Frame system composed of hollow steel pipe concrete integral joints and construction method

A technology of concrete filled steel tubes and integral joints, which is applied in the direction of building structure and construction, can solve the problems of difficult joint connection, complicated joint connection between columns and beams, and easy to be damaged, so as to achieve convenient construction, shorten construction period, and avoid formwork. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

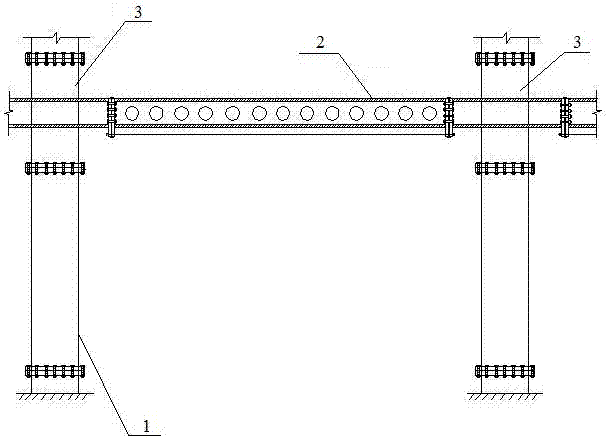

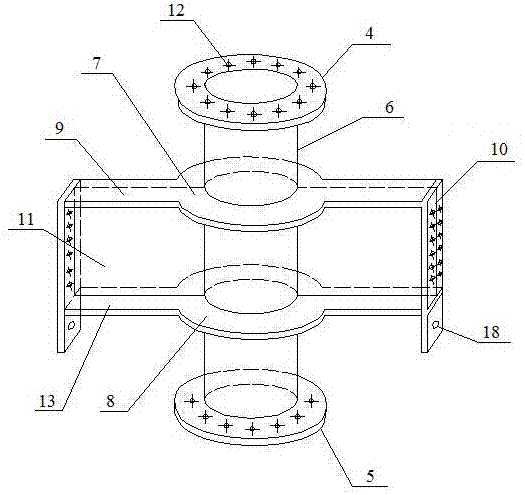

[0041] combine figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 12 , Figure 13 , Figure 14 As shown, the frame system composed of integral joints of hollow concrete-filled steel tubes is composed of composite columns 1 and composite beams 2 connected by joints 3, composite beams 2 are horizontally arranged between composite columns 1, and joints 3 are the overall outer shell filled with high-strength concrete The integral node of the outer jacket includes a node outer tube 6 with an upper connecting ring 4 and a lower connecting ring 5. Both the upper connecting ring 4 and the lower connecting ring 5 are provided with bolt holes 12, and the upper part of the node outer tube 6 has an upper reinforcement The ring plate 7 has a lower reinforcing ring plate 8 on the lower part, the upper reinforcing ring plate 7 extends horizontally outwards to form the upper flange 9 of the I-shaped end beam, and the lower reinforcin...

Embodiment 2

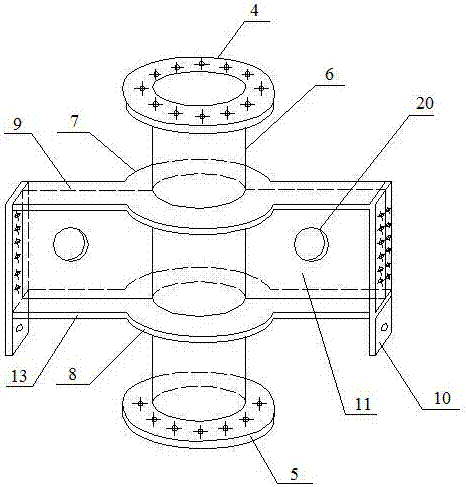

[0051] The frame system composed of hollow concrete-filled steel tube integral joints is composed of composite columns 1 and composite beams 2 connected by joints 3, the composite beams 2 are horizontally arranged between the composite columns 1, and the joints 3 are outer-coated integral joints filled with high-strength concrete 19 The integral node of the outer jacket includes a node outer tube 6 with an upper connecting ring 4 and a lower connecting ring 5, the upper connecting ring 4 and the lower connecting ring 5 are provided with bolt holes 12, and the upper part of the node outer tube 6 has an upper reinforcing ring plate 7. There is a lower reinforcing ring plate 8 in the lower part, and the upper reinforcing ring plate 7 extends horizontally outward to form the upper flange 9 of the I-shaped end beam whose inner cavity is connected. The lower flange 13 of the I-shaped end beam, the joint web 11 between the upper flange 9 and the lower flange 13 of the I-shaped end bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com