Shaft transmission mechanism of motorcycle

A shaft transmission and motorcycle technology, applied to motorcycles, wheeled transmissions, rotary transmissions, etc., can solve the problems of insufficient compact structure and large axial size, and achieve compact structure, small lateral size, and reduced peripheral size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

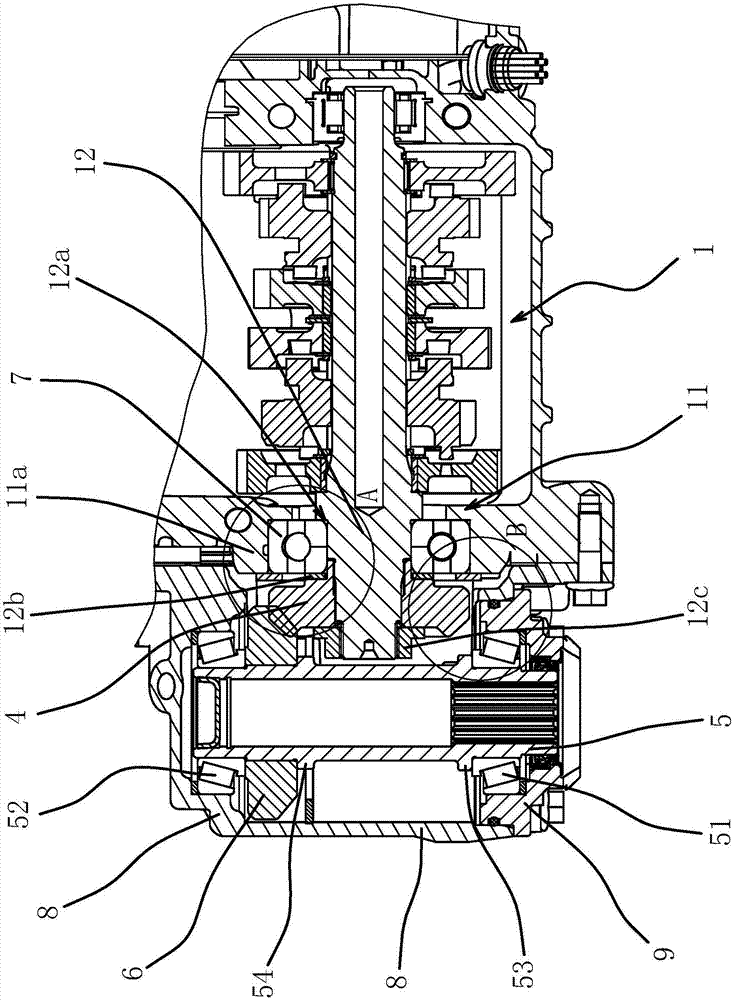

[0032] Such as figure 1 , figure 2 As shown, the shaft transmission mechanism of this motorcycle includes a speed change mechanism 1, a transmission shaft 2 and a driving rear axle 3. The transmission shaft 2 extends along the front and rear direction of the vehicle body. One end of the transmission shaft 2 is connected with the driving rear axle 3. Including the output shaft 12 and the transmission case 11, the output shaft 12 extends along the left and right direction of the vehicle body and passes through the transmission case 11, the outer end of the output shaft 12 is sleeved with the input bevel gear 4, and the other end of the transmission shaft 2 is sleeved The driven shaft 5 is connected, and the output bevel gear 6 is sleeved on the driven shaft 5. The input bevel gear 4 and the output bevel gear 6 are meshed and the axis angle between the two is 90°. The input bevel gear 4 and the transmission housing 11 A four-point contact ball bearing 7 is arranged between them...

Embodiment 2

[0039] A motorcycle, the motorcycle includes a shaft transmission mechanism, the shaft transmission mechanism is the same as the first embodiment. By adopting the above-mentioned shaft transmission mechanism, the motorcycle can ensure uniform cooling of the engine, and the structure is compact to facilitate the overall spatial arrangement of the motorcycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com