Concrete pouring method of concrete heat insulating curtain wall

A technology of concrete and thermal insulation curtain, which is applied in the direction of construction, building structure, and construction material processing, etc. It can solve the problems of thermal insulation board displacement, failure to meet design requirements, difficulties, etc., and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

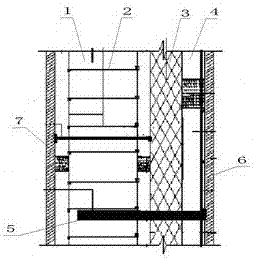

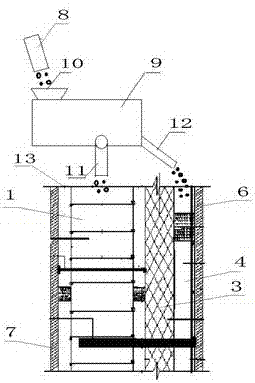

[0025] Referring to 2, in the figure, the concrete pouring method of the concrete thermal insulation curtain wall of the present invention comprises the following process steps:

[0026] (1) Concrete preparation:

[0027] According to the thickness of structural concrete and surface layer concrete, the aggregate particle size of concrete adopts segmental continuous grading; among them, stones with a particle size of 5-10mm account for 15-20% of the total amount of stones, and stones with a particle size of 10-30mm account for 80-85% of the total amount of stones, and the slump of the concrete mixture is 160-180mm;

[0028] (2) Concrete pouring:

[0029] The equipment used in the concrete pouring process is a concrete pump and a concrete separation device 9, wherein the concrete separation device 9 is located directly above the concrete pouring work surface 13, and the outlet of the concrete pump pipe 8 contained in the concrete pump is directly facing the concrete separation ...

Embodiment 2

[0036] Referring to 2, in the figure, the concrete pouring method of the concrete thermal insulation curtain wall of the present invention comprises the following process steps:

[0037] (1) Concrete preparation:

[0038] According to the thickness of structural concrete and surface layer concrete, the aggregate particle size of concrete adopts segmental continuous grading; among them, stones with a particle size of 5-10mm account for 15-20% of the total amount of stones, and stones with a particle size of 10-30mm account for 80-85% of the total amount of stones, and the slump of the concrete mixture is 160-180mm;

[0039] (2) Concrete pouring:

[0040] The equipment used in the concrete pouring process is a concrete pump and a concrete separation device 9, wherein the concrete separation device is located directly above the concrete pouring work surface, and the outlet of the concrete pump pipe contained in the concrete pump is directly opposite to the feed inlet of the conc...

Embodiment 3

[0048] Referring to 2, in the figure, the concrete pouring method of the concrete thermal insulation curtain wall of the present invention comprises the following process steps:

[0049] (1) Concrete preparation:

[0050] According to the thickness of structural concrete and surface layer concrete, the aggregate particle size of concrete adopts segmental continuous grading; among them, stones with a particle size of 5-10mm account for 15-20% of the total amount of stones, and stones with a particle size of 10-30mm account for 80-85% of the total amount of stones, and the slump of the concrete mixture is 160-180mm;

[0051] (2) Concrete pouring:

[0052] The equipment used in the concrete pouring process is a concrete pump and a concrete separation device 9, wherein the concrete separation device is located directly above the concrete pouring work surface, and the outlet of the concrete pump pipe contained in the concrete pump is directly opposite to the feed inlet of the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com