Method and device for preparing highly pure hydrogen and carbon monoxide

A carbon monoxide, high-purity technology, applied in the directions of carbon monoxide, chemical instruments and methods, separation methods, etc., can solve the problems of large floor space, high investment and high energy consumption, and achieve the effect of saving space, reducing investment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with specific examples.

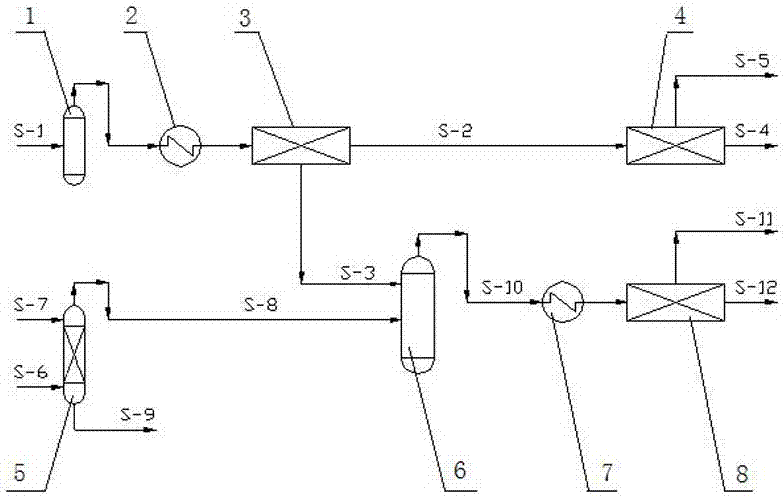

[0018] like figure 1 As shown, the device for producing high-purity hydrogen and carbon monoxide from the carbon monoxide-rich tail gas after synthesis gas and ethanol synthesis includes: a hydrogen production system and a carbon monoxide production system, wherein the hydrogen production system includes a gas-liquid separator connected in sequence. 1. Heater one 2, one-stage membrane separator 3 and pressure swing adsorption device 4, the carbon monoxide production system includes absorption tower 5, gas-liquid separator two 6, heater two 7, two-stage membrane separator 8 connected in sequence , the retentate side pipeline of the first-stage membrane separator is connected to the second gas-liquid separator.

[0019] In order to facilitate the understanding of the process route, the gas or gas-liquid mixture in each step of the production route is marked, specifically:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com