Circular grating installation error calibration and correction method based on single reading head

An installation error and error correction technology, which is applied in the field of calibration and correction of circular grating installation errors based on a single reading head, can solve problems such as low cost, and achieve the effect of reducing high difficulty requirements and improving error correction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

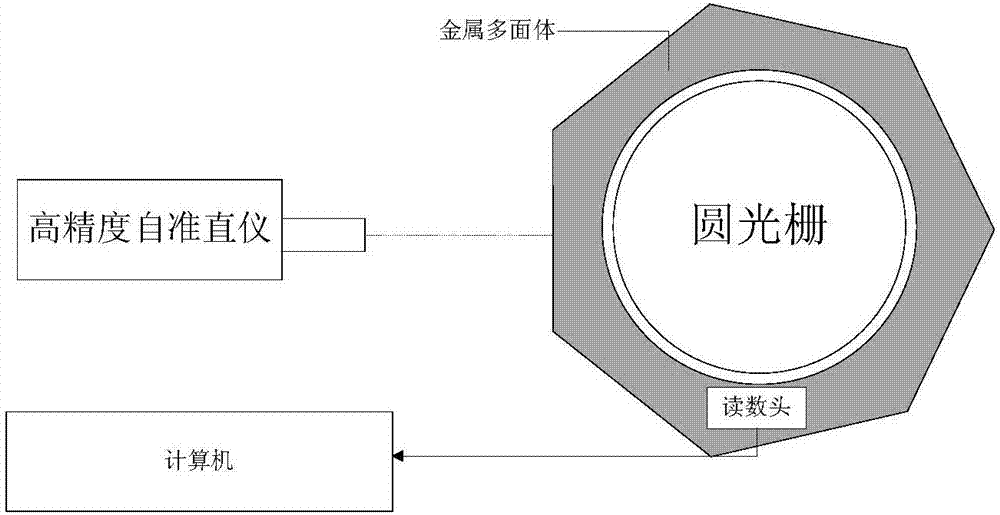

[0025] combine figure 1 with 2 Illustrate the embodiment of the present invention, the hardware is made of dial indicator, 24 metal polyhedrons and high-precision autocollimator (accuracy 1 "), computer. On the software, the acquisition software, calibration software and data correction processing software run on the computer Composition. The specific implementation method is as follows:

[0026] Step 1. During the installation of the circular grating by the installer, use a dial indicator to measure the eccentricity, radial runout and end runout of the circular grating; check whether the eccentricity, radial runout and end runout are within 10 μm, and if they are within 10 μm, proceed to step 2 Install the metal polyhedron; if it is not within 10 μm, adjust the circular grating until the eccentricity, radial jump and end jump are within 10 μm;

[0027] Step 2. Use tooling to install the metal polyhedron on the rotating part to ensure that the metal polyhedron moves synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com