Self-resetting wane type friction composite damper

A compound damping and variable friction technology, applied in the direction of protective buildings/shelters, building components, building types, etc., can solve problems such as the adverse effect of outer tube stiffness, achieve sufficient energy consumption, avoid friction, and reduce excessive speed. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

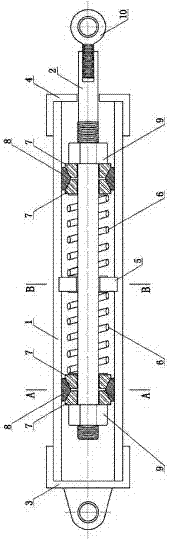

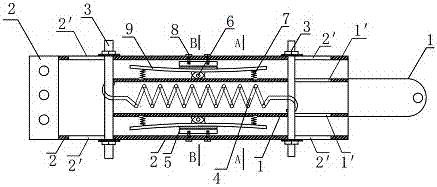

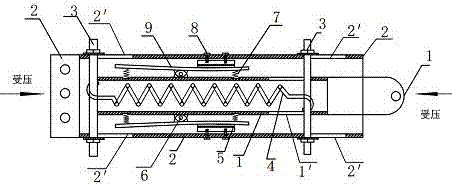

[0012] Such as figure 2 , Figure 6 As shown, the present invention is a self-resetting seesaw type variable friction compound damper. There is an inner tube 1, which is provided with a first bolt slot slideway 1´ that runs through the inner tube 1. The right end of the inner tube 1 has a Connecting key; On the outer tube 2, there are two second bolt slotted hole slideways 2´ that run through the outer tube 2, the length of the second bolt slotted hole slideway 2´ is equal to that of the first bolt slotted hole slideway 1´, and There are four threaded holes; there is a connection key at the left end of the outer tube 2; the sliding bolt assembly 3 is installed in the first bolt slotted hole slideway 1´ and the second bolt slotted hole slideway 2´ of the inner and outer tube; and the sliding bolt assembly 3 and the outer tube 2 are clearance fit; the elastic body 4 is placed in the inner tube 1, and the two ends of the elastic body 4 have hooks, which are respectively hung on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com