A kind of preparation method of imitation volcanic rock porous material

A porous material and volcanic rock technology, applied in the fields of architectural decoration and architectural landscape materials, can solve the problems of long production cycle, limited primary strength, easy cracking of products, etc., and achieve high mechanical and durability performance, fast hardening time and good durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

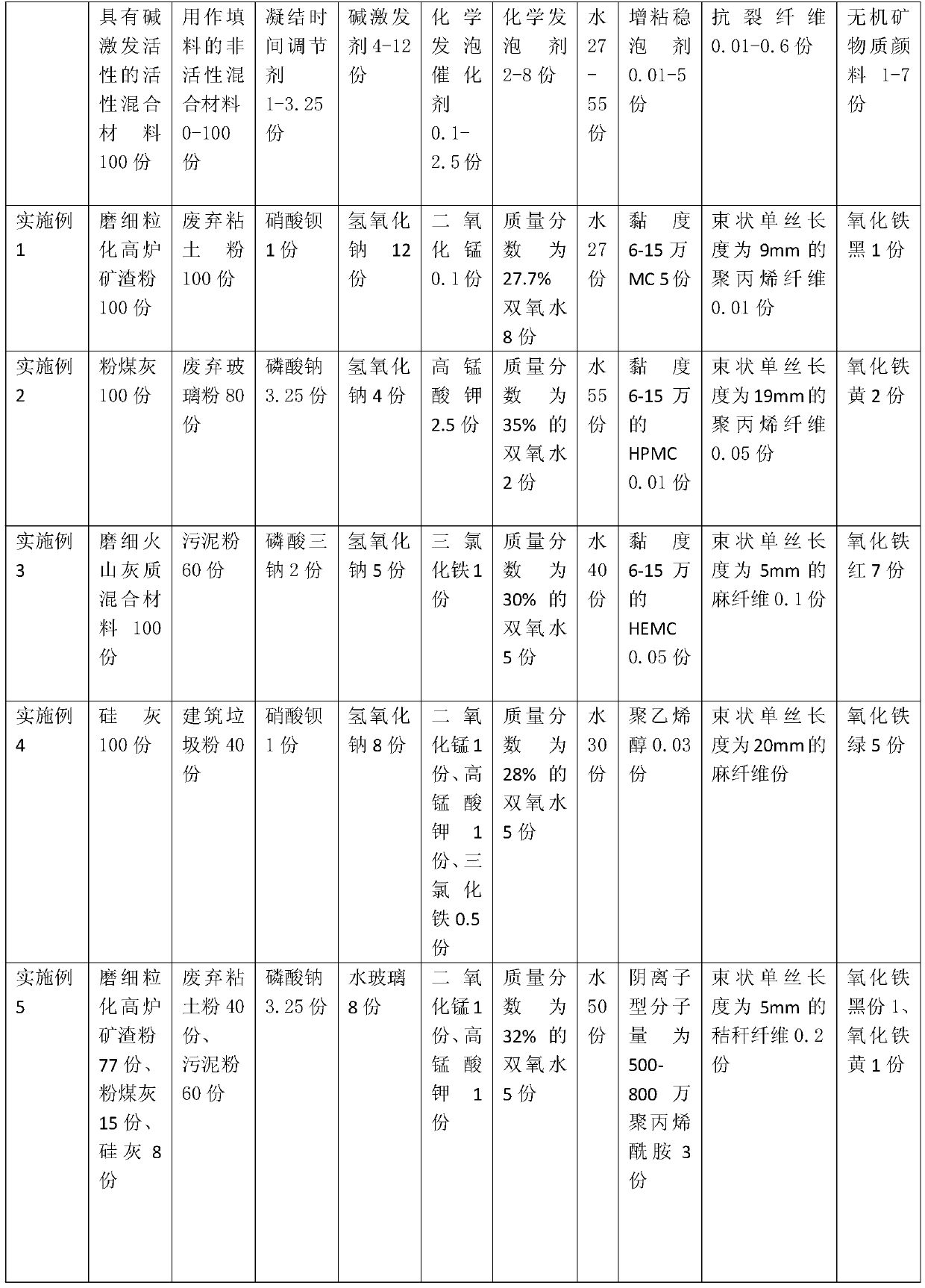

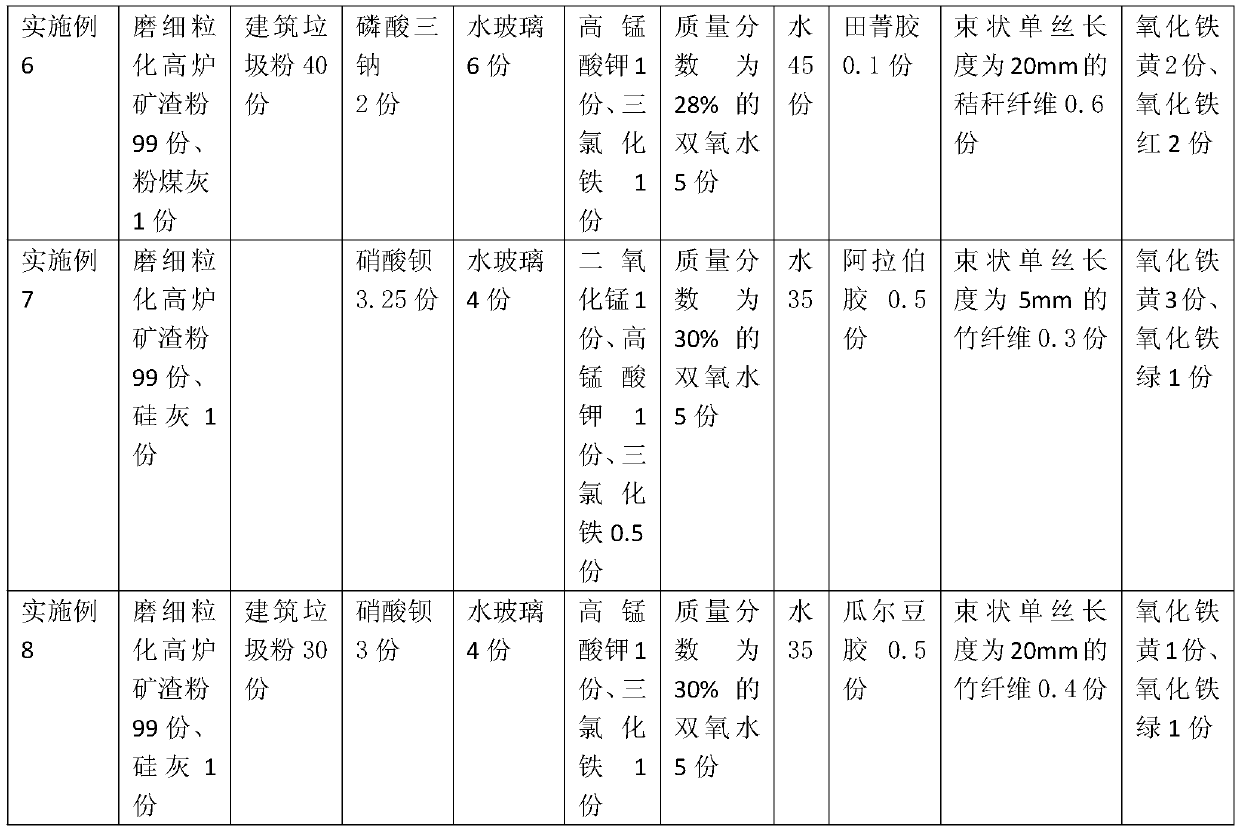

Examples

Embodiment 9

[0038] A method for preparing a porous material imitating volcanic rock, comprising the steps of:

[0039] (1) Weigh the active mixed material with alkali excitation activity by each component and parts by weight in the embodiment 1 of table 1; The inactive mixed material used as filler; Setting time regulator; Alkali activator; Chemical foaming Catalyst; chemical blowing agent; water; viscosity increasing and foam stabilizing agent; anti-cracking fiber; inorganic mineral pigment;

[0040] (2) The active mixed material with alkali excitation activity; the inactive mixed material used as filler; the setting time regulator, anti-crack fiber, and inorganic mineral pigment are placed in a stirring container, and the mixture is uniformly stirred; the alkali activator , chemical foaming catalyst and viscosifying foam stabilizing agent are respectively dissolved in weighed water, and stirred evenly;

[0041] (3) Add the alkali activator aqueous solution, the viscosity-increasing foa...

Embodiment 10

[0044] A method for preparing a porous material imitating volcanic rock, comprising the steps of:

[0045] (1) Weigh the active mixed material with alkali excitation activity by each component and parts by weight in the embodiment 2 of table 1; the inactive mixed material used as filler; setting time regulator; alkali activator; chemical foaming Catalyst; chemical blowing agent; water; viscosity increasing and foam stabilizing agent; anti-cracking fiber; inorganic mineral pigment;

[0046] (2) The active mixed material with alkali excitation activity; the inactive mixed material used as filler; the setting time regulator, anti-crack fiber, and inorganic mineral pigment are placed in a stirring container, and the mixture is uniformly stirred; the alkali activator , chemical foaming catalyst and viscosifying foam stabilizing agent are respectively dissolved in weighed water, and stirred evenly;

[0047] (3) Add the alkali activator aqueous solution, the viscosity-increasing foa...

Embodiment 11

[0050] A method for preparing a porous material imitating volcanic rock, comprising the steps of:

[0051] (1) Weigh the active mixed material with alkali excitation activity by each component and parts by weight in the embodiment 3 of table 1; The inactive mixed material used as filler; Setting time regulator; Alkali activator; Chemical foaming Catalyst; chemical blowing agent; water; viscosity increasing and foam stabilizing agent; anti-cracking fiber; inorganic mineral pigment;

[0052] (2) The active mixed material with alkali excitation activity; the inactive mixed material used as filler; the setting time regulator, anti-crack fiber, and inorganic mineral pigment are placed in a stirring container, and the mixture is uniformly stirred; the alkali activator , chemical foaming catalyst and viscosifying foam stabilizing agent are respectively dissolved in weighed water, and stirred evenly;

[0053] (3) Add the alkali activator aqueous solution, the viscosity-increasing foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com