P-type perc bifacial solar cell, component, system and preparation method thereof

A solar cell and double-sided technology, applied in the field of solar cells, can solve the problems of complex N-type double-sided cell technology and high price of N-type silicon wafers, and achieve the effects of improving photoelectric conversion efficiency, high photoelectric conversion efficiency, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

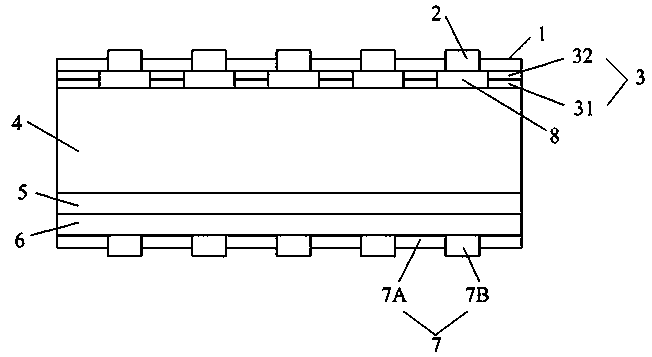

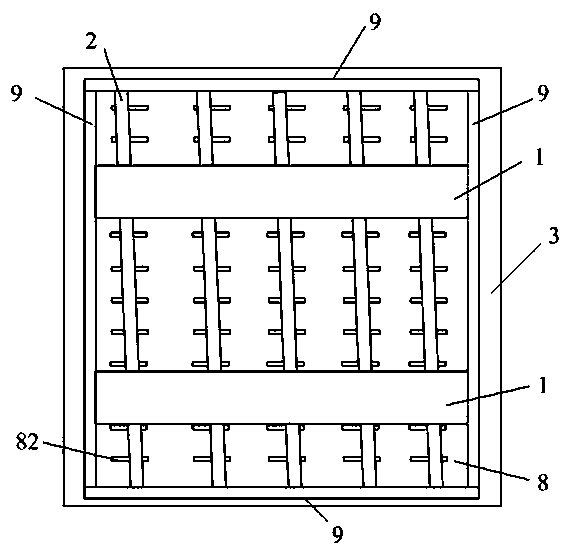

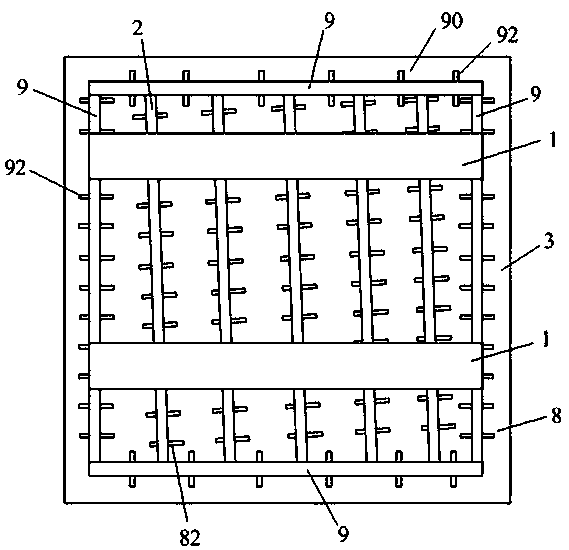

[0070] Further, the laser slotting unit set in the horizontal direction is taken as an example below, combined with Figure 4 , 5 To further illustrate the present invention, Figure 4 , 5 The dotted line box shown is the first laser grooving unit 81 , and each group of first laser grooving units 81 includes one or more first laser grooving bodies 82 . The first laser groove unit 81 has multiple implementations, including:

[0071] (1) Each group of first laser grooving units 81 includes a first laser grooving body 82. At this time, the first laser grooving units 81 are continuous linear grooving areas, specifically as Figure 5 shown.

[0072] (2) Each group of first laser grooving units 81 includes a plurality of first laser grooving bodies 82. At this time, the first laser grooving units 81 are line-segment non-continuous linear grooving areas, specifically as Figure 4 shown. The plurality of first laser grooved bodies 82 may be two, three, four or more, but not limi...

Embodiment 1

[0117] (1) Form a suede surface on the front and back of the silicon wafer, and the silicon wafer is P-type silicon;

[0118] (2) Diffusion of the silicon wafer to form an N-type emitter;

[0119] (3) Remove the front phosphosilicate glass and surrounding PN junctions formed during the diffusion process;

[0120] (4) Deposit aluminum oxide film on the back of the silicon wafer;

[0121] (5) Deposit a silicon nitride film on the back of the silicon wafer;

[0122] (6) Deposit a silicon nitride film on the front side of the silicon wafer;

[0123] (7) Laser grooving the back of the silicon wafer to form a first laser grooving area, the first laser grooving area includes multiple groups of first laser grooving units, each group of first laser grooving units includes one or more A first laser grooved body, the length of the first laser grooved body is 1000 microns, and the width is 40 microns;

[0124] (8) printing a back silver busbar electrode on the back of the silicon wafe...

Embodiment 2

[0131] (1) Form a suede surface on the front and back of the silicon wafer, and the silicon wafer is P-type silicon;

[0132] (2) Diffusion of the silicon wafer to form an N-type emitter;

[0133] (3) Remove the front phosphosilicate glass and surrounding PN junctions formed by the diffusion process, and polish the back of the silicon wafer;

[0134] (4) Deposit aluminum oxide film on the back of the silicon wafer;

[0135] (5) Deposit a silicon nitride film on the back of the silicon wafer;

[0136] (6) Deposit a silicon nitride film on the front side of the silicon wafer;

[0137] (7) Laser groove the back of the silicon wafer to form a first laser grooved area and a second laser grooved area. The first laser grooved area includes multiple groups of first laser grooved units, and each group of first laser grooved The groove unit includes one or more first laser grooved bodies, the length of the first laser grooved body is 500 microns, and the width is 50 microns;

[0138...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com