Garbage incinerator sludge direct mixing blending combustion method and system

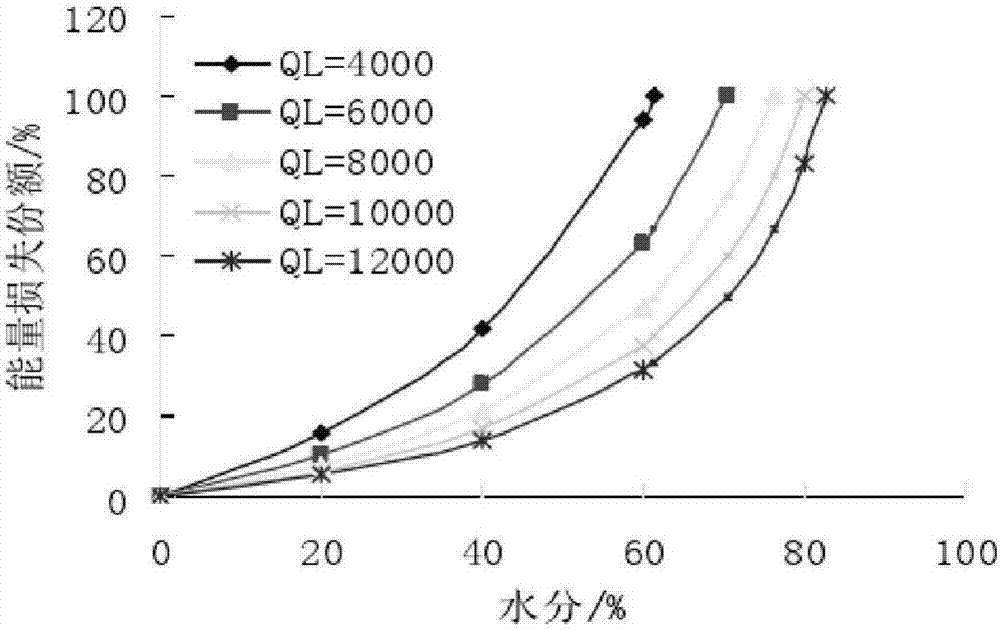

A waste incinerator and sludge technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of reduced power generation, lower calorific value, and inability to catch fire, etc., to achieve fast processing speed and improved ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

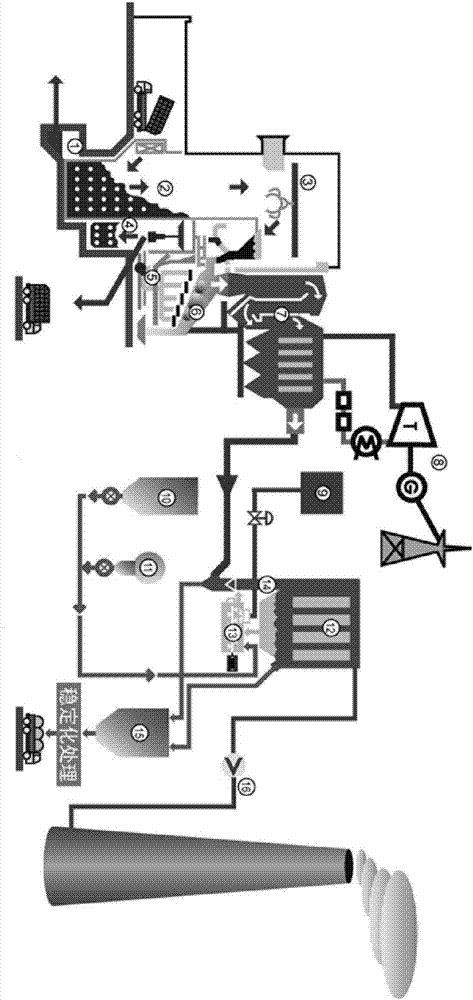

[0069] refer to figure 2 , figure 2 It shows the garbage sludge mixed incineration incineration system of the present invention, which includes: garbage sludge unloading unit, garbage temporary storage mixing and stirring unit, garbage transfer unit, garbage sludge incineration unit, thermal energy conversion unit, power generation unit, Flue gas treatment unit. The collected domestic garbage and sludge are dumped by the garbage (sludge) transport vehicle into the garbage temporary storage mixing unit through the unloading platform. After a certain period of fermentation and dehydration in the temporary storage mixing unit, and fully stirred and mixed evenly, it enters the garbage sludge and mixes it into the furnace transfer unit. The garbage transfer unit is located above the garbage temporary storage mixing unit and the garbage incineration unit. Transfer from the garbage temporary storage mixing unit to the garbage incineration unit. The waste incineration unit is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com