Printing numerically-controlled flame cutting machine

A flame cutting machine and flame cutting technology, applied in the direction of gas flame welding equipment, welding equipment, metal processing, etc., can solve the problem that the oxygen acetylene tube cannot be adapted to the on-site installation and operation, affects the progress of the cutting and blanking process, and cannot be used normally. problems, to achieve the effect of saving reclaiming time, prolonging the service life and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

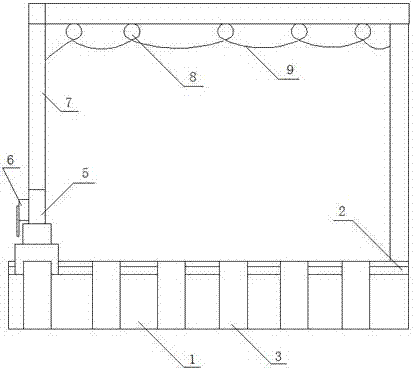

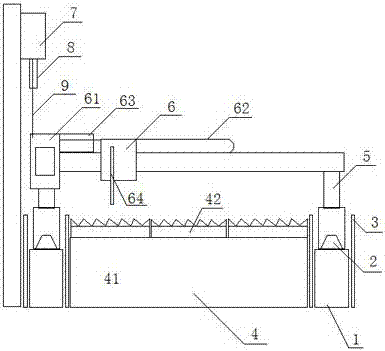

[0015] Such as figure 1 A printing type numerical control flame cutting machine shown includes two cutting machine tracks 2 laid in parallel, and a laying platform 1 is installed under each track, and the lower part of the laying platform 1 is fixed on the ground; The plate 3 and the protective plate 3 are higher than the cutting machine track 2; the cutting table 4 includes a cutting bench and several zigzag strip groups 42 installed on the cutting bench 41; the welding beam frame 5 is arranged on two cutting machine rails 2 , the flame cutting assembly 6 is installed on the crossbeam of the welded beam frame, at the air inlet end of the flame cutting assembly 6, a hanger 7 is set on the side parallel to the track 2 of the cutting machine, a pulley block 8 is arranged on the hanger 7, and the air pipe 9 is connected to the pulley block 8 .

[0016] The zigzag slat group 42 is composed of a plurality of zigzag slats arranged in parallel and at intervals.

[0017] The flame c...

Embodiment 2

[0021] A print-type numerical control flame cutting machine, including a self-made cutting machine track platform, using two 32# I-beams with a length of 6 meters and a gauge of 3 meters, placed in parallel, as a laying platform for the cutting machine track. In order to achieve the purpose of stabilizing the track laying platform, the upper and lower parts of the I-beam are welded to steel plates with a length of 6 meters, a width of 120 mm, and a thickness of 20 mm. The upper plane is milled with a milling machine to ensure flatness. A number of holes with a diameter of 20 mm are drilled on the lower plane and fixed on the ground with expansion bolts.

[0022] Considering that the lifting steel plate will hit the track of the cutting machine, causing track damage and affecting the normal use of the cutting machine, 6 pieces of 350x200x10 mm steel plates are welded on the outside of the two track platforms, with a spacing of 800 mm and the upper end protruding 150 mm; The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com