Support suspension system and electric car

A technology for suspension systems and electric vehicles, which is applied in the direction of electric power devices, power devices, vehicle components, etc., and can solve problems such as poor safety of high-voltage electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

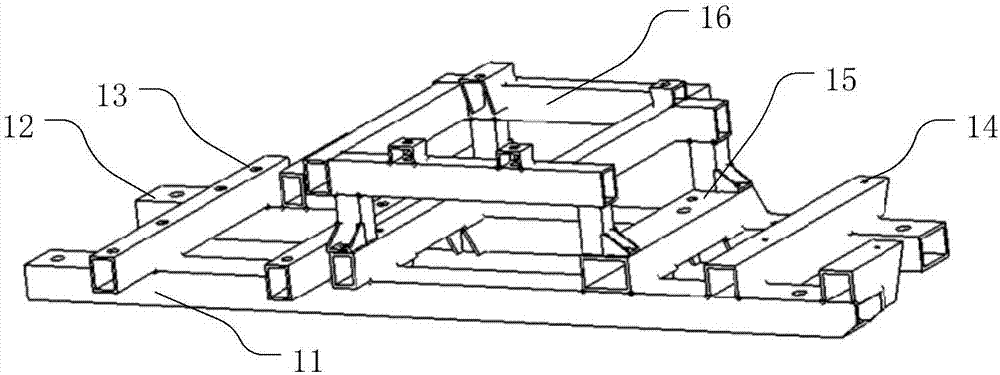

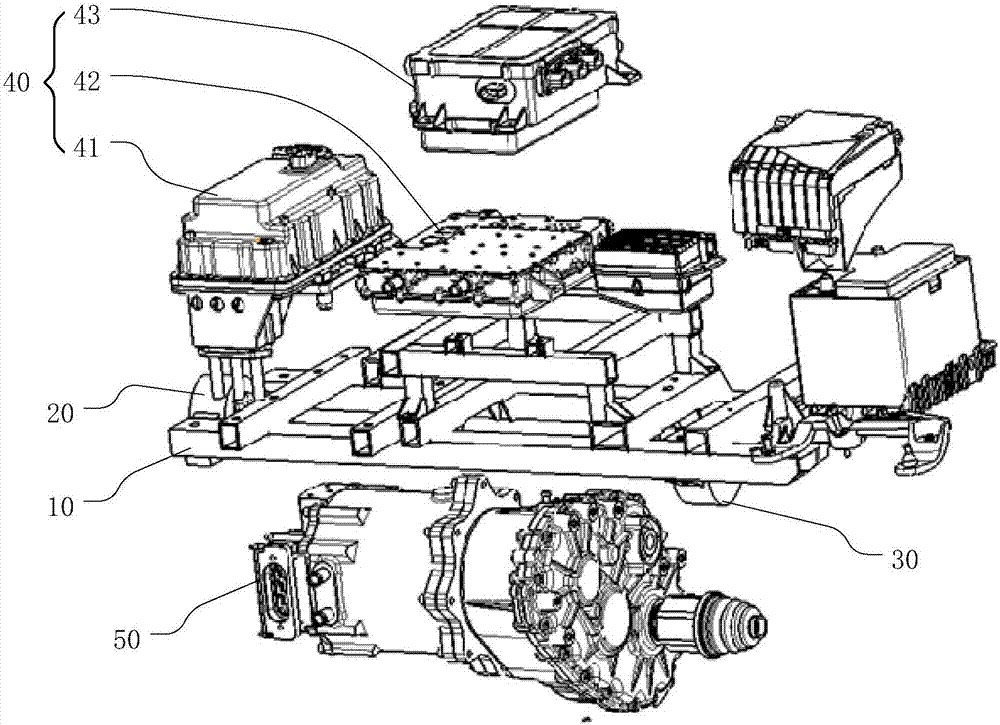

[0029] figure 1 It is a structural schematic diagram of an embodiment of a support suspension system provided by the present invention.

[0030] The support and suspension system provided in this embodiment is applied to an electric vehicle, and is specifically arranged in an engine compartment of the electric vehicle. This kind of electric vehicle is a pure electric vehicle driven purely by electricity, so facilities such as drive motors and high-voltage electrical components are arranged in the engine compartment. And there is a vehicle body longitudinal beam (not shown) which supports the vehicle body in the electric vehicle, and the vehicle body longitudinal beam includes a left longitudinal beam on the left side and a right side beam on the right side.

[0031] The body longitudinal beam is the key part of the frame, and the frame is the most important load-bearing part in the car, so the body longitudinal beam plays an important role in the car. The side beam frame of t...

Embodiment 2

[0044] This embodiment also provides an electric vehicle, the electric vehicle includes the supporting suspension system provided in the above embodiment, and the system is used to carry the high-voltage electrical components and the driving motor of the electric vehicle. The system specifically includes motor left mount, motor right mount and electrical bracket. The two ends of the electrical bracket are respectively fixed on the left longitudinal beam and the right longitudinal beam; the high-voltage electrical parts are fixed on the upper part of the electrical bracket; the left suspension of the motor is fixed on the left longitudinal beam; the right suspension of the motor is fixed on the electrical bracket One end fixed to the right longitudinal beam; the two ends of the driving motor are respectively fixed on the left motor mount and the motor right mount, and are located below the electrical bracket. Generally speaking, the strength of the drive motor is the highest, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com