A method and system for improving the efficiency of pipe network leakage control

A technology for controlling efficiency and leakage, applied in pipeline systems, general water supply conservation, gas/liquid distribution and storage, etc., can solve problems such as lack of scientific basis, unsatisfactory leakage control effect, and low efficiency of water supply network leakage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

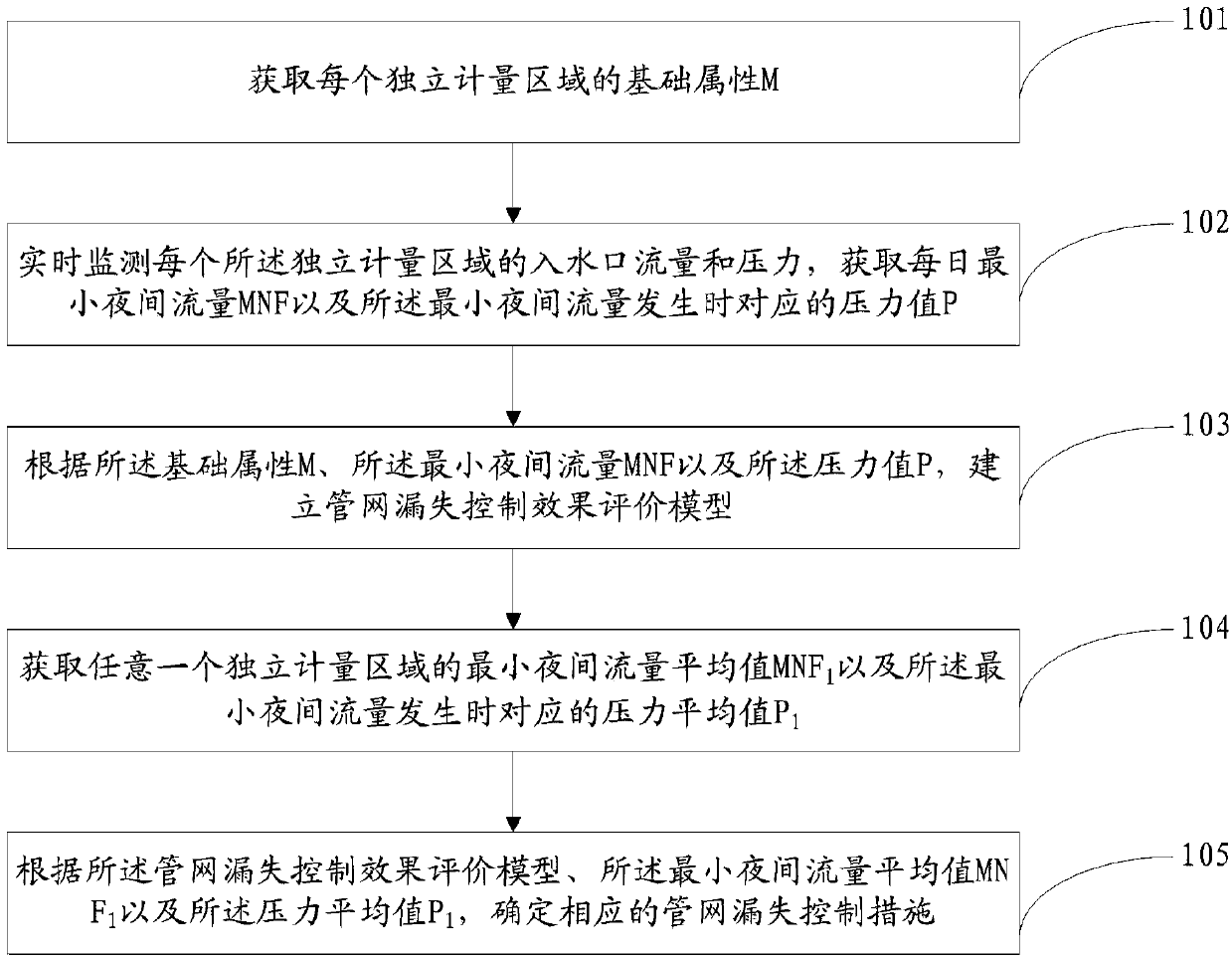

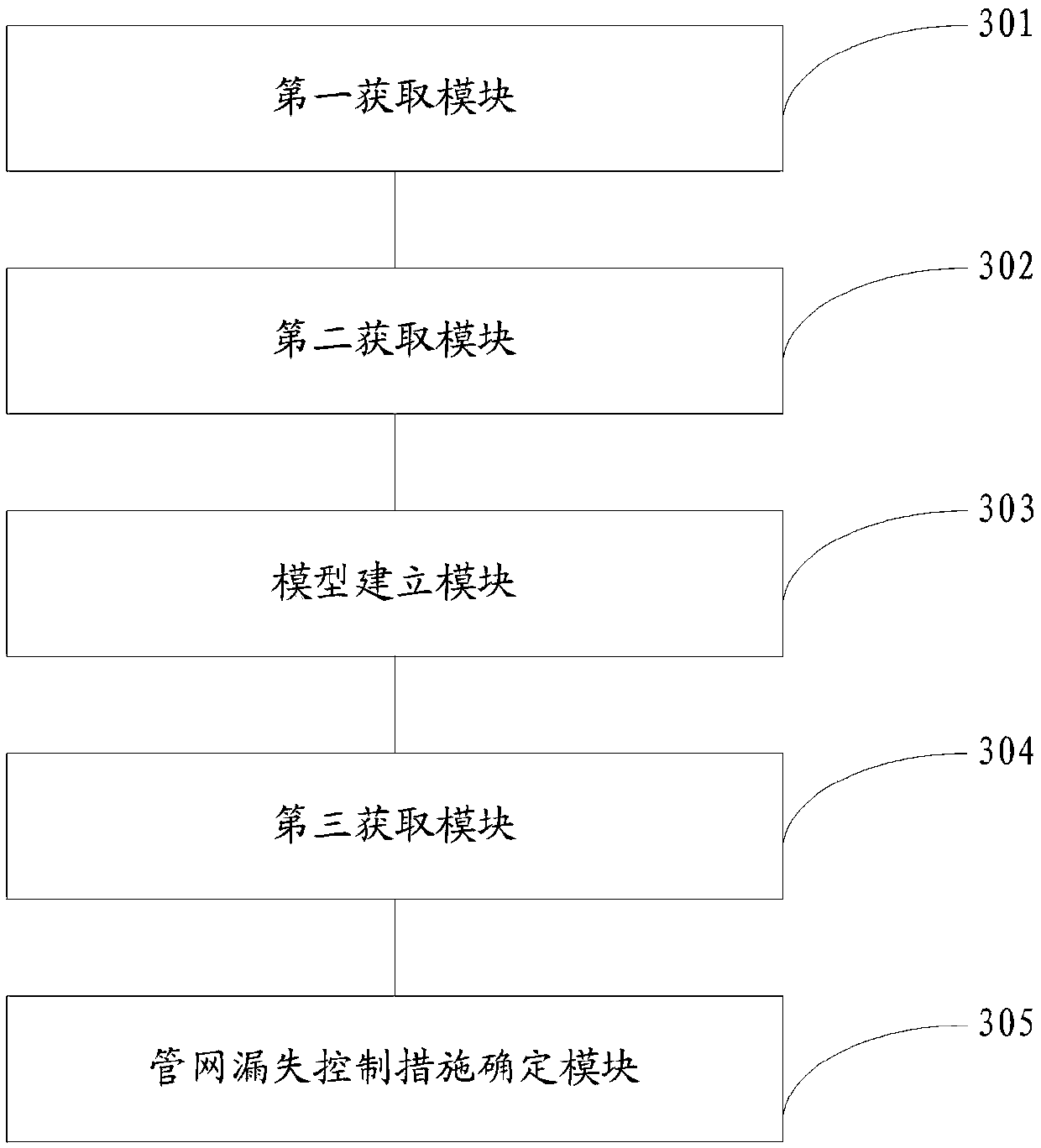

[0115] Step 1: Select 20 independent metering areas in a pipe network, and count the total length L of cast iron pipes in each independent metering area a , total length of non-cast iron pipe L b , the number of users N;

[0116] Step 2: Monitor the flow and pressure of each independent metering area in real time for 7 consecutive days. The monitoring time interval is once every 15 minutes, and extract the daily minimum nighttime flow MNF and the corresponding pressure P when the minimum nighttime flow occurs;

[0117] Step 3: Calculate the average of the above 7-day MNF and P respectively, and denote it as MNF ave , P ave ;

[0118] Step 4: Established MNF with multiple linear regression method ave with L a , L b , N, P ave relationship, as follows: MNF ave =(0.02L a +0.00134L b +0.0336N)·P ave (1)

[0119] In the formula, MNF ave The unit is L / s; L a , L b The unit of N is km; the unit of N is thousand households; P ave The unit is m.

[0120] Step 5: Select a...

Embodiment 2

[0122] Analyze an independent metering area and count the total length L of cast iron pipes a = 9.3 km, L b =0.4km, N=7.36 thousand households, P ave =28.8m, put the above variables into the formula (1), get MN Fave,sim1 ==12.5L / s. While the actual MNF detected 1 =17.3L / s, it can be seen that MNF 1 >MNF ave,sim1 , indicating that the current leakage situation in the independent measurement area is higher than it should be, and leakage detection should be carried out.

Embodiment 3

[0124] Analyze an independent metering area and count the total length L of cast iron pipes a = 3.7km, L b = 0km, N = 2.33 thousand households, P ave =35.7m, put the above variables into formula (1), and get MNF ave,sim1 =5.44L / s. While the actual MNF detected 1 =9L / s, it can be seen that MNF 1 >MNF ave,sim1 , indicating that the current leakage situation in the independent measurement area is higher than it should be, and leakage detection should be carried out. In addition, the current pipe network pressure P ave (35.7m) higher than the local pressure standard value P 2 (28m), the P 2 Substitute into P in formula (1) ave , get MNF ave,sim2 =4.26L / s, with the above MNF ave,sim1 =5.44L / s, the leakage can be further reduced by 1.18L / s, and 37,000 cubic meters of water can be saved throughout the year. Assuming that the unit water supply cost is 3 yuan / cubic meter, the benefits obtained by the pressure control of the independent metering area It is 3.7*3=111,000 yuan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com