Car radial spare tire

A spare tire and radial technology, used in special tires, tire parts, tire treads/tread patterns, etc., can solve the problems of heavy relative weight of full-size tires, inconsistent wear of left and right tires, and unsuitable long-term use. Anti-skid performance, reduce body weight, improve wet grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

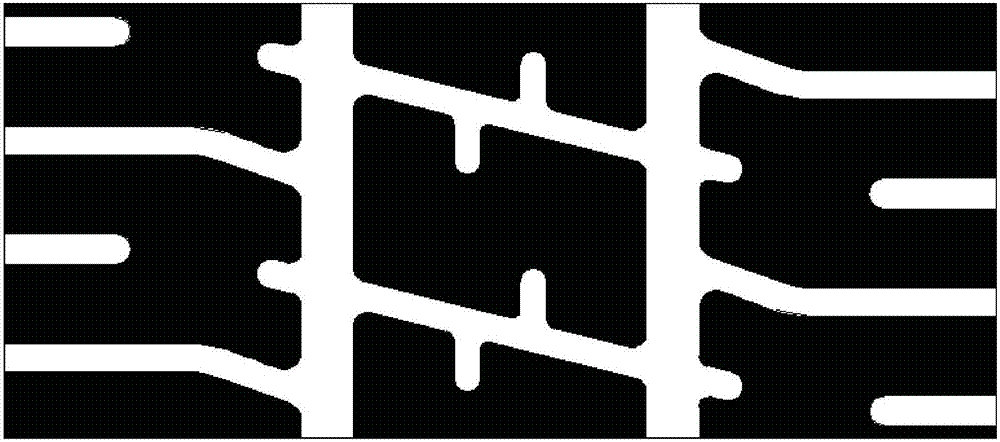

[0032] In order to achieve the purpose of the present invention, figure 1 A partially developed plan view of a tread portion according to an embodiment of the present invention is shown. The tread pattern of this invention is circumferentially continuous in the vertical direction in the drawing. The first circumferential main groove 1a and the second circumferential main groove 1b are respectively arranged in the direction from left to right in the figure on the tread; the first circumferential main groove 1a, the second circumferential main groove 1b, and the oblique straight groove 3 divide the S-shaped pattern block 2b; the first circumferential main groove 1a and the broken line groove 4 define the first I-shaped pattern block 2a; the second circumferential main groove 1b and the broken line groove 4 define the second I-shaped pattern block 2c.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com