A method for judging the failure cause of plugging zone of fractured reservoir leakage plugging material

A technology of plugging materials and judging methods, applied in the directions of analysis materials, instruments, measuring devices, etc., can solve the problems of instability of plugging belts, leakage failures, lack of plugging belts, etc., and achieves low economic cost, simple operation process, The effect of improving leakage control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

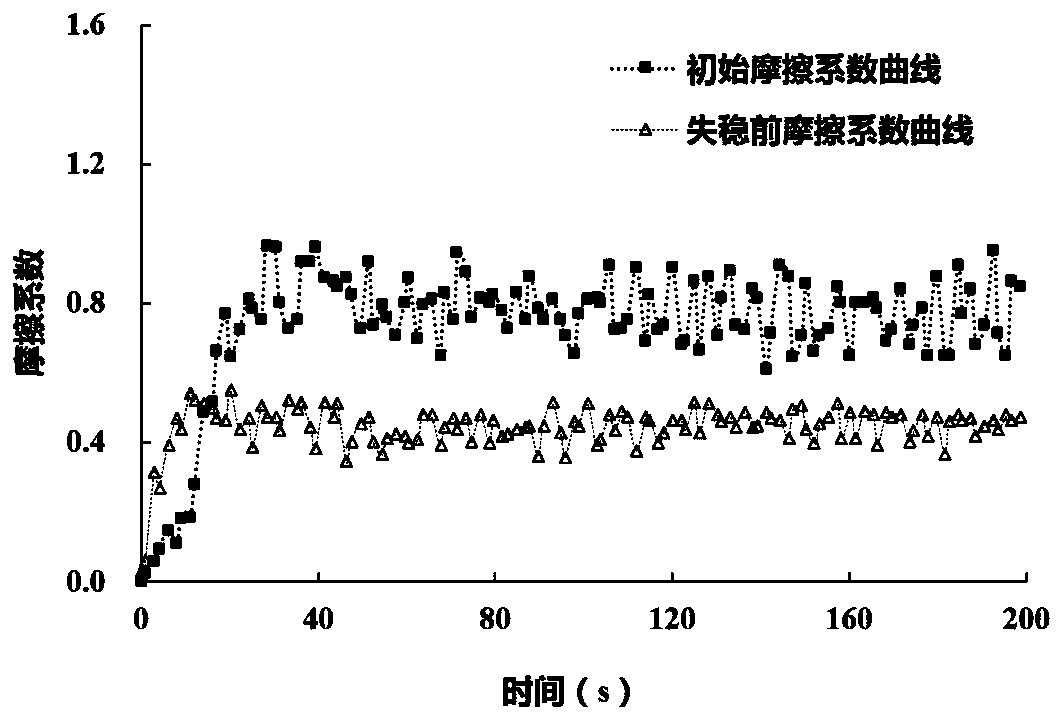

[0028] In order to verify the reliability of the present invention, materials commonly used in drilling sites were selected as experimental plugging materials, and indoor experiments on crack plugging were carried out to analyze the friction characteristics of the plugging material before the plugging zone was unstable. Reasons are determined. The specific operation steps are as follows:

[0029] a. The commonly used plugging materials in the drilling site are divided into three types: rigid materials, elastic materials and fibers, and the selected plugging materials are divided into three types: a single rigid material, a combination of rigid materials and elastic materials, and a combination of rigid materials and fibers ;

[0030] b. Mix the plugging materials of each combination in step a evenly according to a certain ratio, and divide them into two parts. One part is tested for the initial friction coefficient, and the other part is added to the drilling fluid at 150 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com