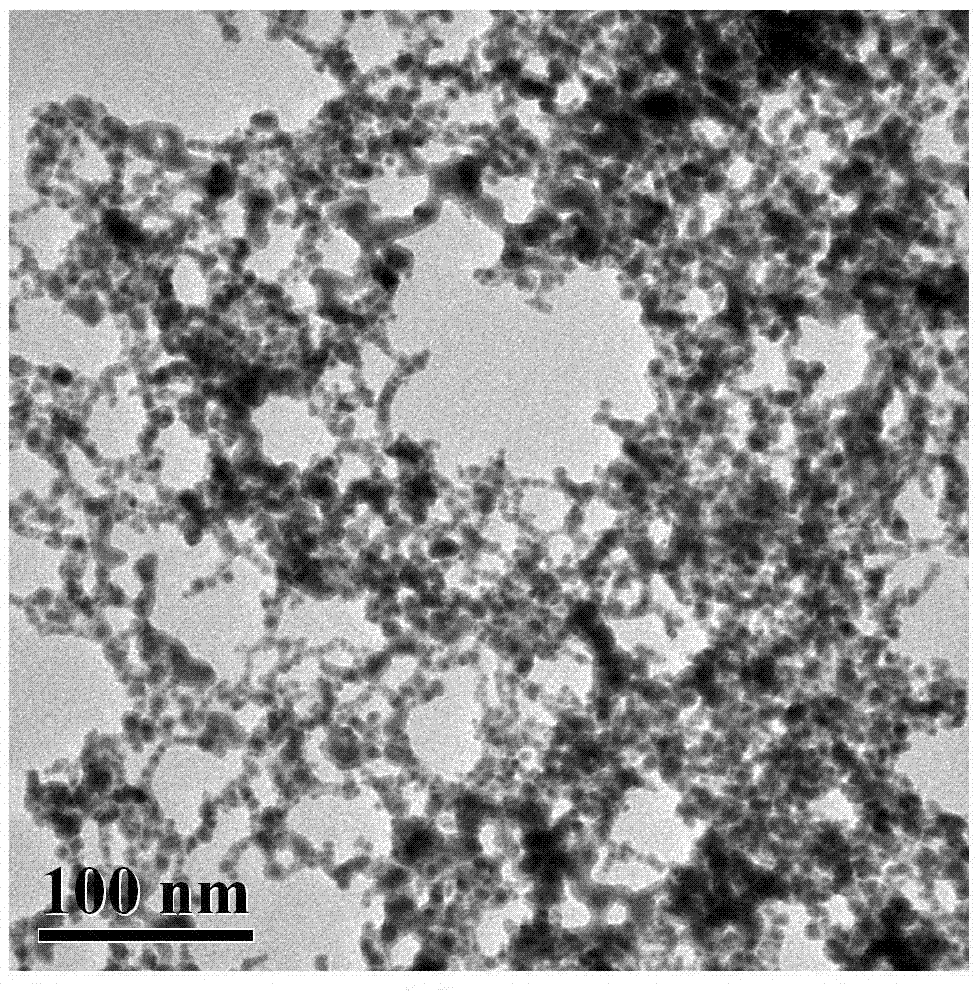

[0037] Pipette 16.7 mL of InCl 3 aqueous solution (20mM) and 8.33mL of AuCl 3 After the aqueous solution (20mM) was stirred and mixed uniformly in a 250mL flask, N was passed into the mixed solution. 2 , the nitrogen flow rate was 50 ml / min, and after 10 min, 25 mL of sodium borohydride aqueous solution (50 mM) was added to the above system. The reaction was stopped after 20 minutes of reaction. The reacted mixture was transferred to a centrifuge test tube, centrifuged to obtain a solid product, washed with water and ethanol several times respectively, and dried in a vacuum oven at 60°C for 10 hours to obtain In 2 Au nanorod catalysts. figure 1 For the prepared In 2 Transmission electron microscopy (TEM) of the Au catalyst. The obtained catalyst was subjected to CO 2 The activity evaluation of the electrochemical catalytic reduction reaction, the specific steps are as follows: the obtained In2 The Au catalyst is ultrasonically di...

Embodiment 2

[0038] Example 2 In 6 Au nanocatalyst

[0039] The difference between this embodiment and Embodiment 1 is that the ratio of In and Au in this embodiment is 6:1. The In 6 Au catalyst for CO 2 The electrochemical reduction reaction is catalytically active.

Embodiment 3

[0040] Example 3 In 9 Au nanocatalyst

[0041] The difference between this embodiment and Embodiment 1 is that the ratio of In and Au in this embodiment is 9:1. The In 9 Au catalyst for CO 2 The electrochemical reduction reaction is catalytically active.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com