Long-distance injection pipe down pipe device

A grouting pipe, long-distance technology, used in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem of large positioning error of grouting pipe, damaged grouting pipe structure, and work efficiency Influence and other issues, to achieve the effect of flexible production and use, improved quality and efficiency, and strong output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

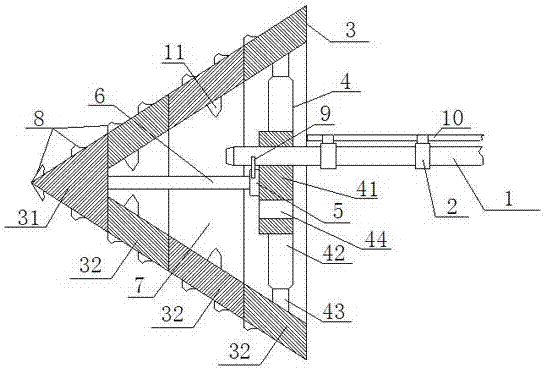

[0013] like figure 1 The long-distance grouting pipe lowering equipment includes a high-pressure driving water pipe 1, a tapered plug, and a connecting buckle 2. The tapered plug includes a breaking head 3, a bearing frame 4, a hydraulic motor 5 and a transmission shaft 6, The barrier head 3 is a hollow cone structure, the barrier breaking head 3 is provided with a bearing cavity 7, the bearing cavity 7 is coaxially distributed with the barrier breaking head 3, and at least two cutting edges 8 are evenly distributed on the outer surface of the barrier breaking head 3, and each cutting edge 8 are distributed in a spiral shape around the axis of the barrier-breaking head 3. The transmission shaft 6, the carrier frame 4 and the hydraulic motor 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com