Main pump shaft seal injection water system of nuclear power plant

A technology for water injection and nuclear power plant, applied in the field of nuclear power, can solve the problems of unable to establish natural circulation, unable to realize exhaust gas, affecting the normal operation of shaft seal injection water system, etc., to optimize system structure and control, ensure safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

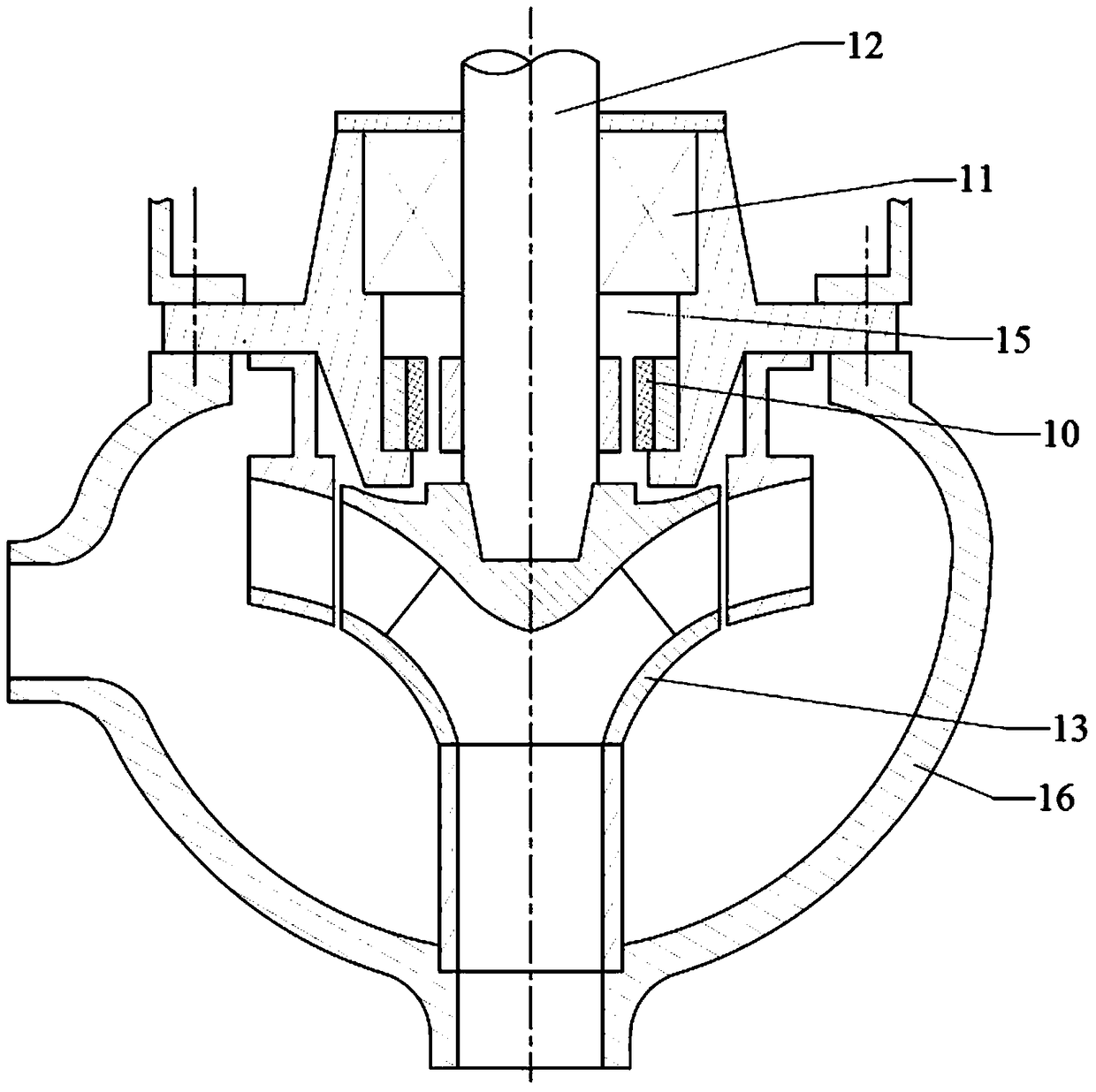

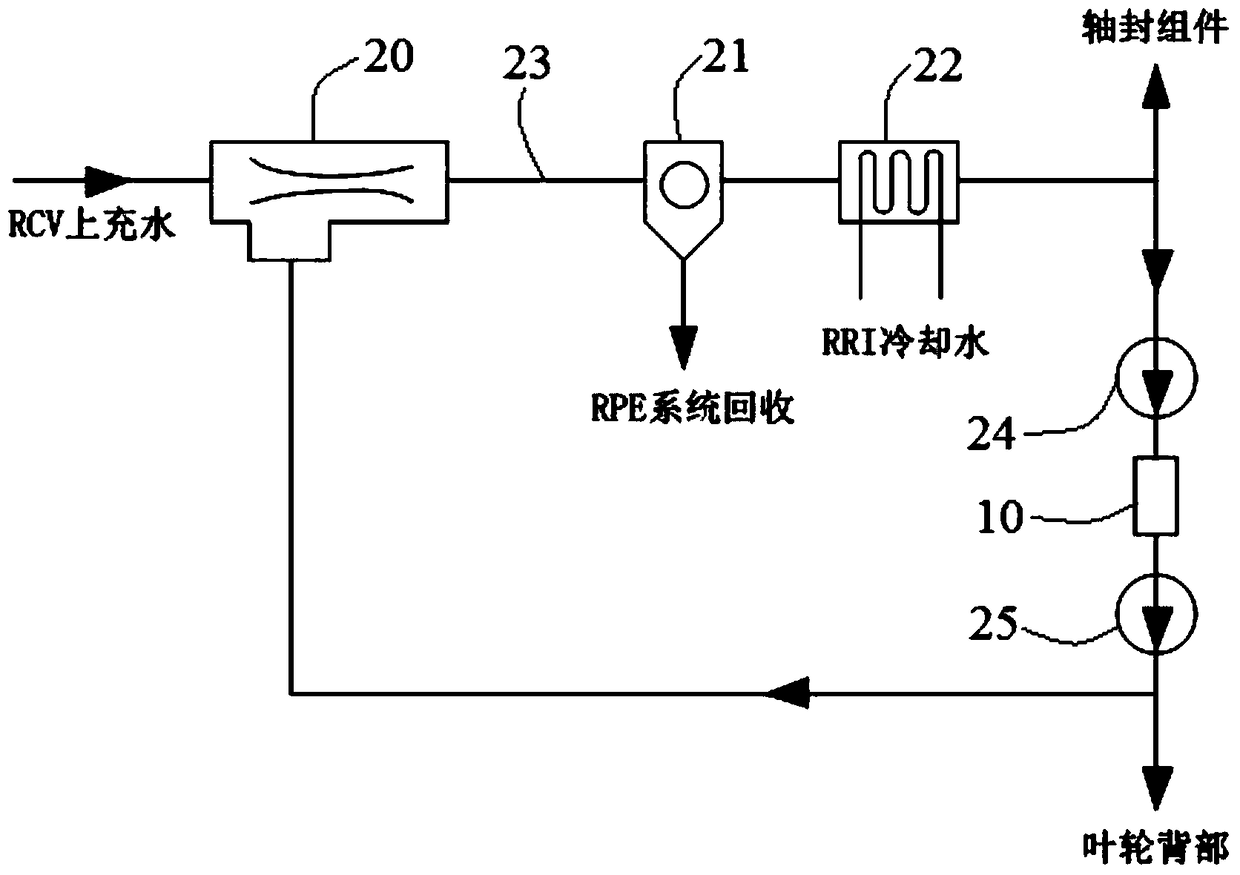

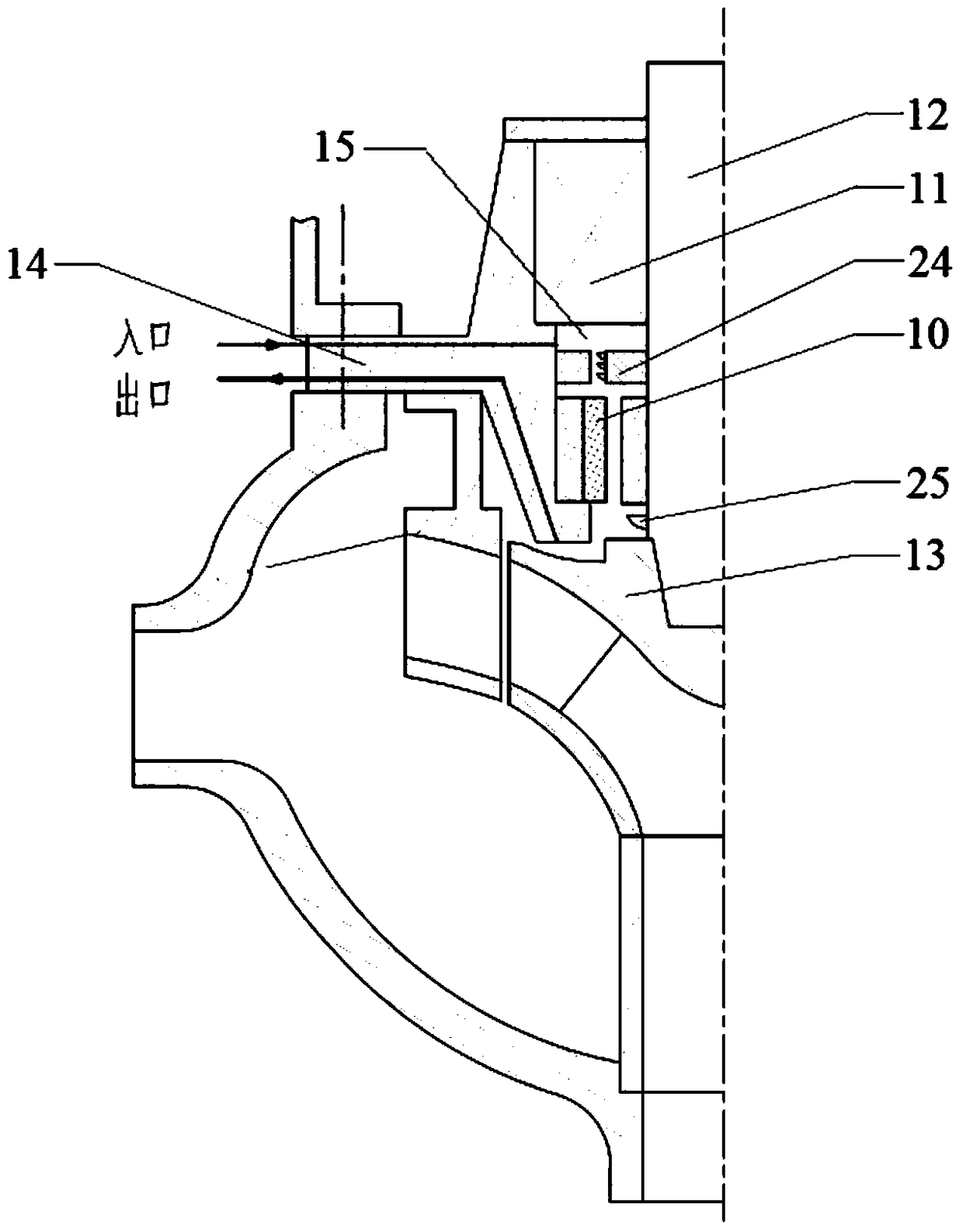

[0030] see Image 6 with Figure 7 , the nuclear power plant main pump shaft seal water injection system of the present invention includes a jet pump 50, a high-pressure cooler 51, a hydrocyclone 52, a plurality of valves, connecting pipes and a pressure sensor 54 arranged outside the main pump, and a water injection system arranged inside the main pump. The auxiliary pump 55 and the internal flow passage of the main pump are connected through the shaft seal water injection hole and the high-temperature water drainage hole on the main flange 14a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com