Developing device and developing processing method

A development device and processing method technology, which is applied in the field of photoresist development, can solve problems such as low product yield and TFT pattern size differences, and achieve the effects of improving product yield, reducing size differences, and flexible development processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

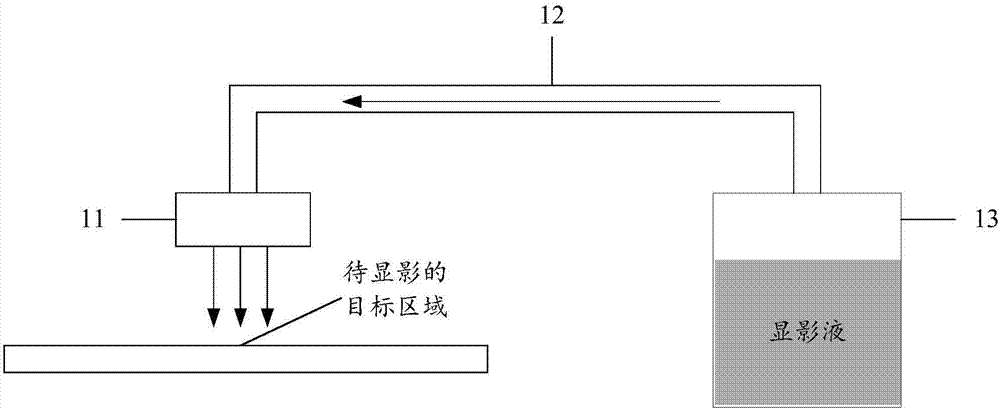

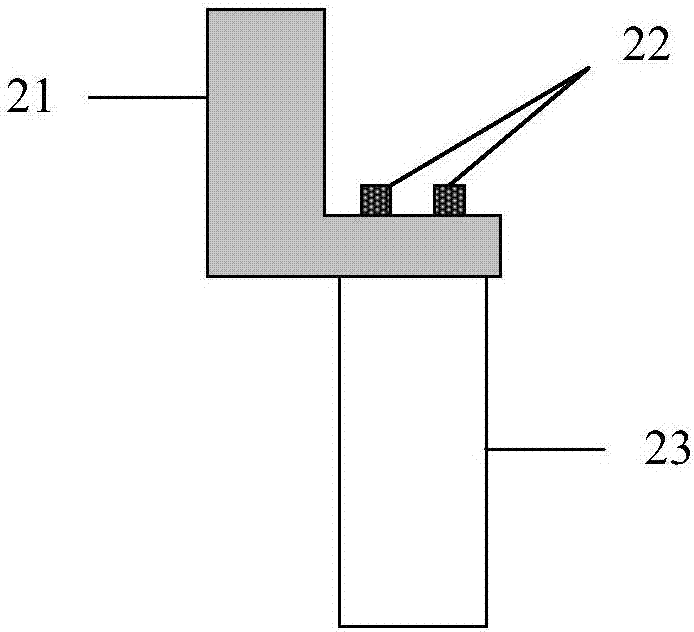

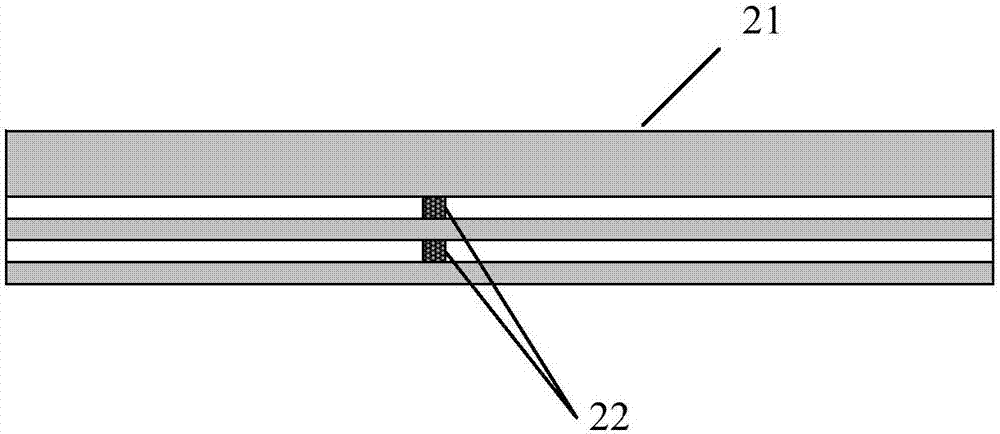

[0059] figure 1 It is a schematic structural diagram of a developing device provided in an embodiment of the present application, and the developing device can be used for developing a glass substrate to be developed. The developing device is as follows.

[0060] The developing device provided in the embodiment of the present application includes a developing nozzle 11, a connecting pipeline 12 and a developing box 13, wherein:

[0061] The developing box 13 is used to contain developing solution;

[0062] The connecting pipeline 12 is used to communicate with the developing nozzle 11 and the developing tank 13, and deliver the developing solution to the developing nozzle 11;

[0063] The developing nozzle 11 is used to spray the developing solution to the target area to be developed, and the position of the developing nozzle 11 is adjustable.

[0064] Such as figure 1 As shown, the developing tank 13 can be filled with developer for developing treatment, one end of the co...

Embodiment 2

[0103] Figure 5 It is a schematic flow chart of a developing processing method provided in the embodiment of the present application, and the developing processing method can be implemented by the developing device described in the above-mentioned embodiment 1. The method is described below.

[0104] In the embodiment of the present application, the glass substrate covered with photoresist is developed again (or multiple times) to realize the compensation of the size of the obtained TFT pattern as an example for illustration.

[0105] Step 501: Determine the target area to be developed.

[0106] In step 501 , before the photoresist on the glass substrate needs to be developed again, the target area to be developed that needs to be developed again can be determined. In the embodiment of the present application, the target area to be developed may be an area where the size of the TFT pattern on the glass substrate does not meet the standard.

[0107] In the embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com