A horizontal enthalpy increasing compressor

A compressor and horizontal technology, applied in the field of horizontal enthalpy increasing compressors, can solve the problems of high height and large volume, and achieve the effects of reducing costs, miniaturizing the structure, and facilitating processing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

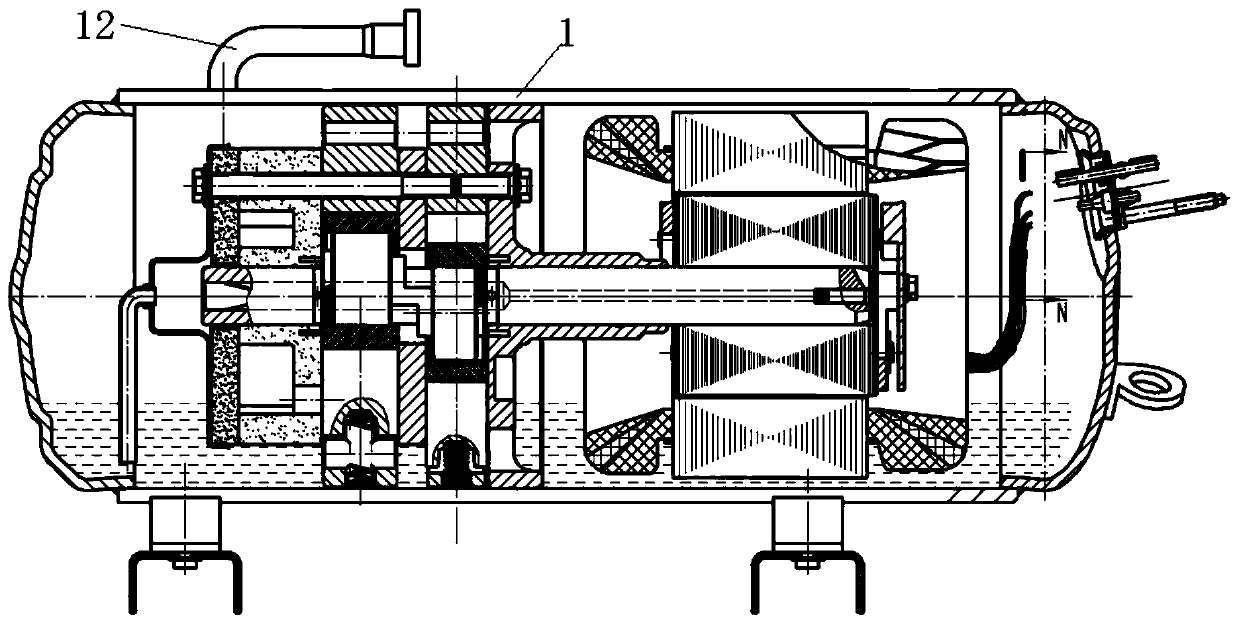

[0030] like Figure 3-6 As shown, the present invention provides a horizontal enthalpy increasing compressor, which includes a casing 1 and an upper flange 2 arranged in the casing 1 along the axial direction of the casing 1, an upper cylinder 3, and a partition 4. Lower cylinder 5, lower flange 6 and lower cover plate 7, (such as Figure 4 As shown, the upper flange 2, the upper cylinder 3, the separator 4, the lower cylinder 5, the lower flange 6 and the lower cover plate 7 are arranged in sequence along the axial direction, that is, they are arranged in sequence from right to left in the figure) The flange 6 has a medium-pressure chamber 8 communicating with the air inlet of the lower cylinder 5, and also includes an enthalpy-increasing air supply pipe 9, and the enthalpy-increasing air supply pipe 9 passes through the lower cover plate 7 from the outside of the compressor It penetrates into the interior of the compressor (medium-pressure chamber 8), and is used to repleni...

Embodiment 2

[0038] like Figure 4, as shown in 7-8, this embodiment is a further improvement made on the basis of embodiment 1, preferably, it also includes an exhaust pipe 12, and the exhaust pipe 12 passes from the outside of the compressor through the The lower cover plate 7 penetrates into the compressor and is used for exhausting the compressor. By penetrating the exhaust pipe from the outside of the compressor into the interior of the compressor through the lower cover plate, it is used to exhaust the compressor. In terms of exhausting to the outside of the compressor, the exhaust pipe is effectively arranged on the lower cover plate on the lateral side of the horizontal compressor, so that the horizontal compressor can be effectively reduced while protruding upwards. The height of the top of the compressor effectively reduces the volume of the compressor, making the structure more miniaturized, simple in structure, easy to produce in batches, and reduces the cost; the invention ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com