Tricycle feed manufacturing equipment

A technology for manufacturing equipment and tricycles, applied in feed, food science, application, etc., can solve the problems of unguaranteed milk quality, difficulty in realizing automatic breeding, and labor cannot be liberated, saving manpower and material resources, reducing breeding Cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

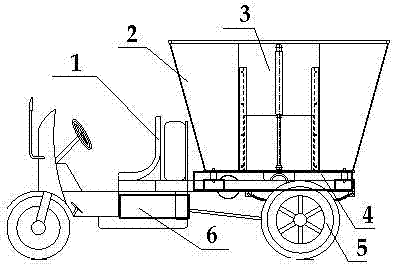

[0013] see figure 1 As shown, the present invention comprises a tricycle 1, a preparation machine casing 2, a motor 6 and a right-angle reducer 4, the preparation casing 2 is placed on the top of the tricycle 1, and a stirring mechanism 3 and a heating mechanism 3 are arranged in the preparation casing 2. mechanism, the lower part of the stirring mechanism 3 is connected with the right-angle reducer 4 through a transmission device. A clutch is provided between the engine 6 and the right-angle reducer 4, and the engine 6 and the right-angle reducer 4 are connected through the clutch. The tricycle 1 is provided with a rear wheel 5, and the rear wheel 5 is connected with the right-angle reducer 4 through the clutch. In this way, walking and stirring can be carried out step by step, reducing power consumption and failure rate. The tricycle 1 is provided with a two-way hydraulic pump, and the two-way hydraulic pump is connected with the preparation cabinet body 2 to provide power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com