Magnetic levitation auxiliary supporting plunger pump

A support column and maglev technology, applied in the direction of pumps, multi-cylinder pumps, pump components, etc., to achieve the effects of improving force, reducing maximum contact stress, and reducing wear of sliding shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

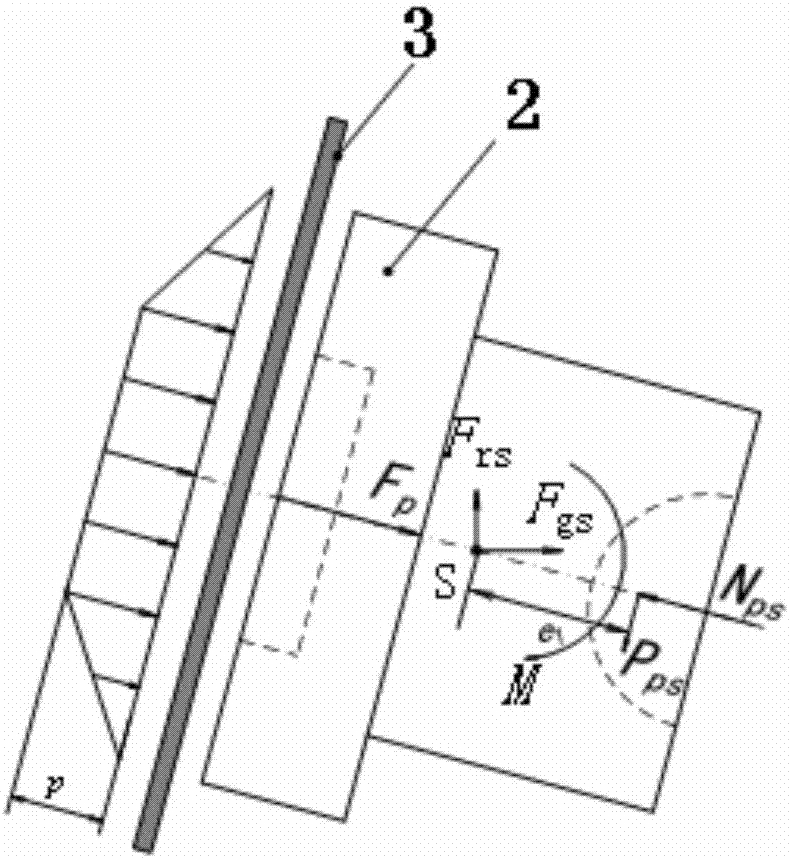

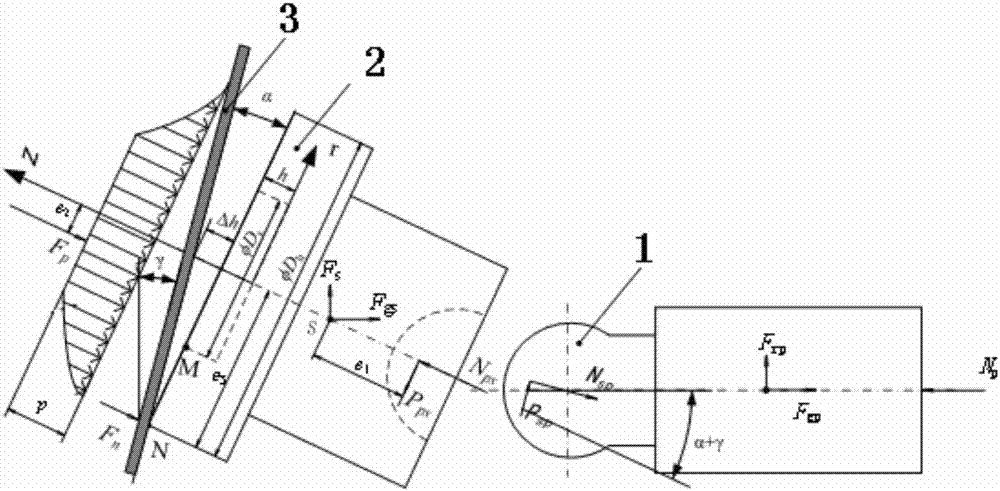

[0023] Such as Figure 3-Figure 6 As shown, the present invention includes a plunger 1, a sliding shoe 2 and a swash plate 3; the plunger 1 is connected to the sliding shoe 2 through a spherical hinge; the end of the sliding shoe 2 facing away from the spherical hinge is placed on the swash plate 3 in the sliding shoe slideway 31. The sliding shoe 2 and the swash plate 3 are respectively provided with magnetic fields with opposite polarities, and the resultant force of the repulsive force of the magnetic field on the sliding shoe 2 does not pass through the center of mass of the sliding shoe 2 . The repulsive force generated by the two magnetic fields acts on the center of mass of the sliding shoe 2 to balance the tilting moment of the contact force of the ball head of the plunger 1 on the center of mass of the sliding shoe 2, so that the thickness of the oil film bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com