E0-level melamine modified urea formaldehyde resin adhesive

A technology of urea-formaldehyde resin glue and melamine, which is used in aldehyde/ketone condensation polymer adhesives, adhesives, adhesive additives, etc., can solve the problems of unachievable sheet bonding performance, low formaldehyde emission, and long product production cycle. , to achieve the effect of improving utilization rate and production efficiency, reducing free formaldehyde, and good pre-pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

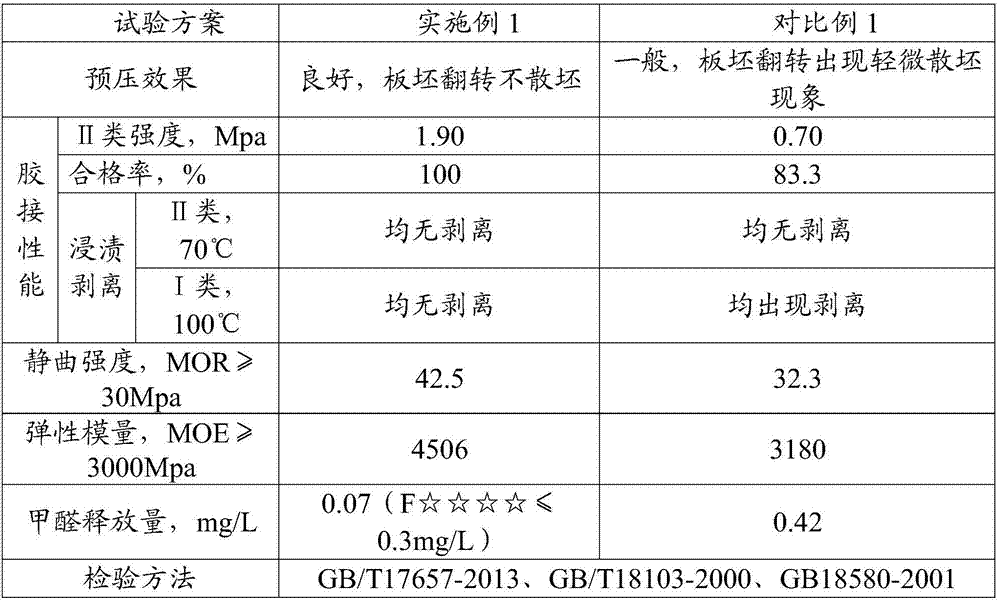

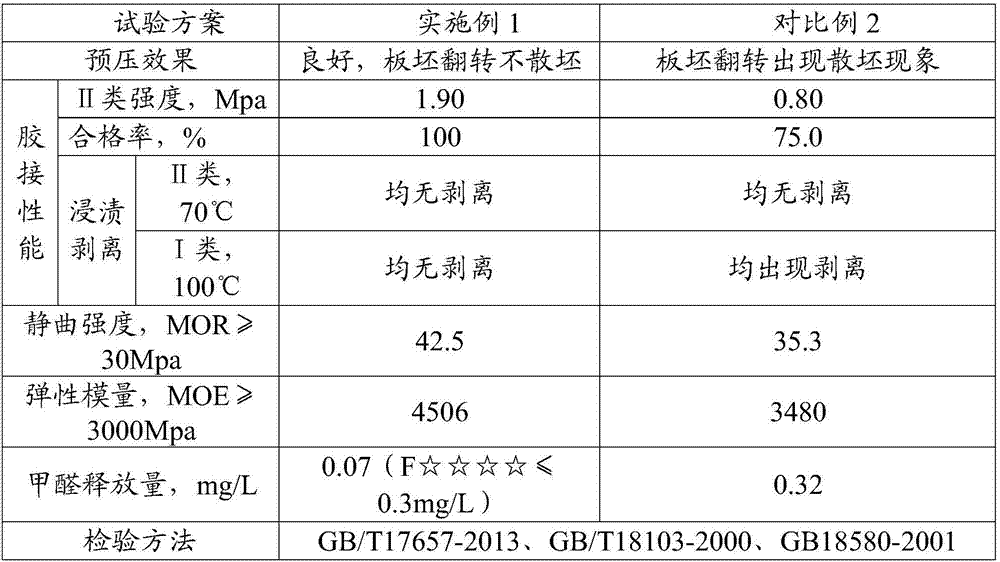

Examples

Embodiment 1

[0032] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0033] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0034](2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0035] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0036] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, c...

Embodiment 2

[0044] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0045] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0046] (2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0047] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0048] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, ...

Embodiment 3

[0056] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0057] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0058] (2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0059] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0060] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com