Automatic and quick rope recovery device

A fast and automatic technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of low efficiency of manual recycling, and achieve the effect of improving efficiency and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

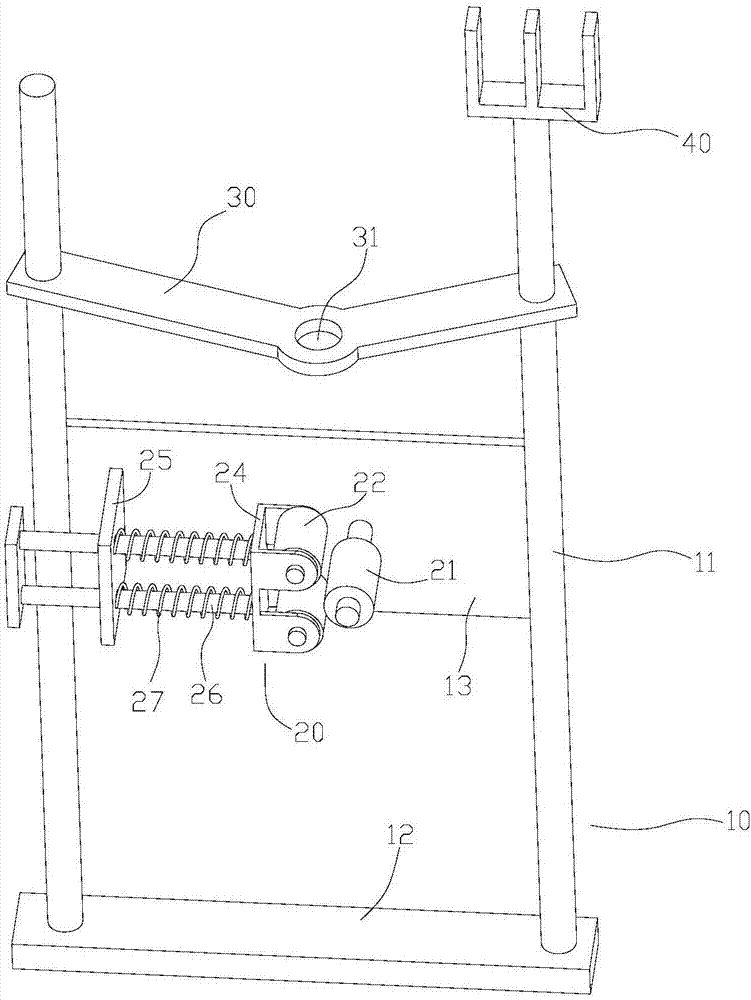

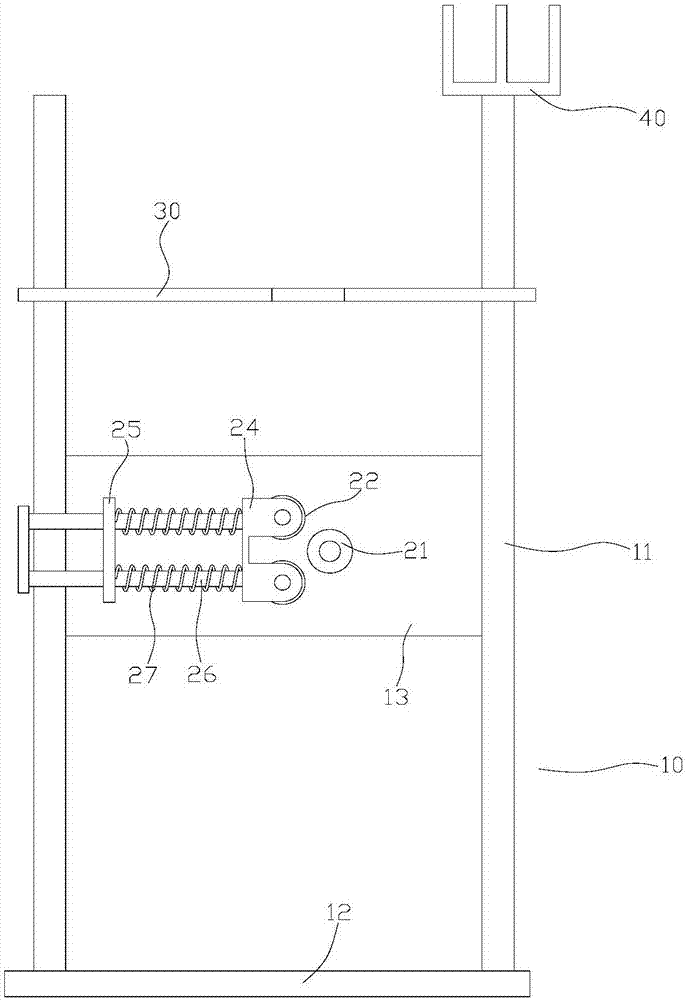

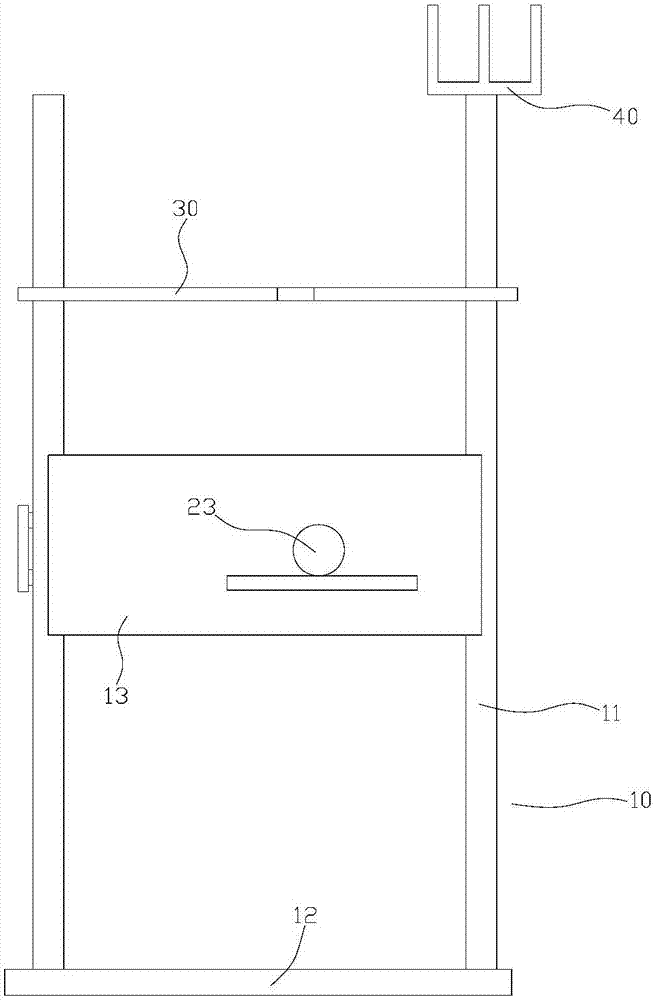

[0018] Please refer to figure 1 with figure 2 , an automatic fast rope retracting device, which includes a support frame 10 and a rope pulling mechanism 20.

[0019] The support frame 10 includes two vertical columns 11 and a base plate 12 , the two vertical columns 11 are fixed on the base plate 12 at intervals, and a vertical plate 13 is fixed between the middle parts of the two vertical columns 11 .

[0020] The rope pulling mechanism 20 is located at the middle part of the support frame 10; the rope pulling mechanism 20 includes a driven roller shaft 22 and a driving roller shaft 21 driven by a motor 23, and the driving roller shaft 21 is coaxial with the driven roller shaft 22 The outer surfaces of the driving roller shaft 21 and the driven roller shaft 22 are wrapped with a rubber layer; wherein, the driving roller shaft 21 and the driven roller shaft 22 are fixed on the front of the vertical plate 13, and the motor 23 Be fixed on the back side of vertical plate 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com