Motor brush frame and motor using same

A brush box and connecting frame technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of vibration and noise of brush frame motors, and achieve the effect of reducing vibration and generated noise, reducing noise, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

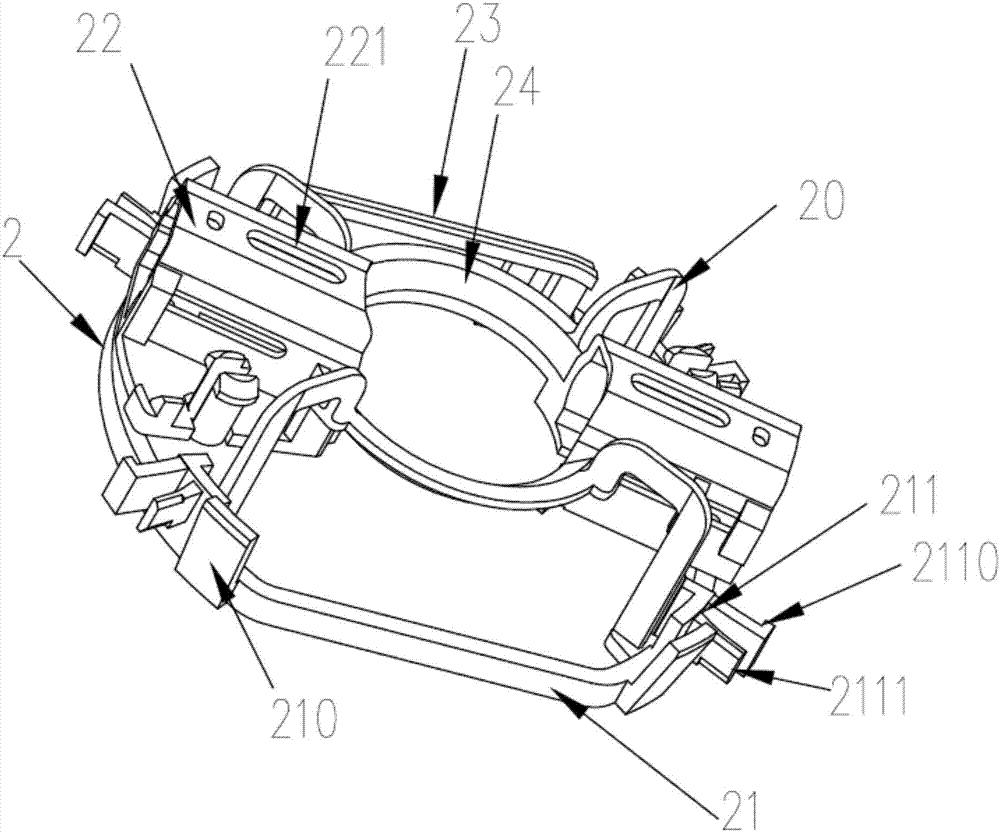

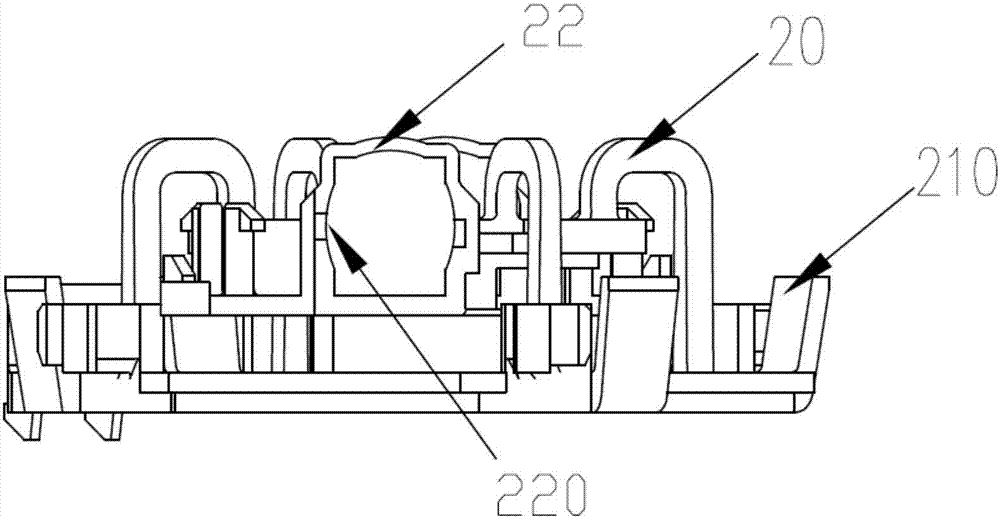

[0027] like Figure 2-5 As shown, the present invention provides a motor brush holder 2, including: a bracket 21 and a brush box 22 arranged on the bracket 21, the bracket 21 is a closed ring structure, which supports other components, and can be circular or square , polygon, etc., the present embodiment is elliptical; several thin-walled elastic connectors 20 are extended on the bracket 21, and the shape of the connectors can be set to an inverted "J" shape, "U" shape, or "L" shape One of them, in this embodiment, the shape of the connecting frame 20 is set to an inverted "J" shape, and the lower end of the connecting frame is symmetrically distributed on the bracket 21, that is, the head of the "J" shape is inverted on the bracket 21, and "J" The bent portion of the "-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com