Steel water stone separation blocking dam and mounting method thereof

A technology for separation and installation of water and stone, applied in dams, protection devices, embankments, etc., can solve problems such as poor water permeability, inconvenient maintenance and cleaning, and achieve the effects of good water permeability, material saving, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

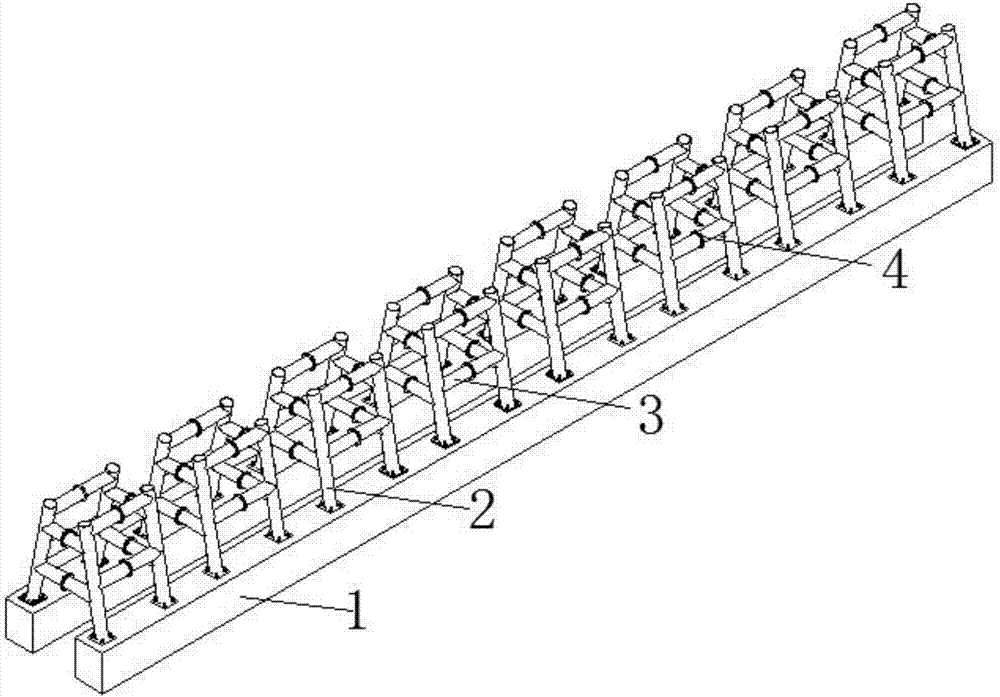

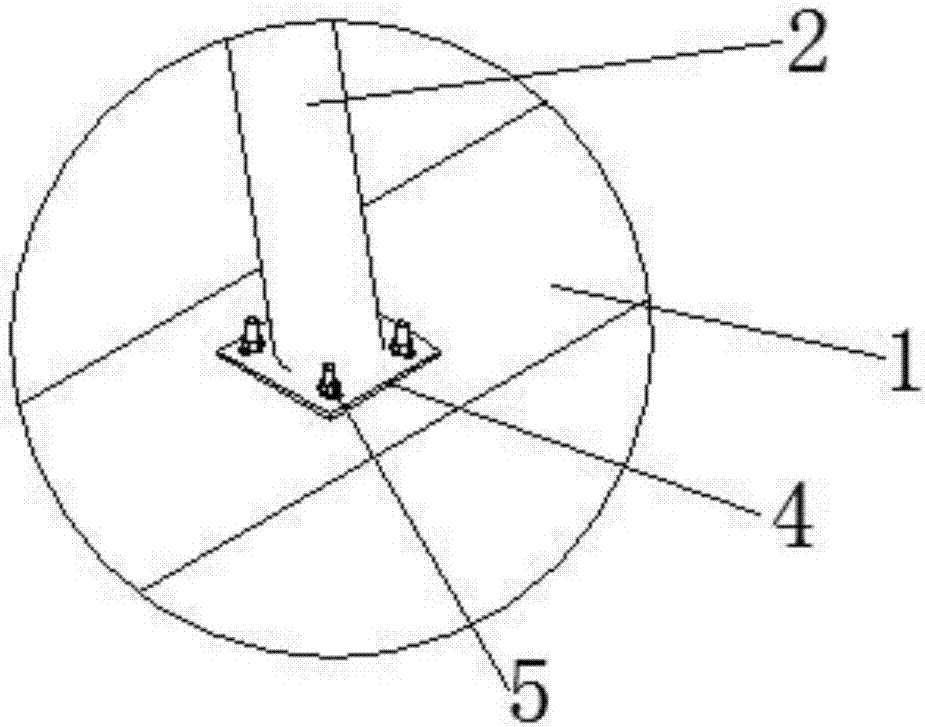

[0035] like figure 1 , figure 2 As shown, a steel-made water-rock separation retaining dam includes a concrete foundation 1 and a retaining dam body structure arranged on the concrete foundation 1; the retaining dam body structure includes two retaining dam body steel pipe groups; the retaining dam body steel pipe The group includes at least two retaining dam body steel pipes 2 arranged in parallel on a plane; two said retaining dam body steel pipe groups are symmetrically fixed on the concrete foundation 1; each adjacent two retaining dam body steel pipes 2 They are connected by a fixed pipe 3 ; the lower end of the steel pipe 2 of the retaining dam body is welded with a horizontal base bottom plate 4 , and the base bottom plate 4 and the concrete foundation 1 are fixedly connected by an anchor rod 5 .

Embodiment 2

[0037] like figure 1 , figure 2 As shown, a steel-made water-rock separation retaining dam includes a concrete foundation 1 and a retaining dam body structure arranged on the concrete foundation 1; the retaining dam body structure includes two retaining dam body steel pipe groups; the retaining dam body steel pipe The group includes at least two retaining dam body steel pipes 2 arranged in parallel on a plane; two said retaining dam body steel pipe groups are symmetrically fixed on the concrete foundation 1; each adjacent two retaining dam body steel pipes 2 They are connected by a fixed pipe 3 ; the lower end of the steel pipe 2 of the retaining dam body is welded with a horizontal base bottom plate 4 , and the base bottom plate 4 and the concrete foundation 1 are fixedly connected by an anchor rod 5 .

[0038] The two ends of the fixed pipe 3 are welded on the steel pipe 2 of the dam body; the middle part of the fixed pipe 3 is divided into two sections, the two sections o...

Embodiment 3

[0040] like figure 1 , figure 2 As shown, a steel-made water-rock separation retaining dam includes a concrete foundation 1 and a retaining dam body structure arranged on the concrete foundation 1; the retaining dam body structure includes two retaining dam body steel pipe groups; the retaining dam body steel pipe The group includes at least two retaining dam body steel pipes 2 arranged in parallel on a plane; two said retaining dam body steel pipe groups are symmetrically fixed on the concrete foundation 1; each adjacent two retaining dam body steel pipes 2 They are connected by a fixed pipe 3 ; the lower end of the steel pipe 2 of the retaining dam body is welded with a horizontal base bottom plate 4 , and the base bottom plate 4 and the concrete foundation 1 are fixedly connected by an anchor rod 5 .

[0041] The two ends of the fixed pipe 3 are welded on the steel pipe 2 of the dam body; the middle part of the fixed pipe 3 is divided into two sections, the two sections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com