Longitudinal beam structure of vehicle body

A technology of longitudinal beams and car bodies, applied in the field of car body safety structures, can solve problems such as ineffective unloading, increased weight, unfavorable light weight, etc., to achieve the effect of optimizing the transmission path and ensuring the amount of intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

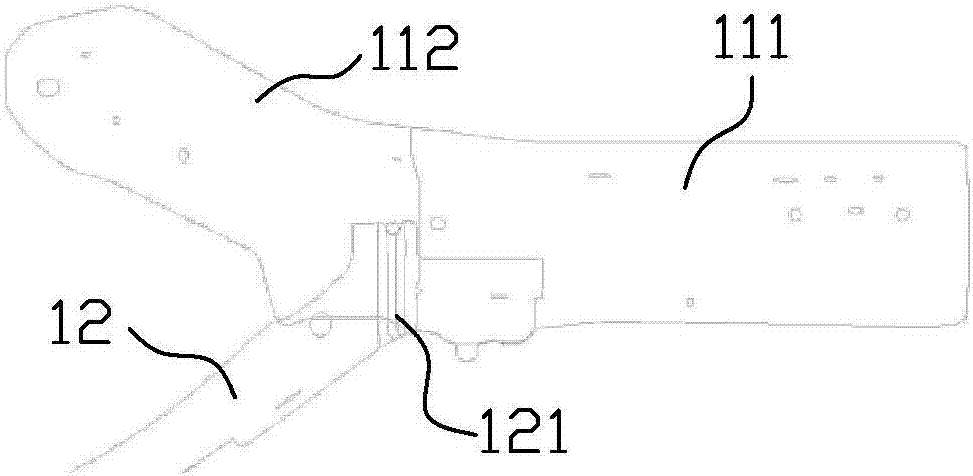

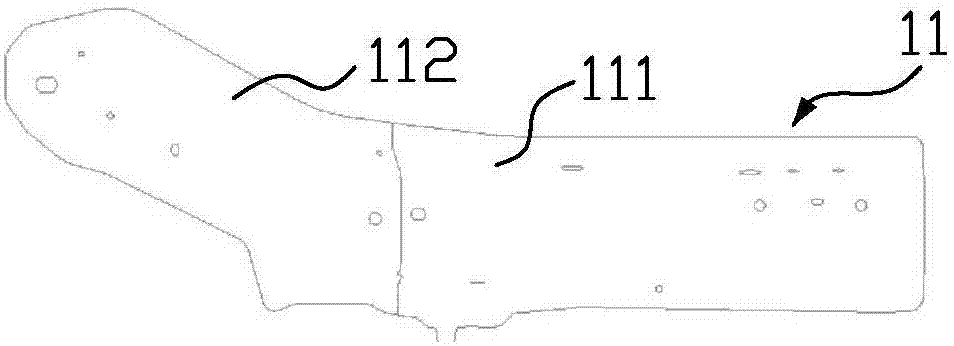

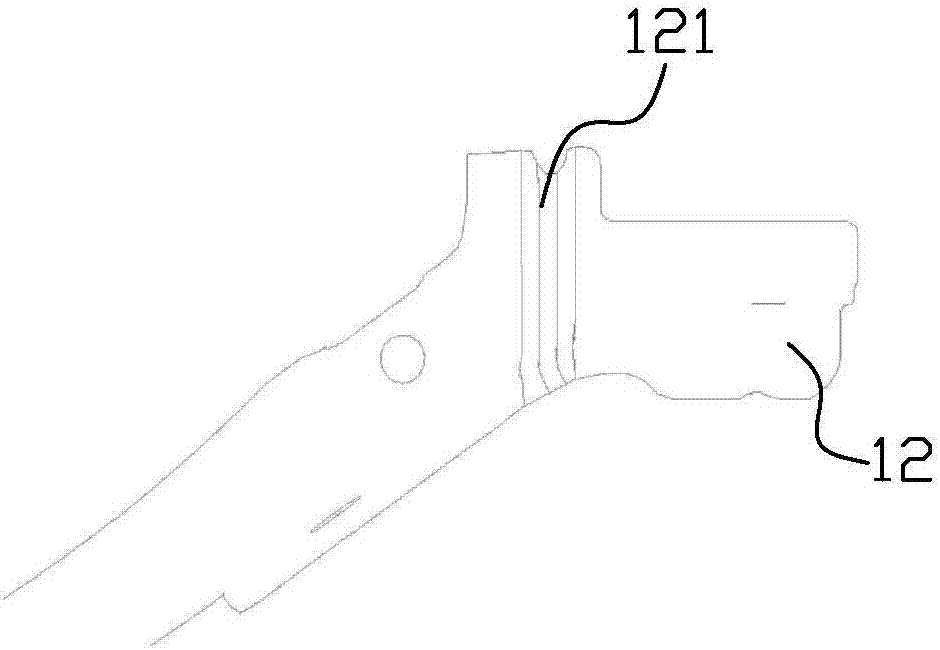

[0016] Such as Figure 1 to Figure 4 As shown, a vehicle body longitudinal beam structure includes a front longitudinal beam 10 extending in the direction of the automobile body and a front wall cross member 20 connected between the front longitudinal beams 10. The front longitudinal beam 10 includes a longitudinal beam front section 11 and the longitudinal beam. The front section 11 of the beam is connected to the rear section 12 of the longitudinal beam. Specific as figure 2 As shown, the front section 11 of the longitudinal beam includes a front half 111 and a rear half 112, and the front half 111 and the rear half 112 are welded and connected as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com